Petrol engine variable valve timing device

A gasoline engine and gas timing technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex structure, high cost, and difficulty in popularization, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

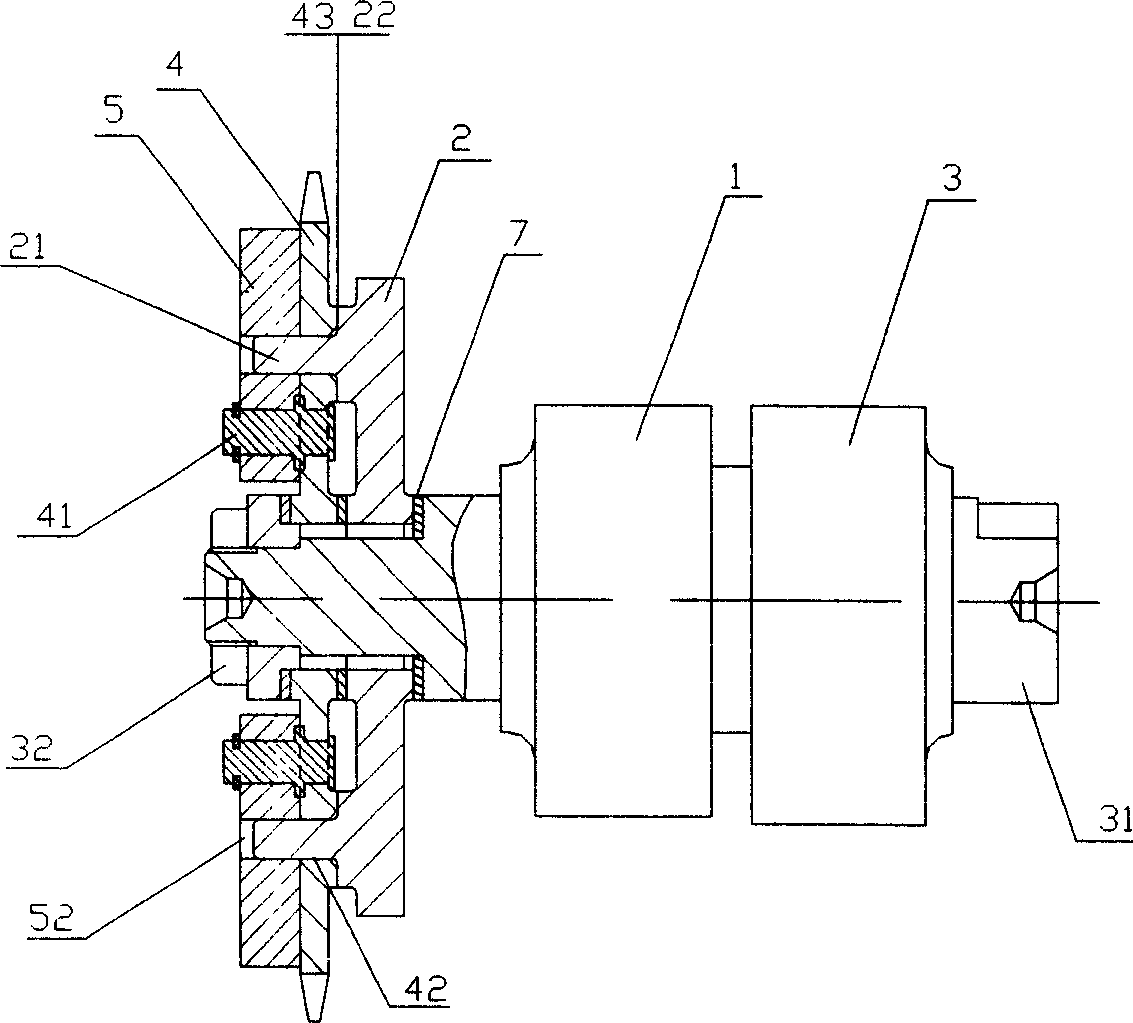

[0017] Such as figure 2 As shown, it is a partial cross-sectional schematic diagram of the structure of the gasoline engine variable valve timing mechanism according to Embodiment 1 of the present invention. From figure 2 It can be seen from the above that the present invention provides a variable valve timing mechanism for a gasoline engine, which includes a camshaft 31 on which a plurality of cams 1 and 3 are arranged, and the camshaft 31 is also provided with driven cams in sequence. Disc 2 and driving wheel 4, driven disc 2 is provided with boss 21, and driving wheel 4 is provided with arc-shaped groove 42 correspondingly, and this boss 21 inserts arc-shaped groove 42 and can slide in arc-shaped groove 42, makes The driven disc 2 can generate displacement relative to the driving wheel 4 .

