Perpendicular magnetic recording medium having alternatively layered structure of Co alloy and Pt thin film, its production method and apparatus

A magnetic recording medium and magnetic recording technology, applied in magnetic recording, data recording, transportation and packaging, etc., can solve the problems of magnetic particles cannot be maintained, saturation recording is difficult, thermal energy resistance is reduced, etc., and achieve excellent particle boundary structure and periodicity Effect of layer structure, improvement of areal recording density, and low SNR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

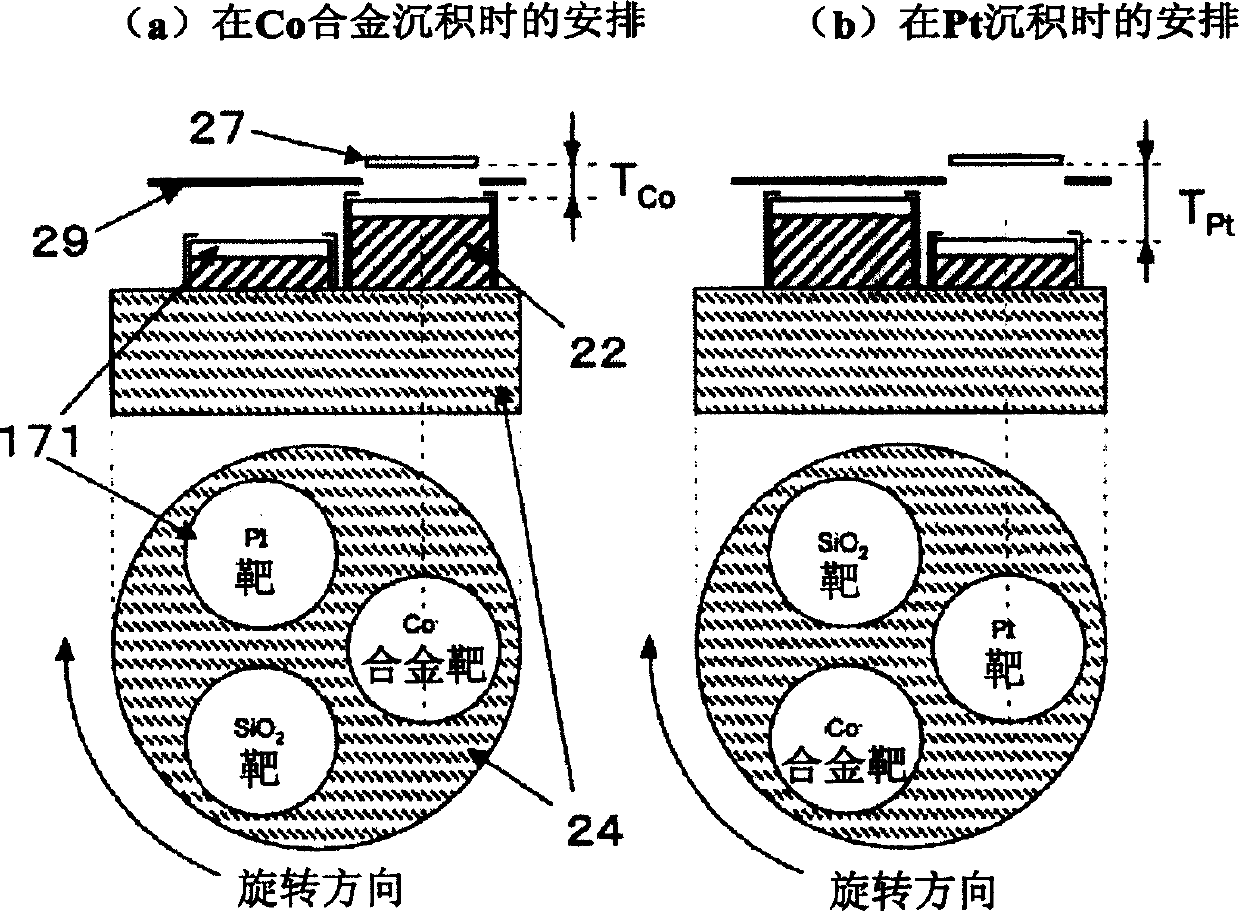

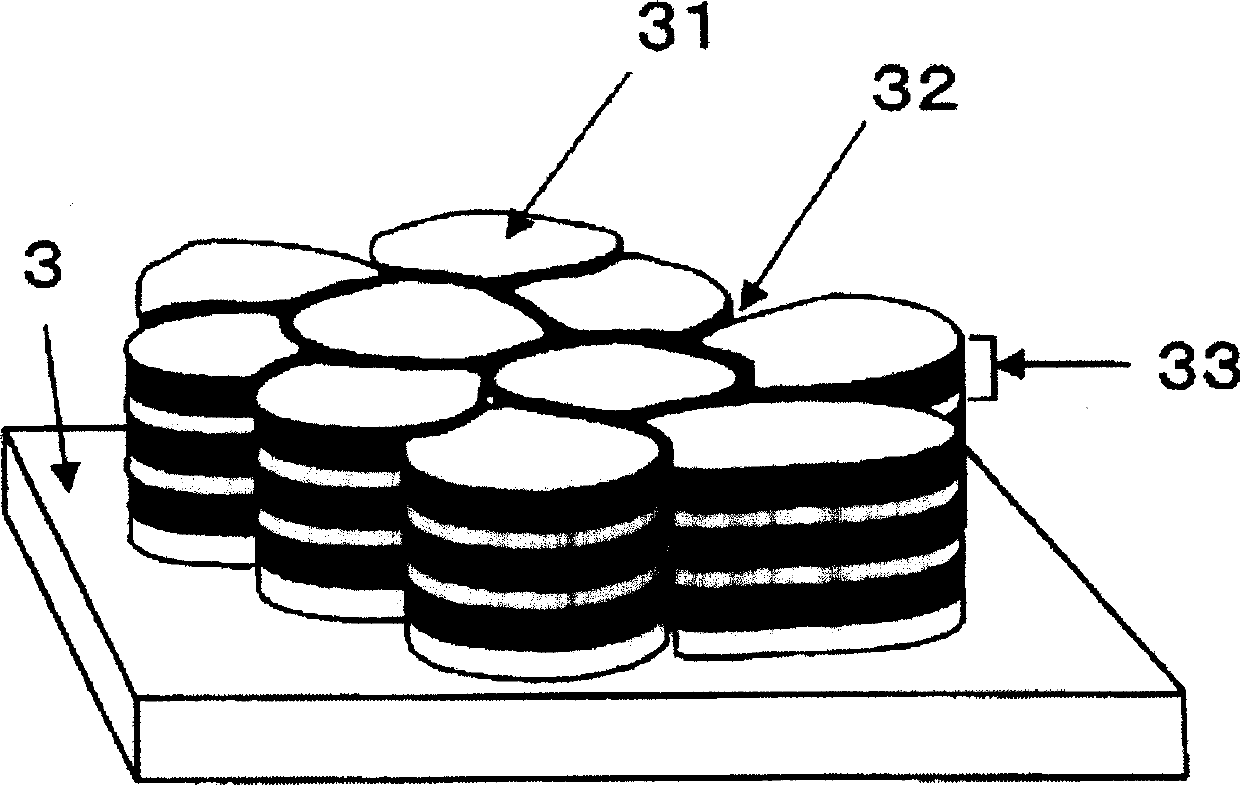

[0067] A first embodiment of the present invention will be described below with reference to some drawings. In this first example, the results of studies on the difference between the granular media of the present invention having a periodic layer structure formed using a multilayer film deposition method and conventional alloy granular media will be specifically described.

