Imvite, polyurethane/imvite nanometer composite material with surface modification and production thereof

A nano-composite material and surface modification technology, applied in the field of polymer nano-composite materials and their preparation, can solve problems such as polyurethane nano-composite materials that have not been seen, and achieve the effect of broadening the application field and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

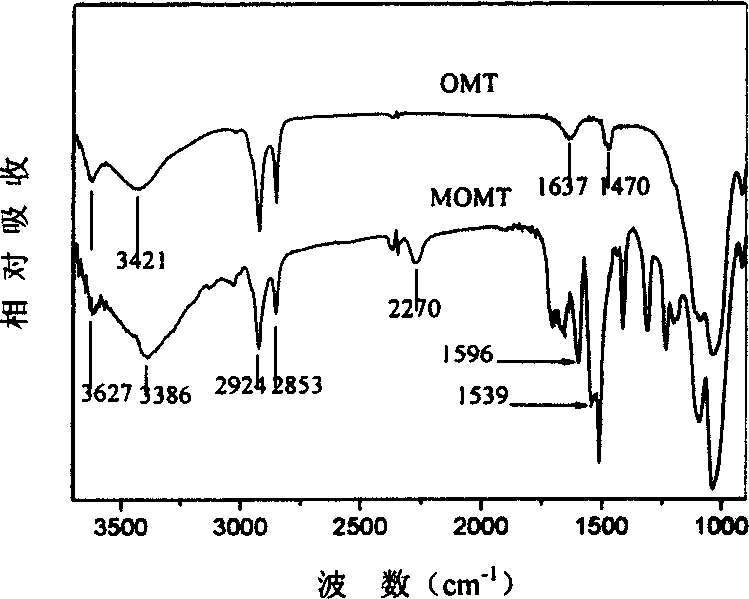

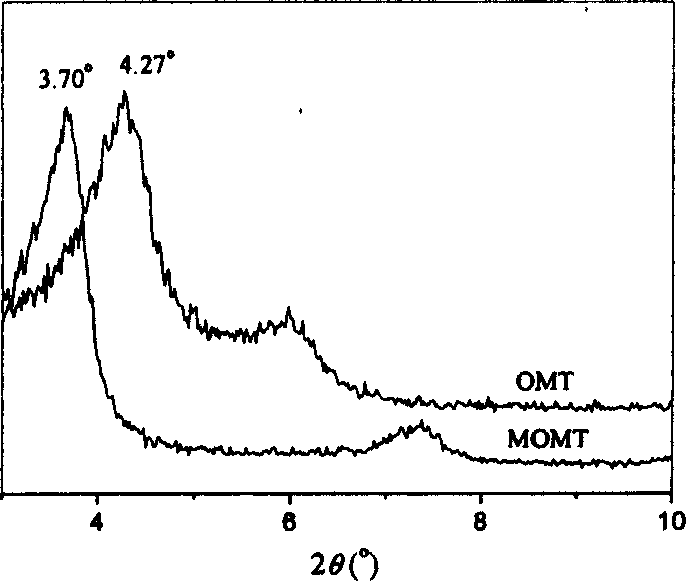

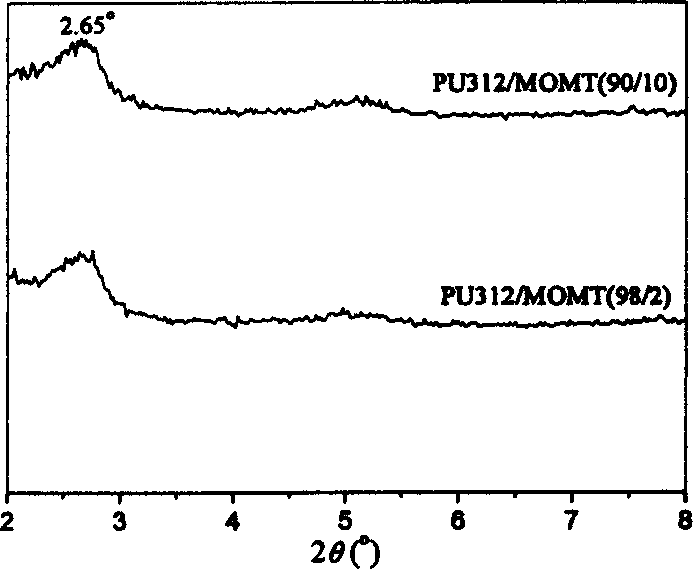

[0026] The surface-modified montmorillonite of the present invention is obtained by modifying the surface hydroxyl groups of organic montmorillonite with diphenylmethane diisocyanate. Its preparation method comprises the following steps:

[0027] 1. Preparation of organic montmorillonite: add 40g montmorillonite and 725ml distilled water into a three-neck flask, stir and heat up to 80°C; add 17.5g cetyltrimethylammonium bromide and 20ml distilled water into a beaker, heat to 80°C; then mix the two and stir for 8 hours; the reaction product is filtered and washed with distilled water until there is no Br - Ions (with 0.1mol / l AgNO 3 Solution test filtrate until no precipitation); vacuum-dried, ground, and passed through a 325-mesh sieve.

[0028] 2. Preparation of surface-modified montmorillonite: Add 16 g of organic montmorillonite and 784 g of toluene prepared in step 1 into a dry four-necked bottle, stir to form a suspension, and then pour dry N 2 protection, add 16g of d...

Embodiment 2

[0030] Another preparation method of surface-modified montmorillonite according to the present invention:

[0031] Add 40g of organic montmorillonite and 760g of toluene prepared in step 1 of Example 1 to the dry four-necked bottle, stir into a suspension and feed into dry N 2 For protection, add 40 g of diphenylmethane diisocyanate and react at 80° C. for 6 hours. The reaction product was suction-filtered under reduced pressure, then extracted with toluene for 24 hours, dried, ground, and passed through a 325-mesh sieve.

Embodiment 3

[0033] Another preparation method of surface-modified montmorillonite according to the present invention:

[0034] Add 64g of organic montmorillonite and 736g of toluene prepared in step 1 of Example 1 to the dry four-necked bottle, stir into a suspension and feed into dry N 2 protection, add 70g of diphenylmethane diisocyanate, and react at 90°C for 12 hours. The reaction product was suction-filtered under reduced pressure, then extracted with toluene for 24 hours, dried, ground, and passed through a 325-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com