Method and apparatus for treating waste water by microwave photocatalysis

A catalytic treatment, microwave light technology, applied in chemical instruments and methods, illumination water/sewage treatment, water/sewage treatment, etc., can solve the problems of shortening the life of electrodeless lamps, long time required for degradation, and low luminous efficiency, etc. To achieve the effect of improving the photocatalytic degradation efficiency, occupying less floor space and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

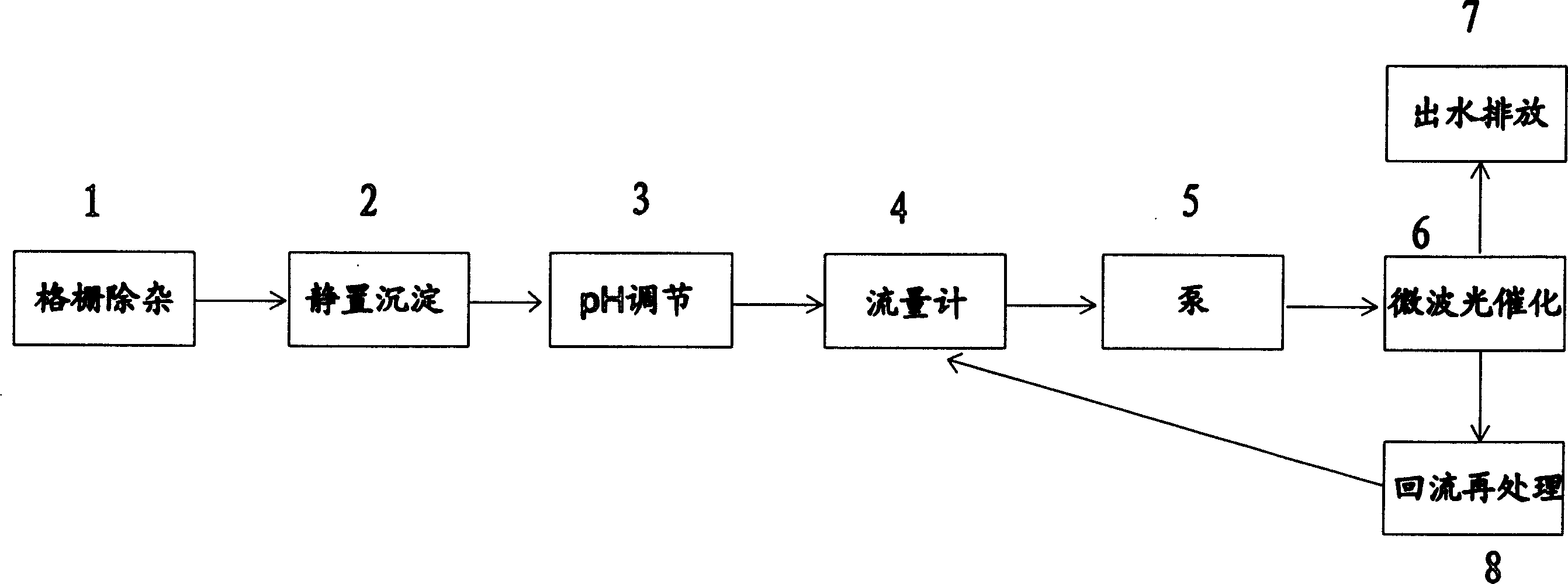

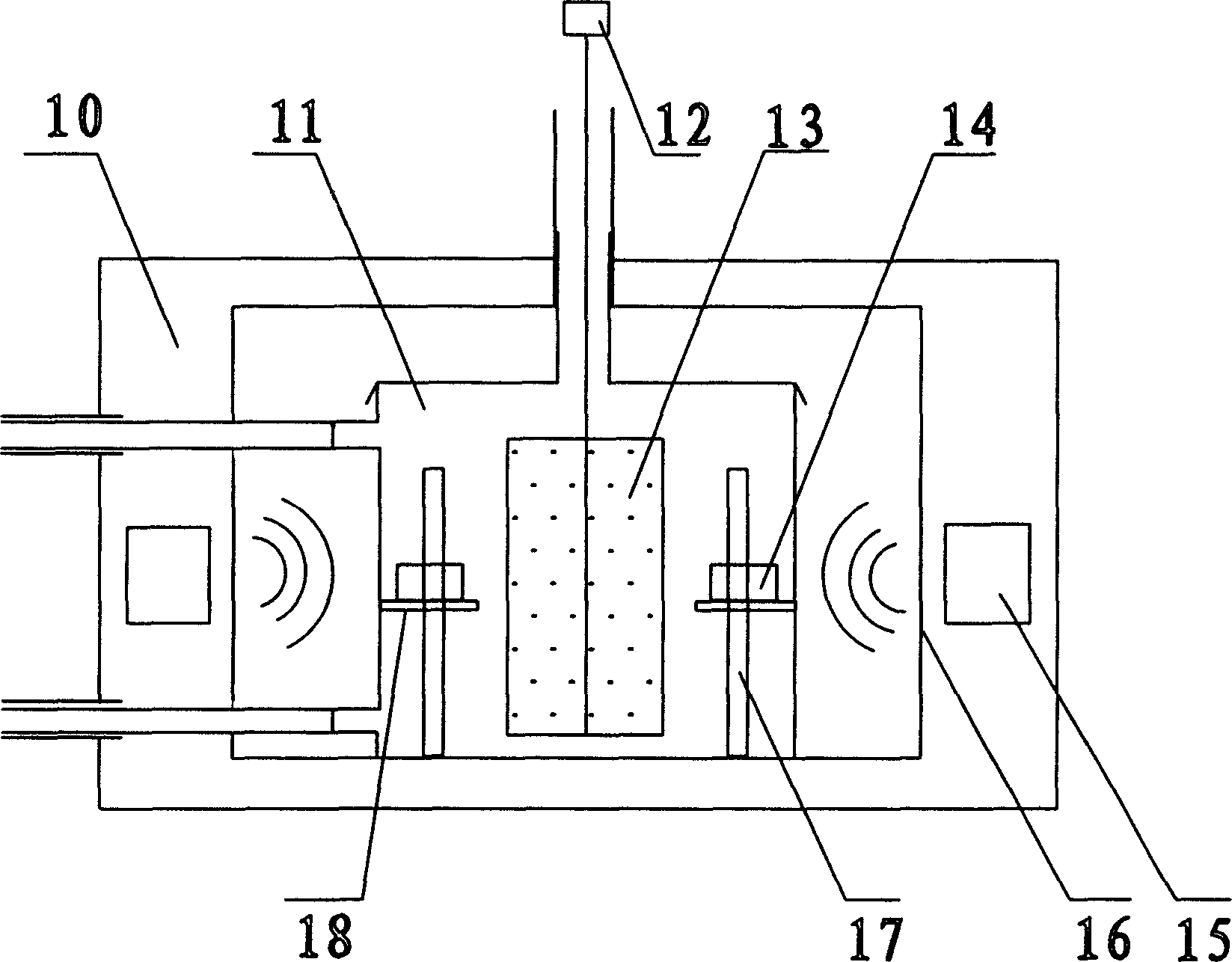

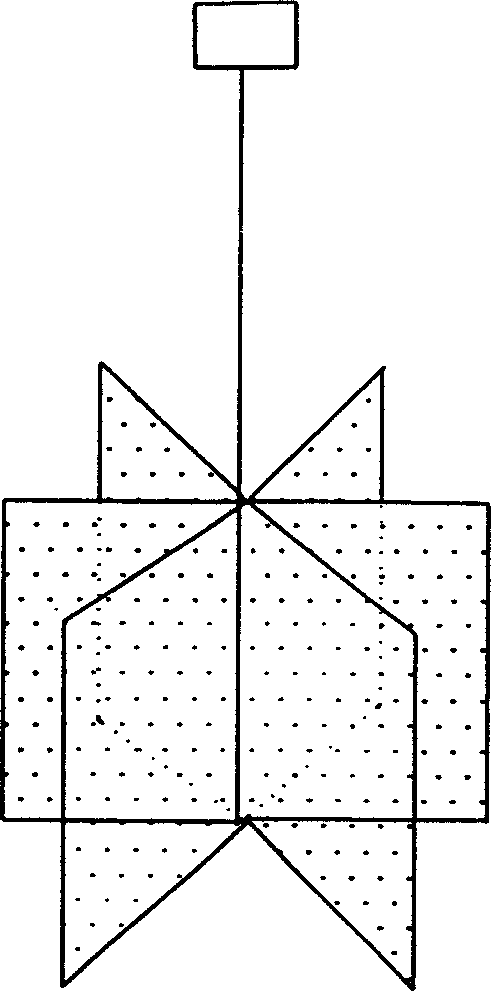

Embodiment 1

[0021] Prepare a 50 mg / L m-nitrophenol aqueous solution to simulate phenol-containing wastewater, without needing a grid to remove impurities. After standing still, adjust the pH of the solution to 3-7. The phenol-containing wastewater passes through the flow meter [4] and the pump [5] at a flow rate of 1.5 L / min Enter the 25L waste water reaction chamber [11], the speed is controlled so that the waste water in the waste water reaction chamber [11] stays for 15 to 20 minutes, and the water flow direction is the way of going in and out. The microwave power is 1000W, and