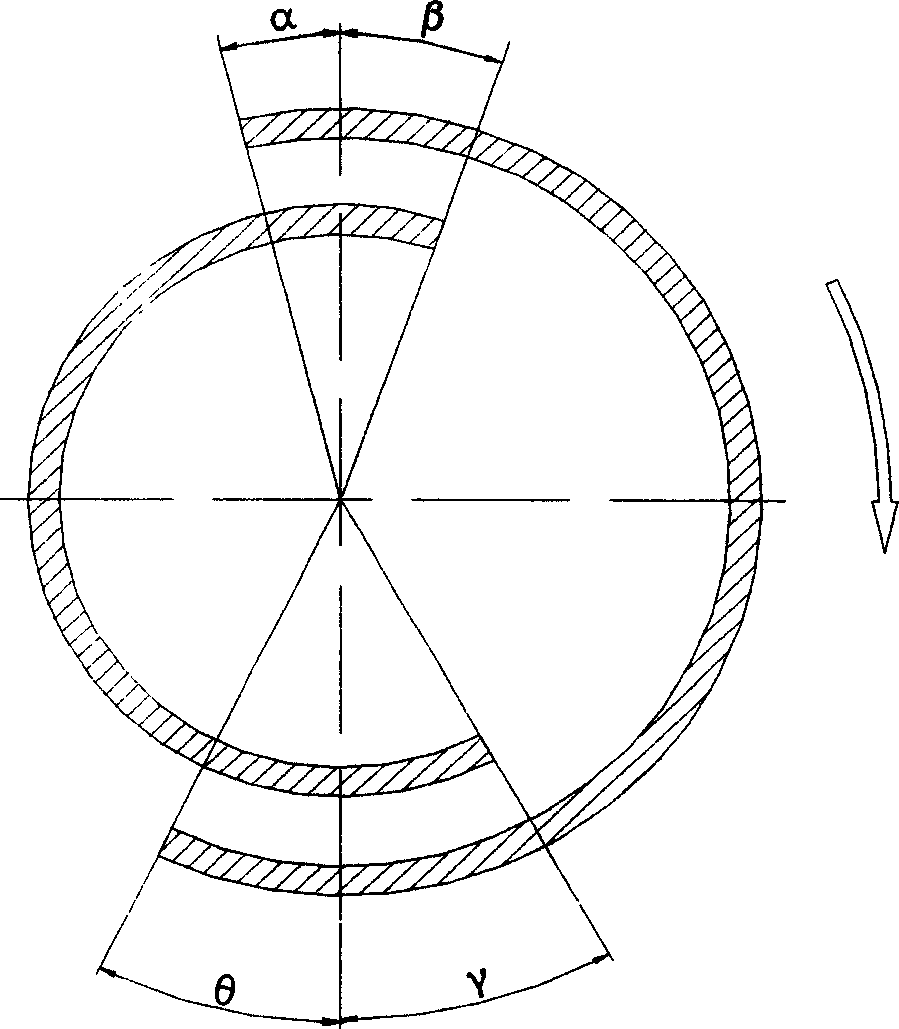

[0018] 4 and 5 are schematic diagrams of the moving positions of the centrifugal blocks when the engine of the present invention operates at low speed and high speed, respectively. ...

