Method for adding heat to a reactor system used to convert oxygenates to olefins

A compound and olefin technology, applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, carbon compound catalysts, chemical instruments and methods, etc., can solve problems such as the risk of large extinguishment combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

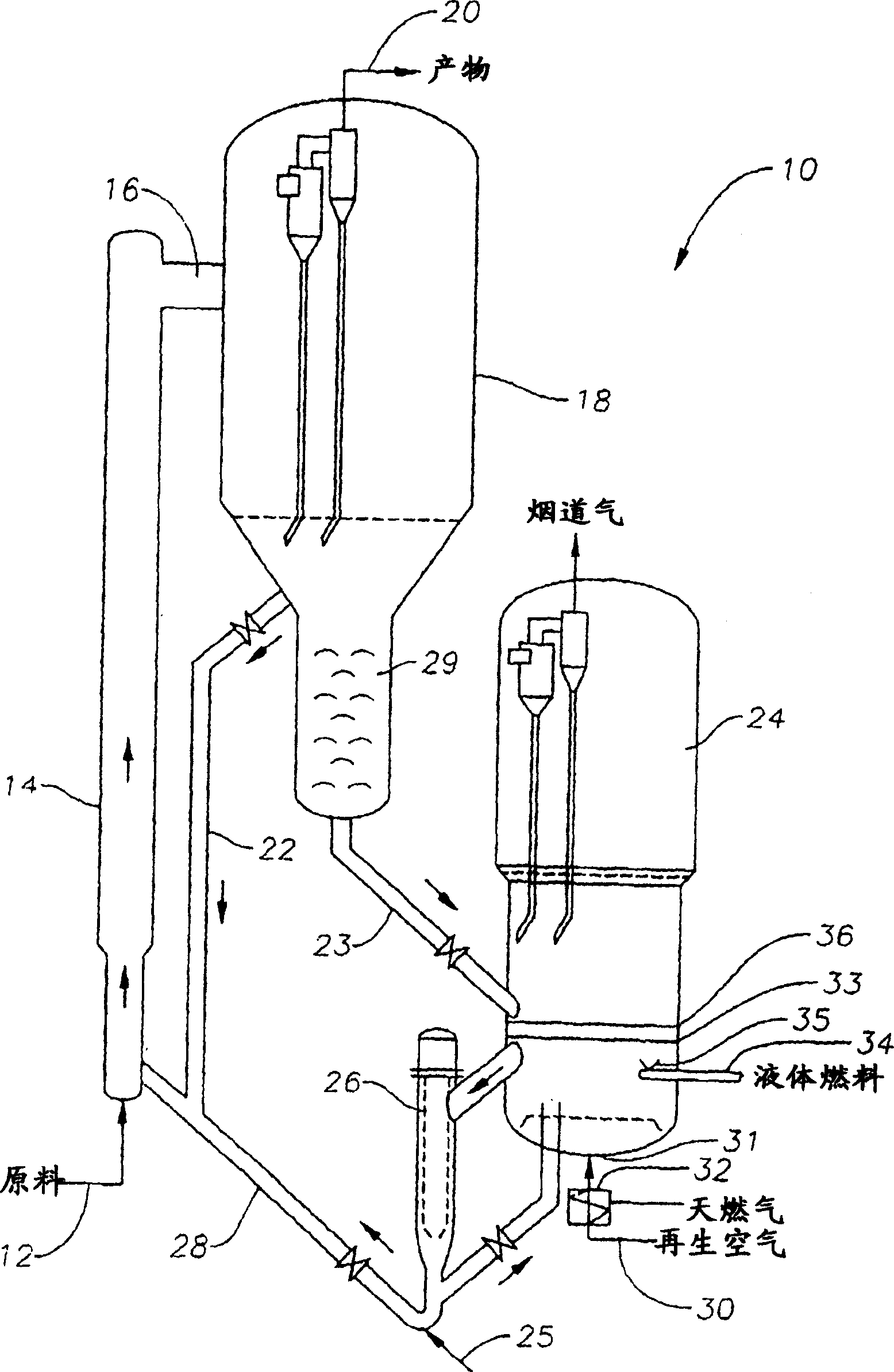

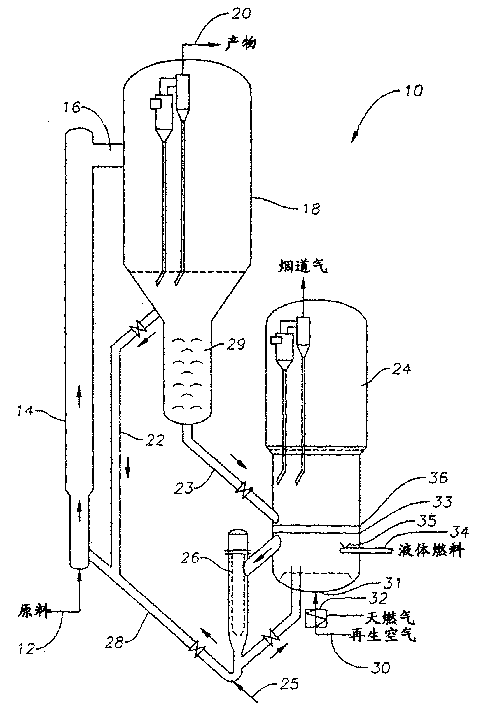

[0061] As noted above, the conversion of oxygenate feedstock to olefins is an exothermic reaction. Once initiated, the reaction is self-sustaining without the addition of external heating. However, there are certain instances where it is necessary to add heat to the above reactor / regenerator system other than that generated by the reaction of the oxygenate feedstock to olefins. Examples include initial drying of refractory linings for reactor and regenerator systems, initial preheating of reactors prior to introduction of oxygenate feedstock, and maintaining reaction temperatures during short-term outages of oxygenate feedstock.

[0062] The process of the present invention achieves this by adding supplemental heat to the regenerator by feeding heating fuel directly into the catalyst fluidized bed. The fluidizing air provides the oxygen for combustion of the heating fuel. The fluidized catalyst particles are well mixed and have sufficient heat capacity to evenly distribute t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com