Novel process for improved hot carrier injection

An injection effect and carrier technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as poor process pass rate, shortened hot carrier degradation time, and slipping of component electrical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

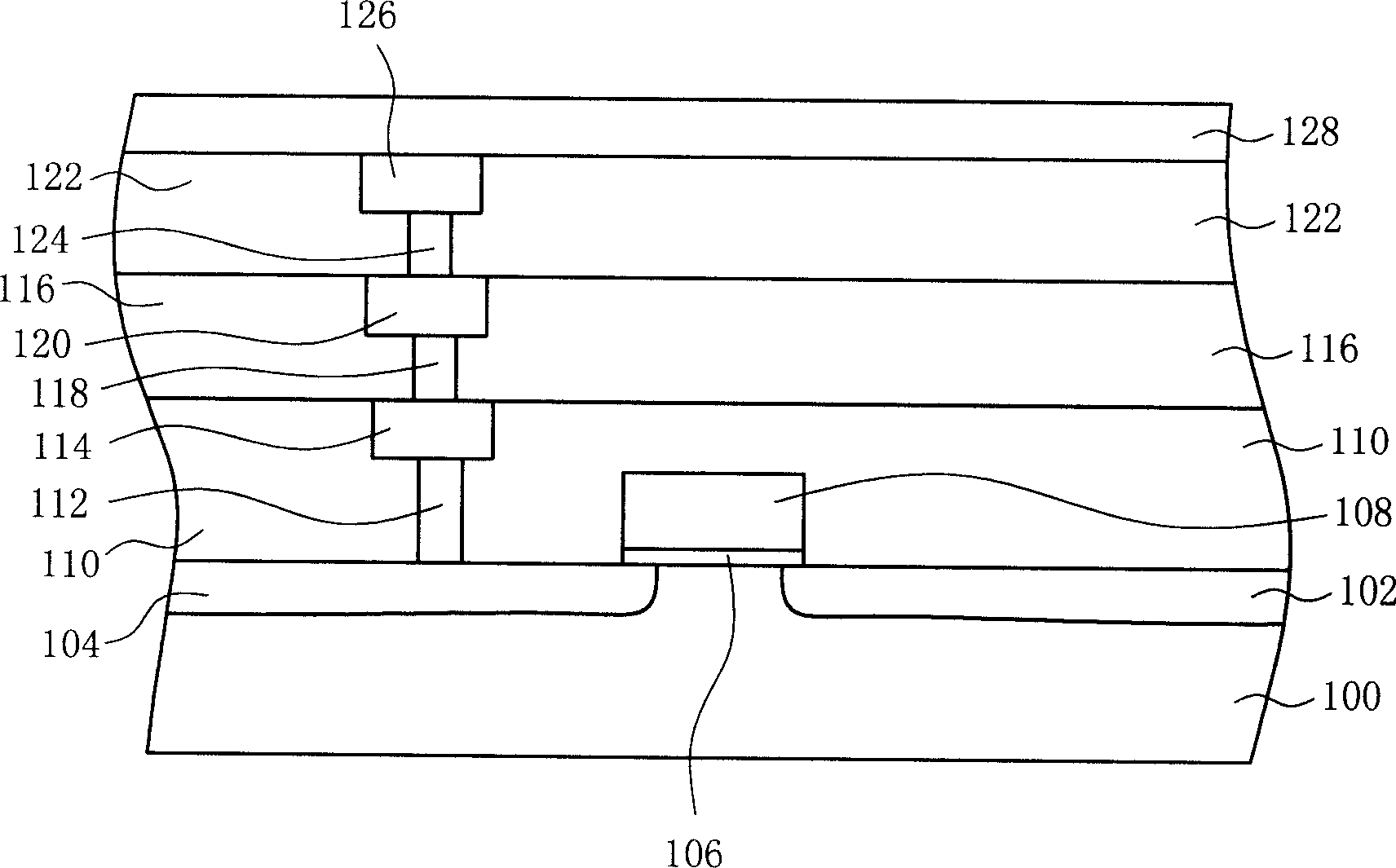

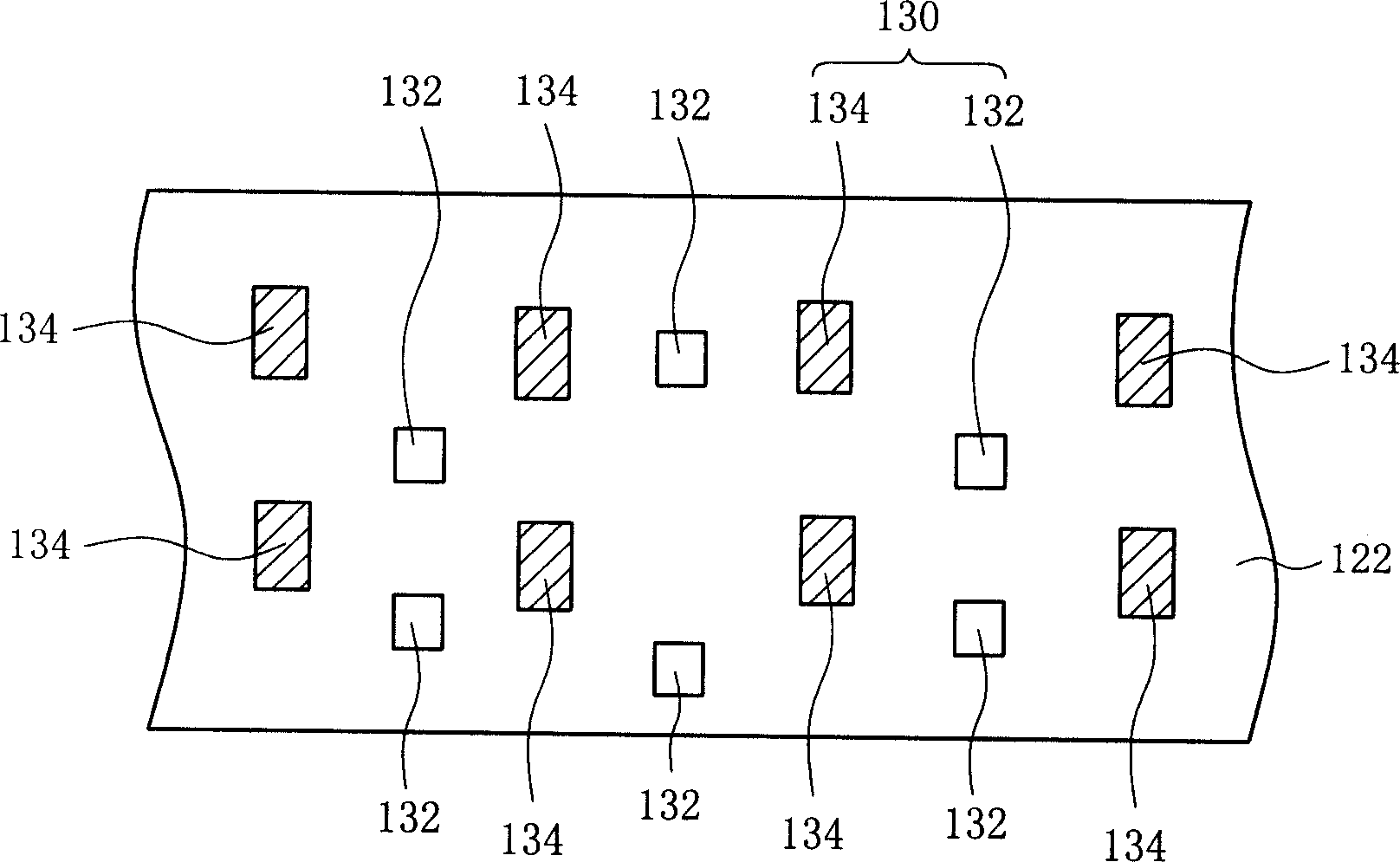

[0043]The invention discloses a method for improving the hot carrier injection effect, and shortens the plasma etching time by increasing the pattern density of the aluminum welding pad. Therefore, the damage of the plasma to the element can be reduced, and the hot carrier injection effect of the element can be improved, thereby achieving the purpose of improving the electrical reliability of the element. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate figure 1 and figure 2 .

[0044] Please refer to figure 1 , figure 1 A cross-sectional view of an element structure according to a preferred embodiment of the present invention is shown. The method for improving the hot carrier injection effect of the present invention firstly provides a semiconductor substrate 100 . A thin gate dielectric layer 106 is then formed on the surface of the substrate 100 by means such as rapid thermal oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com