Process for lowering sulfur content in gasoline through hydrogen supply agent

A technology of hydrogen-donating agent and gasoline, which is applied in the field of reducing the sulfur content of gasoline and using the hydrogen-donating agent to reduce the sulfur content of gasoline. The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

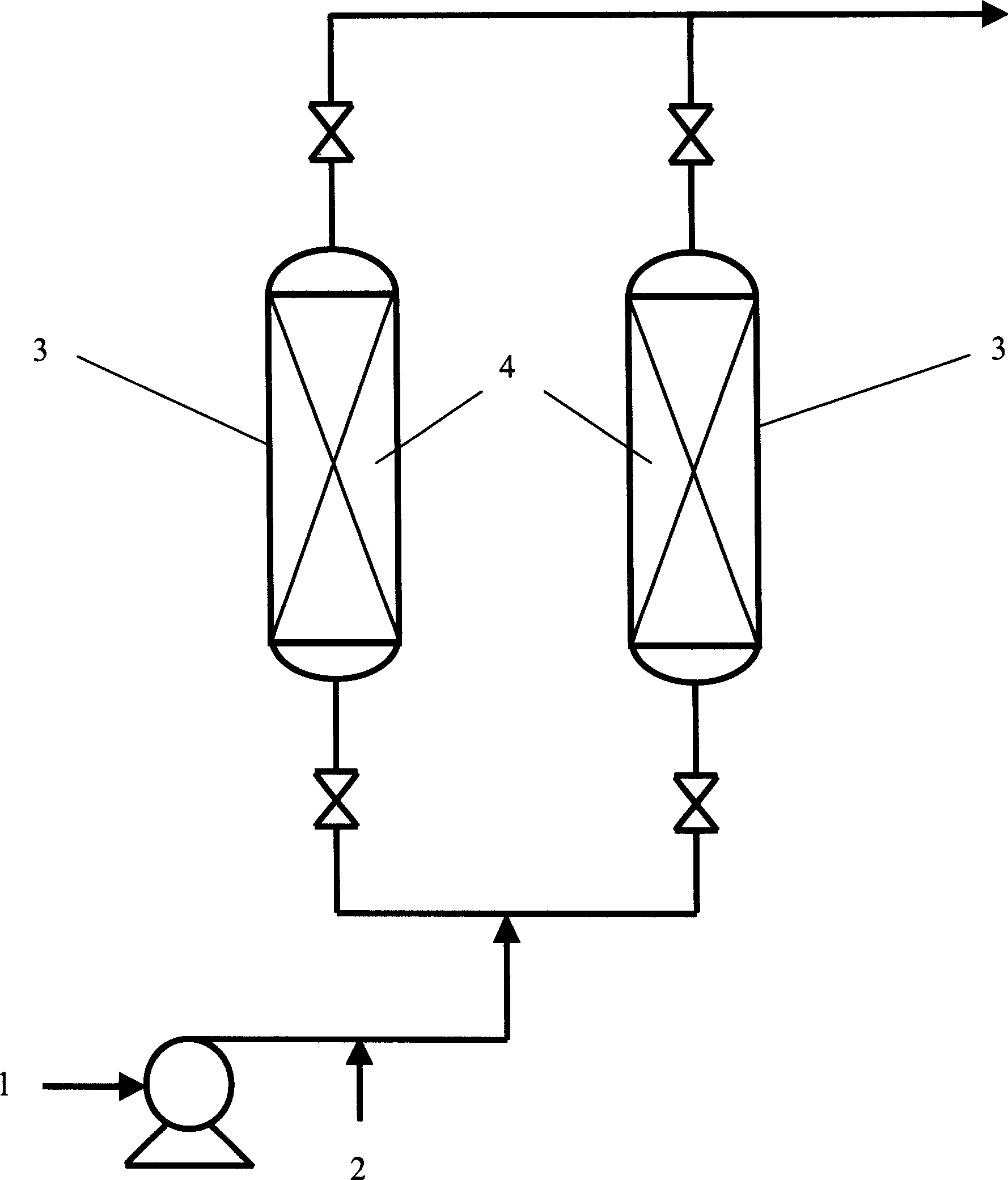

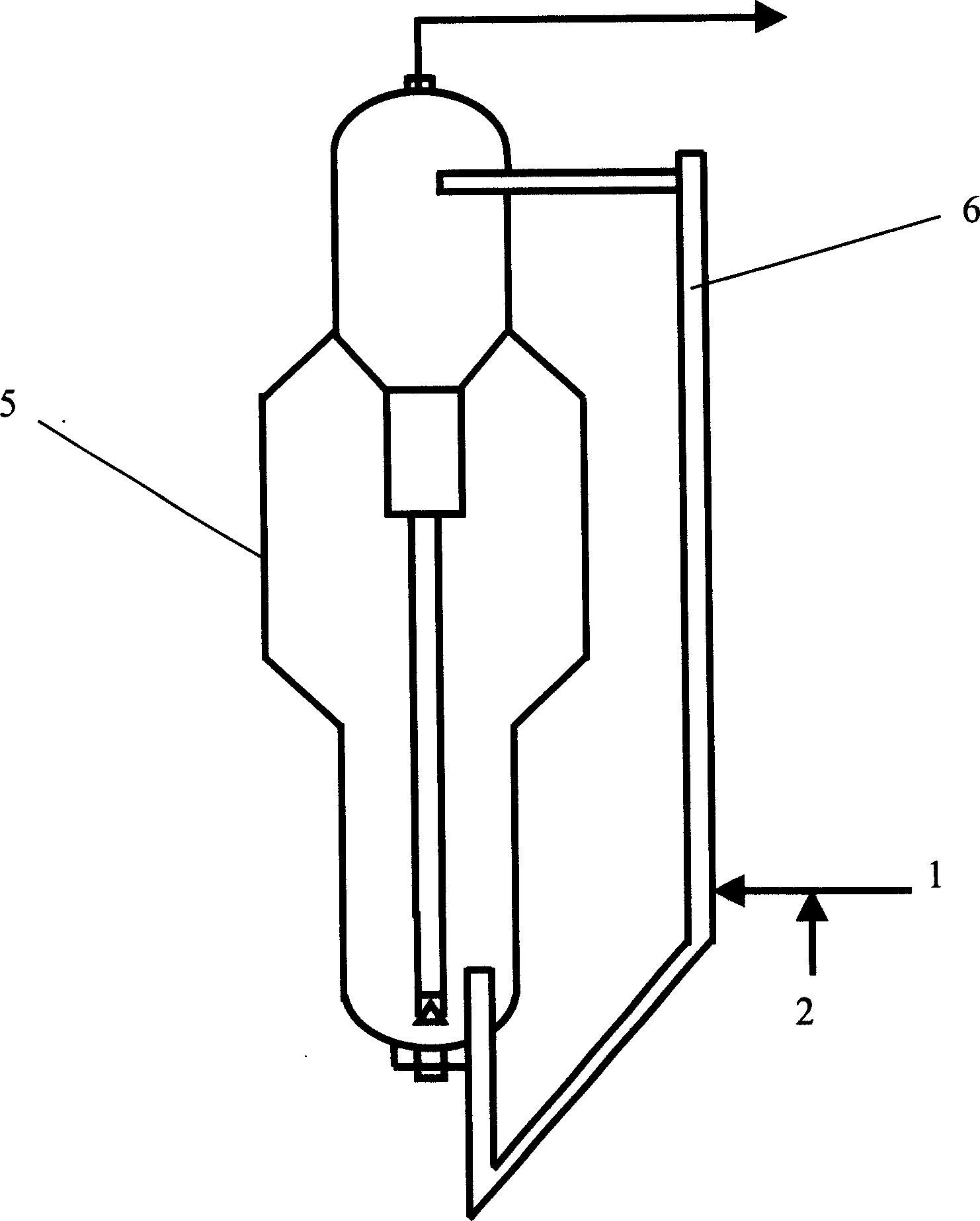

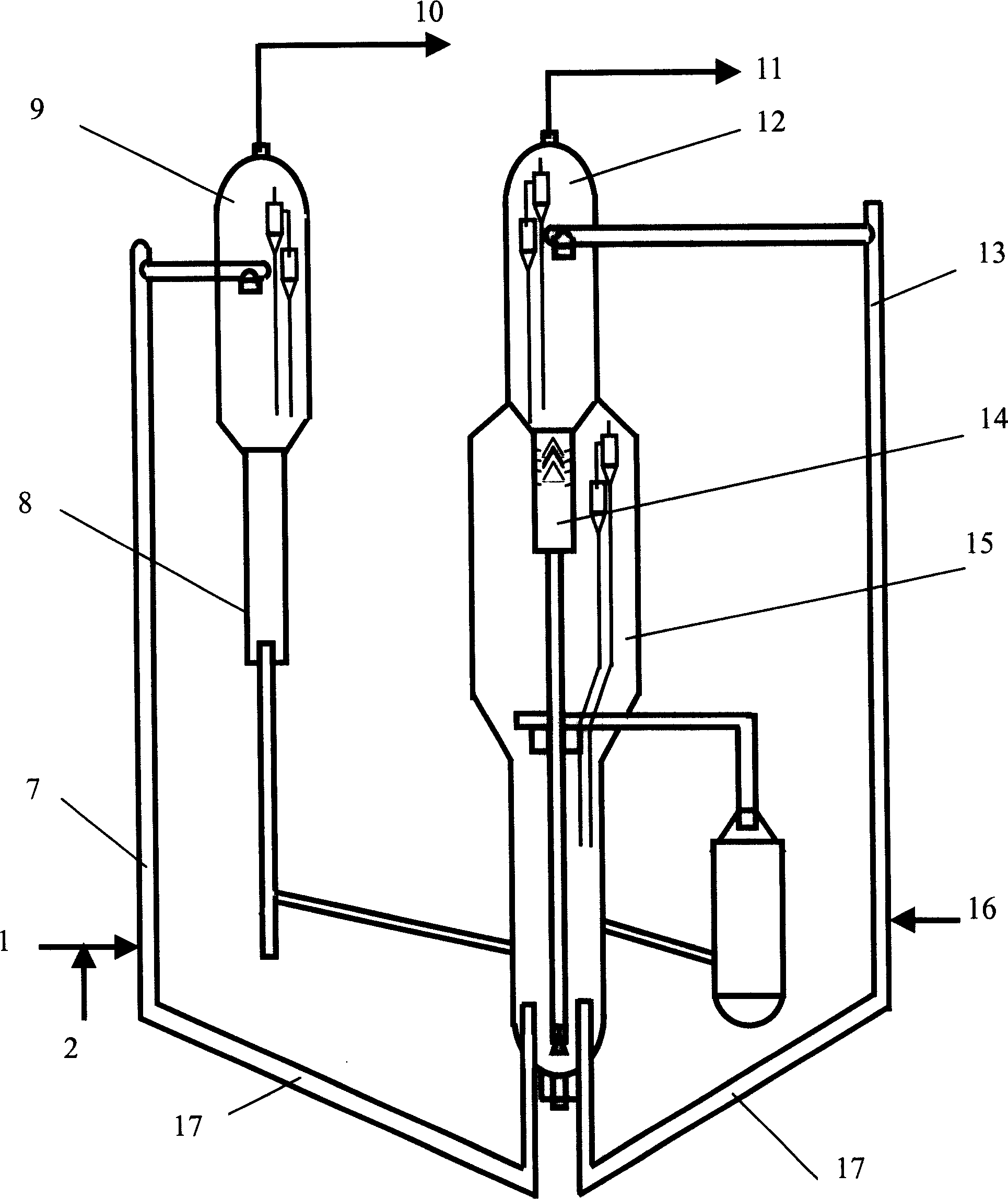

Method used

Image

Examples

Embodiment 1

[0032] This example illustrates: using a fixed bed reactor, using decahydronaphthalene as a hydrogen donor, and using ZnO / Al 2 o 3 As a catalyst, reduce the sulfur content of gasoline.