the four electrodeless lamps [17] located in the microwave field are excited by the microwave to generate ultraviolet-visible light, and the TiO loaded on the quartz stirrer [13] by the sol-gel method 2 The nanocatalyst is irradiated by ultraviolet-visible light, and at the same time, the quartz agitator [13] is driven by the motor [12] to rotate at a speed of 30 r / m. At this time, the phenolic wastewater solutio...

Embodiment 2

[0023] Prepare 50mg / L Rhodamine-B aqueous solution to simulate dye wastewater, adjust the pH value to 3-7, and after standing still, enter the 25L wastewater reaction chamber at a flow rate of 1L / min through the flow meter [4] and pump [5] [11 ], the speed is controlled so that the wastewater in the reaction chamber stays for 25 to 30 minutes, and the direction of water flow is in the way of going up and down. The microwave power is 1500W, and the 6 electrodeless lamps [17] placed in the reaction chamber are excited by the microwave to generate ultraviolet-visible light, and the quartz stirrer [13] is loaded with Mn / TiO 2 Catalyst, the doping amount is 0.5%, and the quartz stirrer is driven by an external motor [12] to rotate at a speed of 20r / min. The temperature in the waste water reaction chamber is less than 100°C and normal pressure. The rhodamine-B concentration in the wastewater discharged from the wastewater outlet is less than 10mg / L, and the TOC is reduced by 70%. ...

Embodiment 3

[0025] Prepare a 40mg / L bisphenol A aqueous solution to simulate wastewater containing environmental hormones, adjust the pH to 3-7, and after standing still, enter the 25L wastewater reaction chamber [11] at a flow rate of 1L / min through a flow meter [4] and a pump [5]. Control the waste water in the reaction chamber to stay for 25 to 30 minutes, and the direction of water flow is in the way of going up and down. The microwave power is 1500W, and six electrodeless lamps [17] placed in the reaction chamber are excited by microwaves to generate ultraviolet-visible light. Ni / TiO loaded on the quartz stirrer [13] 2 The catalyst (doping amount 0.5%) was irradiated by ultraviolet-visible light, and at the same time, the quartz stirrer was driven by an external motor [12] to rotate at a speed of 20r / min. The temperature in the waste water reaction chamber is less than 100°C and normal pressure. The concentration of bisphenol A in the wastewater discharged from the wastewater outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com