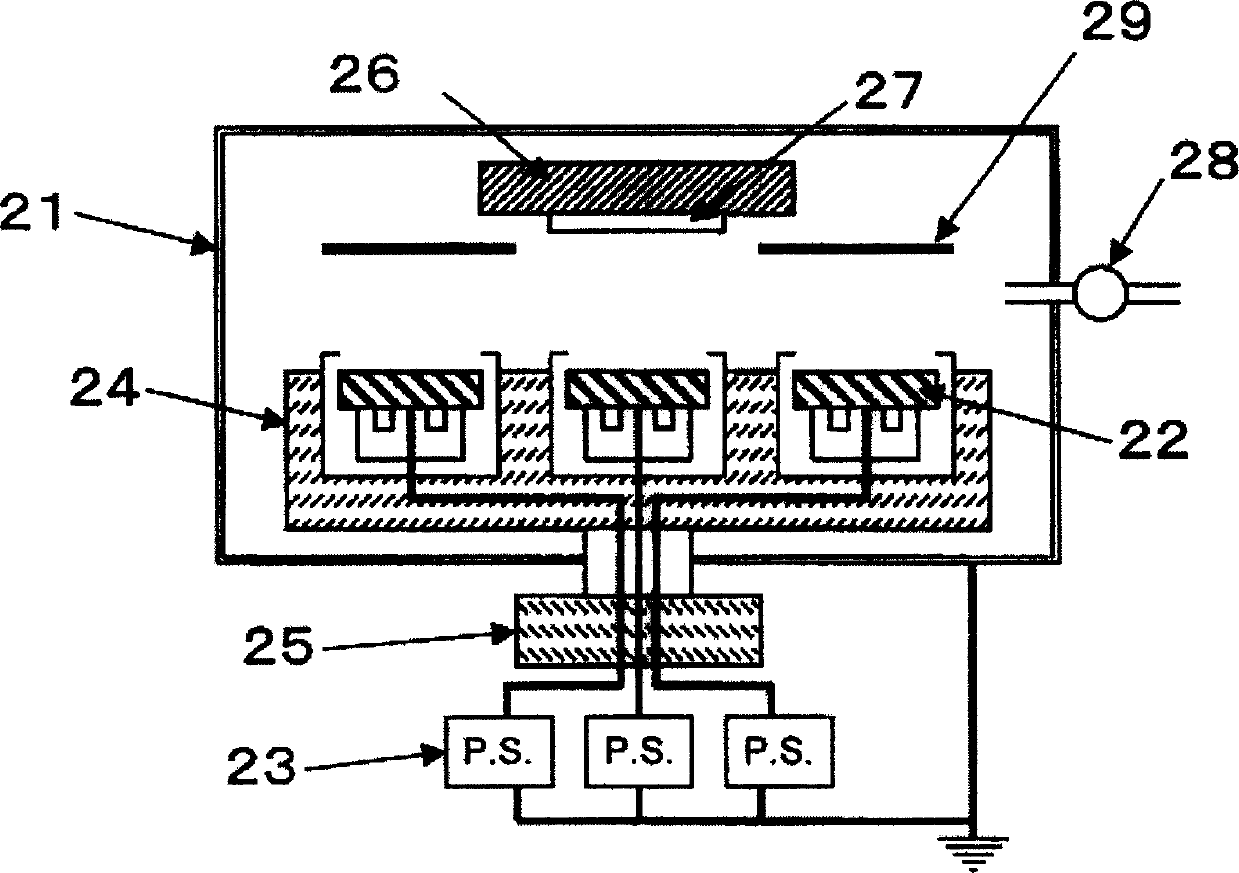

[0068] FIG. 1 shows the structure of a perpendicular recording medium without a soft magnetic underlayer in the first embodiment of the present invention. A nonmagnetic seed film 2 , a nonmagnetic underlayer 3 , a magnetic recording film 4 and a protective layer 5 are sequentially covered on a substrate 1 . These layers and thin films are formed using a sputtering method. Then, the film-deposited substrate 1 is immersed in a lubricant (solution) bath to apply a lubricant coating on the protective layer 5 .

[0069] The base 1 can be made of any material which has some degree of rigidity and heat resista...

no. 2 example

[0101] In this second embodiment, first, measurement results regarding changes in dielectric characteristics when the Pt content in each magnetic metal particle is changed will be described in order to clarify the effects of the present invention. The method for manufacturing the magnetic recording film in this embodiment is the same as that in the first embodiment, and the medium structure is also shown in FIG. 1 . Table 2 lists the deposition conditions of the magnetic recording film 4 in this second embodiment. The sputtering power was varied between the Co alloy layer and the Pt layer to change the Pt content ratio. However, the power was adjusted to determine the lamination period to be about 0.5 nm. The rotation speed of the rotating cathode was determined to be 80 rpm. Also, two sample media were fabricated; SiO was added to one media under optimal conditions (22 vol%) 2 As a granular film without adding SiO to another medium 2 . When fabricated without the additio...

no. 3 example

[0108] In this third embodiment, a comparison result between nonmagnetic metal elements respectively added to the Co alloy layer of the magnetic recording medium of the present invention will be described. The manufacturing method of the magnetic recording medium used in this embodiment is similar to that in the first embodiment, and the composition of the medium is shown in FIG. 1 . A Co alloy is used as the ferromagnetic alloy. Adjust the non-magnetic metal material added into the target (Co alloy layer) and its content ratio. The rotation speed of the rotating cathode was set at 80 rpm. Furthermore, the sputtering power was adjusted so that the Pt content ratio was 22 atomic %, and the stacking period was 0.5 nm.

[0109] FIG. 13 illustrates the results of comparison between the Cr contents added to the Co alloy layer. The amount of Cr added varies from 0% to 20%. And, using SiO 2 to form particle boundaries, and adjust the sputtering power so that the particle boundar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com