[0033] In a small fixed-bed reactor with a catalyst loading of 10 grams, decahydronaphthalene is used as a hydrogen donor, and ZnO / Al 2 o 3 As a catalyst, the raw material oil used in the test is FCC gasoline produced by the catalytic cracking unit of Sinopec Luoyang Branch, and its properties are shown in Table 1. The main operating conditions are shown in Table 2. The test procedure is as follows: add 3% decahydronaphthalene to the catalytic cracking gasoline, then contact and react with the catalyst in the fixed bed reactor, and collect the obtained cracked oil gas after three-stage condensation and cooling. Gas and liquid products; cracked gas analyzed by gas chromatography for its composition, C 5 The above components are included in the gasoline fraction; the liquid product is measur...

Embodiment 2

[0035] Same as Example 1, except that no hydrogen donor is added to the FCC gasoline, and the results are listed in Table 2.

[0036] Comparing the two groups of data in Table 2, it can be seen that after the present invention is adopted, the desulfurization rate of gasoline rises from 32.9% to 50.3%. At the same time, the retention rate of gasoline is increased, and the yield of dry gas and liquefied gas is decreased.

Embodiment 3

[0038] This embodiment illustrates: adopt lower reaction temperature, the retention rate of gasoline improves, can not produce gas, and shortcoming is that the octane number of gasoline descends.

[0039] Implementation method is the same as Example 1 and Example 2, except that the reaction temperature is reduced from 380°C to 200°C. The results are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com