Preparation method of endogenous particle reinforced aluminium-based composite material

A particle-reinforced aluminum and composite material technology, which is applied in the field of industrial-scale preparation of endogenous particle-reinforced aluminum-based composite materials, can solve the problems of complex preparation process and equipment, high cost, difficult industrial scale production and application, and achieve particle Small size, low cost, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

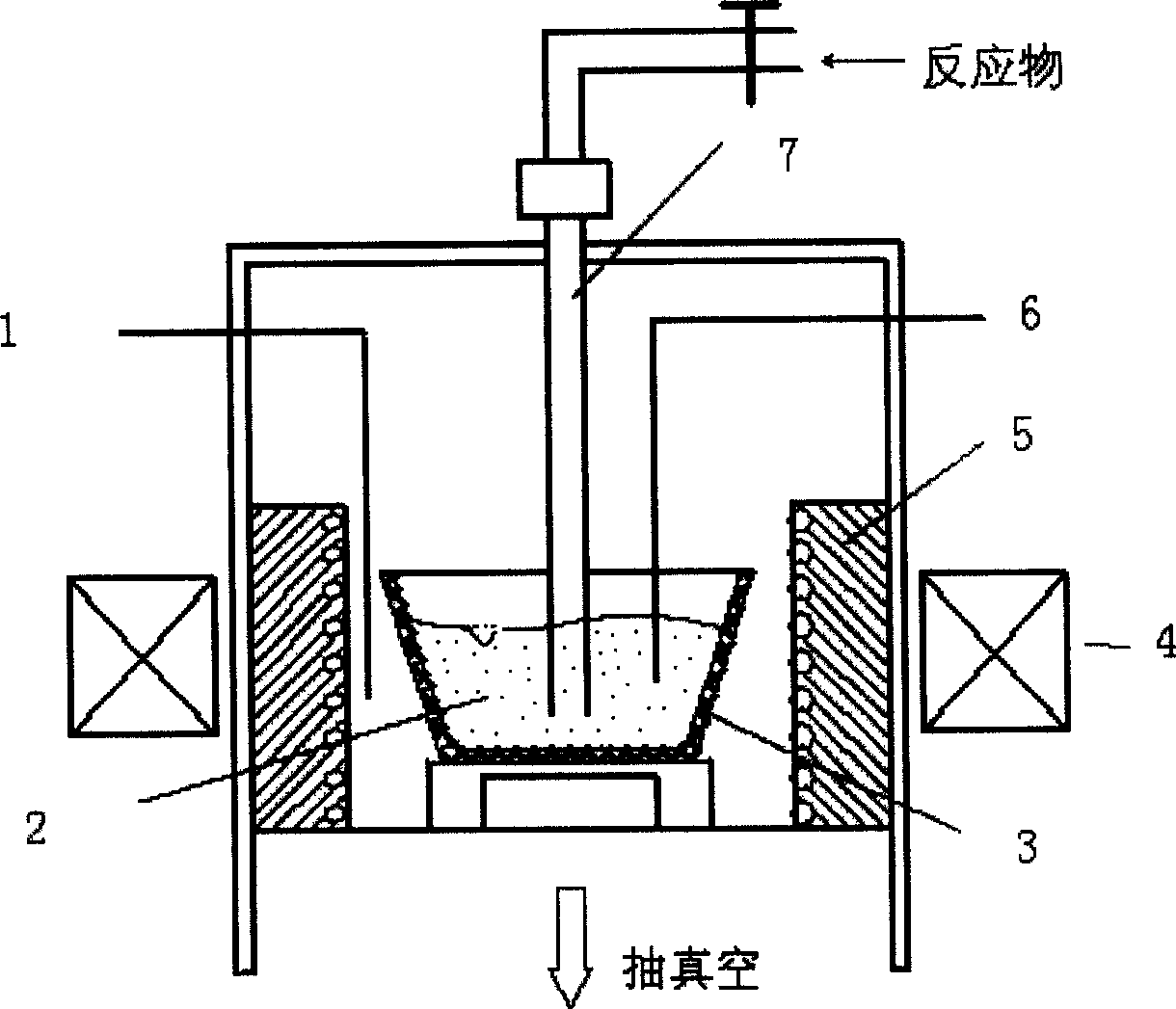

Embodiment 1

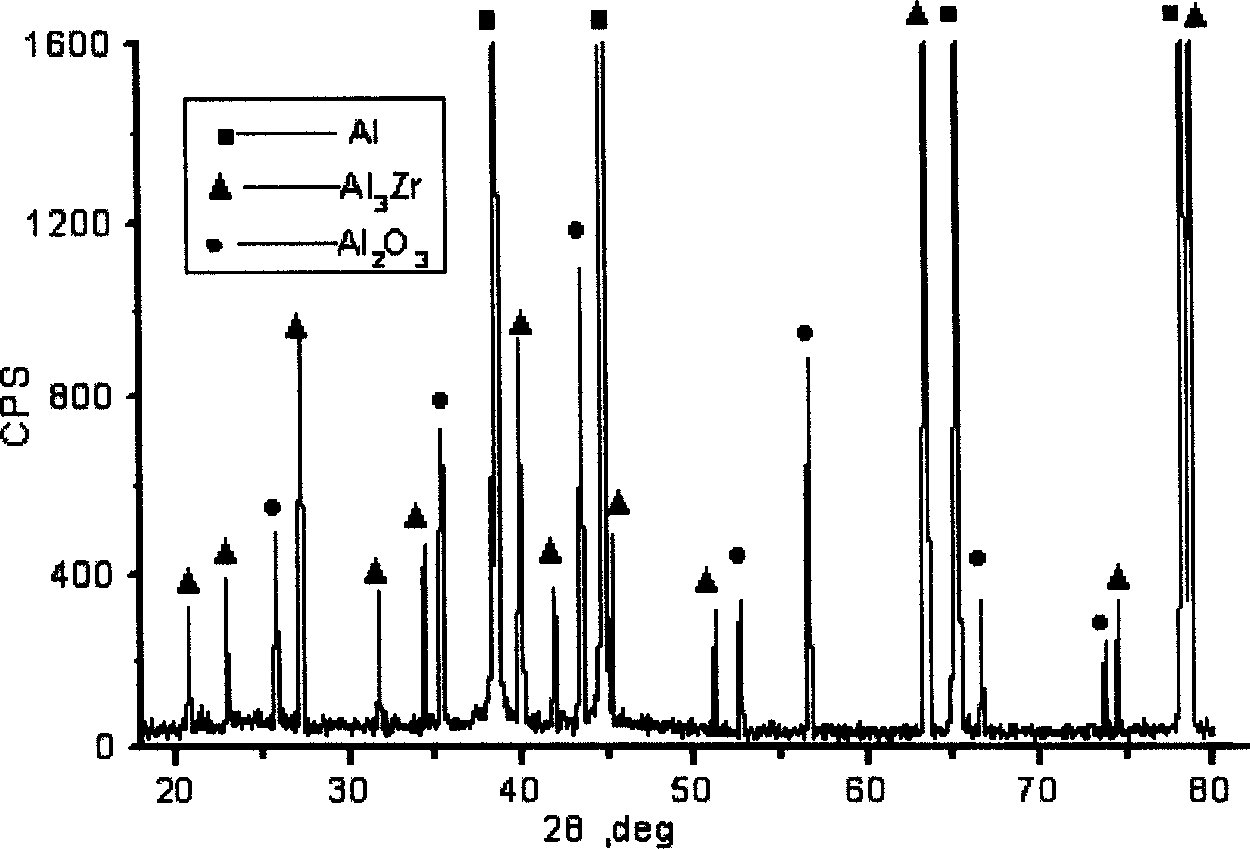

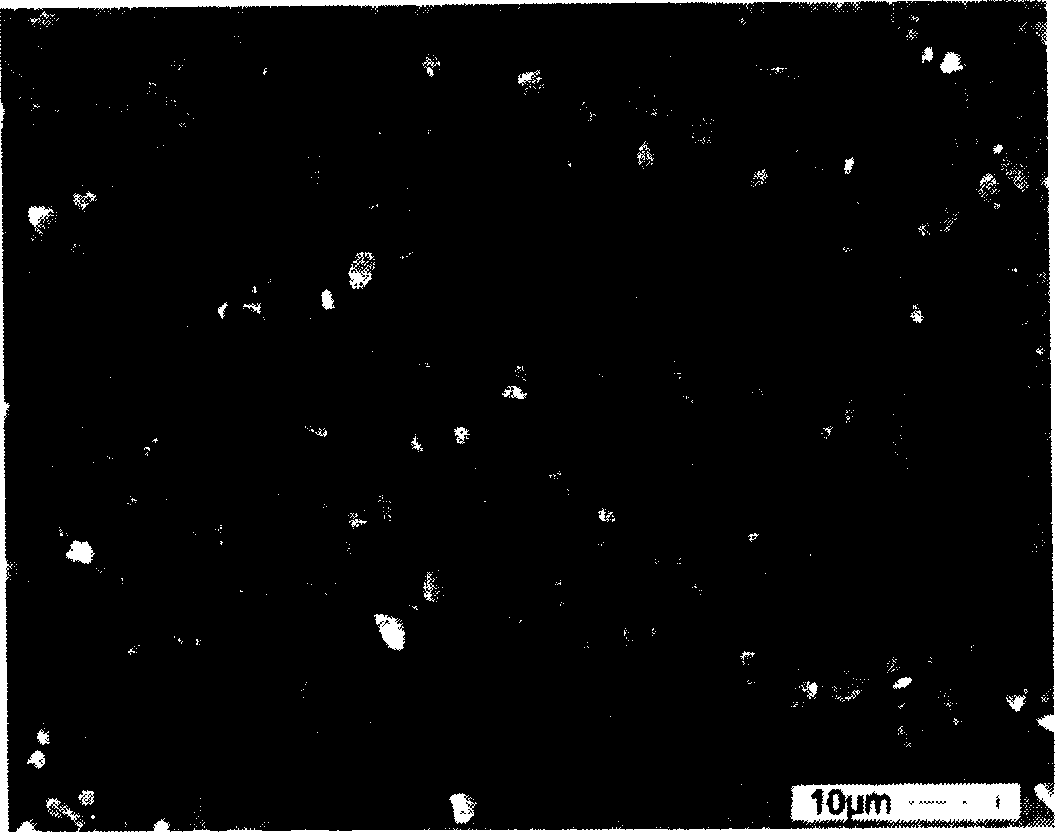

[0034] Example 1: heating resistance furnace (5), melting industrial pure aluminum in ceramic crucible (3), overheating to 950°C for heat preservation, carrying out nitrogen degassing and refining, and after standing for 12min, it will account for 7.6% of the mass percentage of molten aluminum ZrSiO 4 Add the powder into the aluminum melt through the conduit (7), and start electromagnetic stirring with the electromagnetic stirrer (4) at the same time, and keep warm at the same time. The electromagnetic stirring current is 30A, the