Mosistureproof and waterproof processing method for wood material deep-processing product

A technology of wood materials and processing methods, which is applied in the field of building decoration materials, can solve the problems of unsatisfactory moisture-proof and waterproof effects and durability, and achieve the effects of significant moisture-proof and waterproof effects, reduced release, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

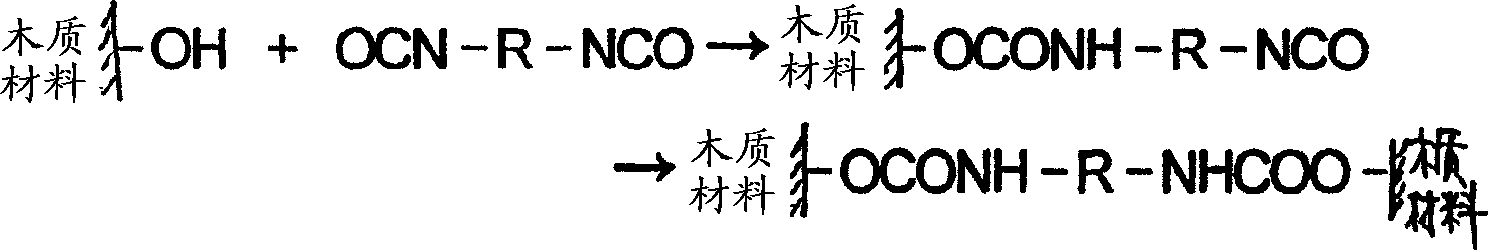

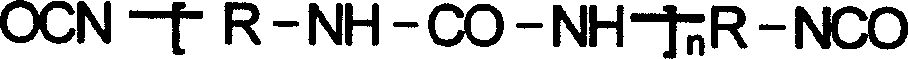

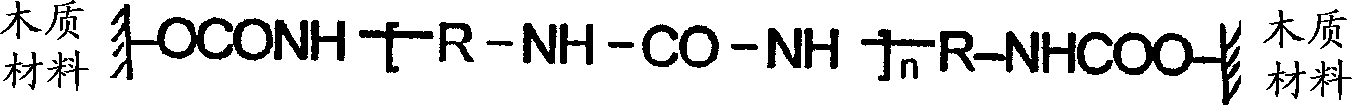

Method used

Image

Examples

Embodiment Construction

[0019] The main process steps of the present invention are as follows: (1) select wooden material as raw material; (2) be processed into the finished product of required shape; (3) apply sealing agent on the specific surface of finished product; (4) described The blocking agent is prepared from diphenylmethane diisocyanate (MDI, 4,4'-diphenylmethane diisocyanate) and solvent.

[0020] The formula of the above sealing agent is: MDI (30%-80%)+solvent (70%-20%). During specific production, oil-soluble dyes or pigments can be added to the above-mentioned sealant to realize coloring while coating.

[0021] The above-mentioned solvents are volatile organic solvents with low toxicity, insoluble in water, good permeability and diffusivity, and no reaction with MDI, such as butanone and the like.

[0022] In practical applications, the above-mentioned finished product may be a reinforced floor, and the exposed substrate surface at the splicing groove of the reinforced floor is coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com