Embodiment 2

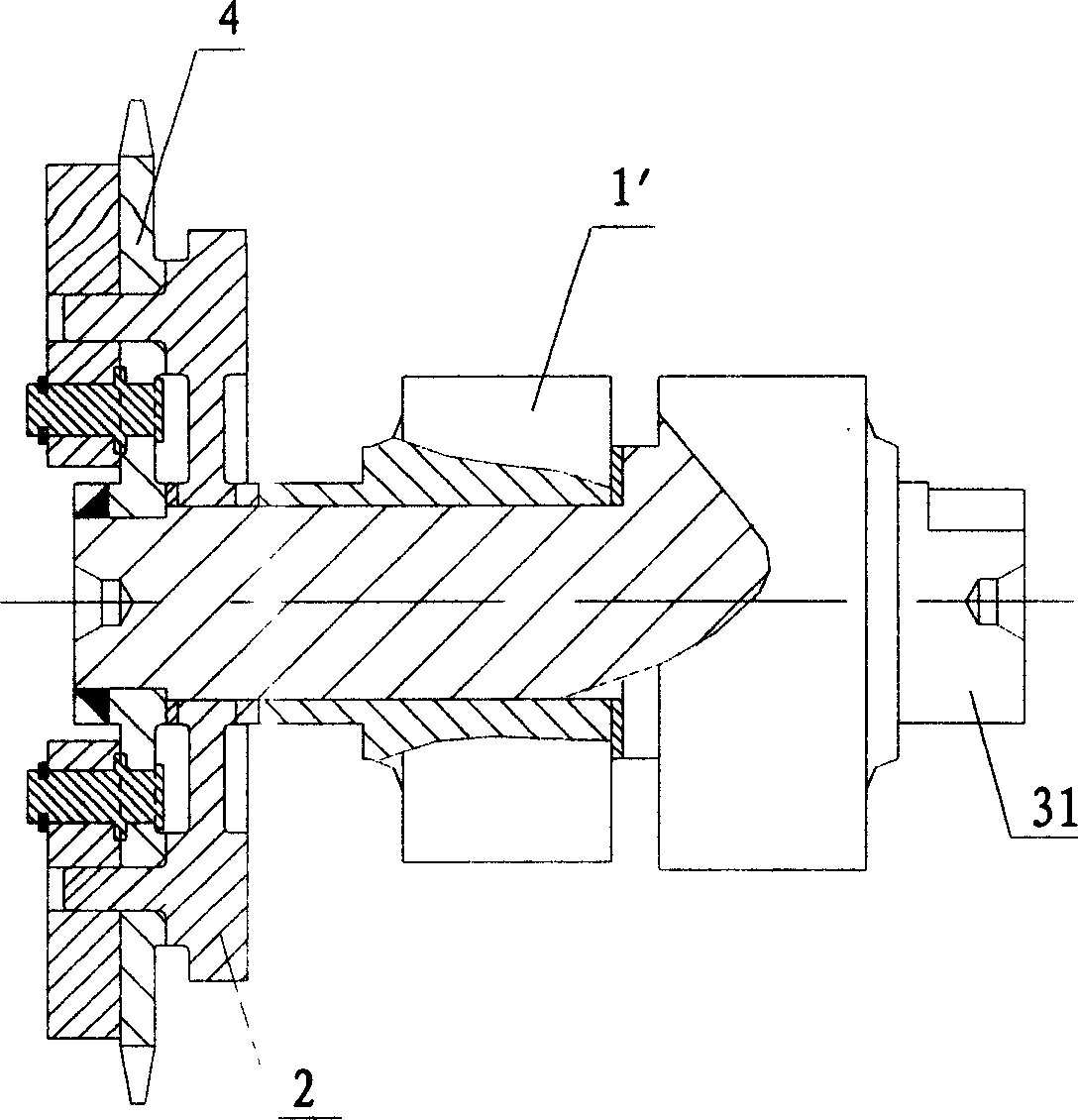

[0022] Such as image 3 As shown, it is a partial cross-sectional schematic diagram of the structure of the gasoline engine variable valve timing mechanism according to the second embodiment of the present invention. From image 3As can be seen in the figure, the cam can also be a free cam 1' sleeved on the camshaft 31, so that the free cam 1' rotates relative to the drive wheel 4. In order to connect stably, the contact surface of driven disc 2 and free cam 1' is a claw type connection. The difference between this embodiment and the first embodiment is that the end of the camshaft 31 and the drive wheel 4 are connected together by welding, therefore, there is no need to install the parts used in the first embodiment to prevent the axial direction of the parts. Movement limit device.

[0023] Other technical features of this embodiment are the same as those of Embodiment 1. Please refer to Embodiment 1 for specific technical solutions, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com