electromagnetic field frequency is 10Hz, and the stirring time is 40min. Gas refining for 10 minutes, semi-continuous casting at 800°C. The composite material endogenous (Al 3 Zr+Al 2 o 3 ) The theoretical volume fraction of reinforcing particles is 5%. image 3 is the microstructure diagram of the composite material, given by image 3 It can be seen that the generated particles are fine.

Embodiment 2

[0035] Example 2: Heating the resistance furnace (5), melting the A356 alloy in a ceramic crucible (3), overheating to 900 ° C for heat preservation, carrying out nitrogen degassing and refining, and standing for 15 minutes, the mass percentage of the aluminum alloy melt will be 13.1 % powder ZrOCl 2 Add it into the molten aluminum alloy through the conduit (7), and start electromagnetic stirring with the electromagnetic stirrer (4) at the same time, and keep warm at the same time, the electromagnetic stirring current is 40A, the electromagnetic field frequency is 15Hz, and the stirring time is 30min, then remove the slag, and then carry out nitrogen gas Degassing and refining for 12 minutes, then semi-continuous casting at 800°C. The composite material endogenous (Al 3 Zr+Al 2 o 3 ) The theoretical volume fraction of reinforcing particles is 10%. Depend on Figure 4 It can be seen that the generated particles are fine.

Embodiment 3

[0036] Embodiment 3: Heating the resistance furnace (5), melting the A356 alloy in the ceramic crucible (3), overheating to 900 ° C for heat preservation, carrying out nitrogen degassing and refining, and after standing for 15 minutes, it will account for 21.4% of the mass percentage of the matrix alloy liquid mixed powder (K 2 TiF 6 +KBF 4 ) is mixed evenly by the molar ratio of Ti: B=1: 2 and added in the aluminum alloy melt through the conduit (7), and simultaneously starts to carry out electromagnetic stirring with the electromagnetic stirrer (4), carries out heat preservation simultaneously, electromagnetic stirring current 50A, electromagnetic field The frequency is 20Hz, the stirring time is 25min, and then the slag is removed, and the nitrogen degassing refining is carried out for 15min, and the semi-continuous casting is carried out at 800°C. The composite endogenous (TiB 2 +Al 3 The theoretical volume fraction of Ti) reinforcing particles is 15%. Depend on Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com