Hydrogen production method and apparatus and engine employing hydrogen production apparatus

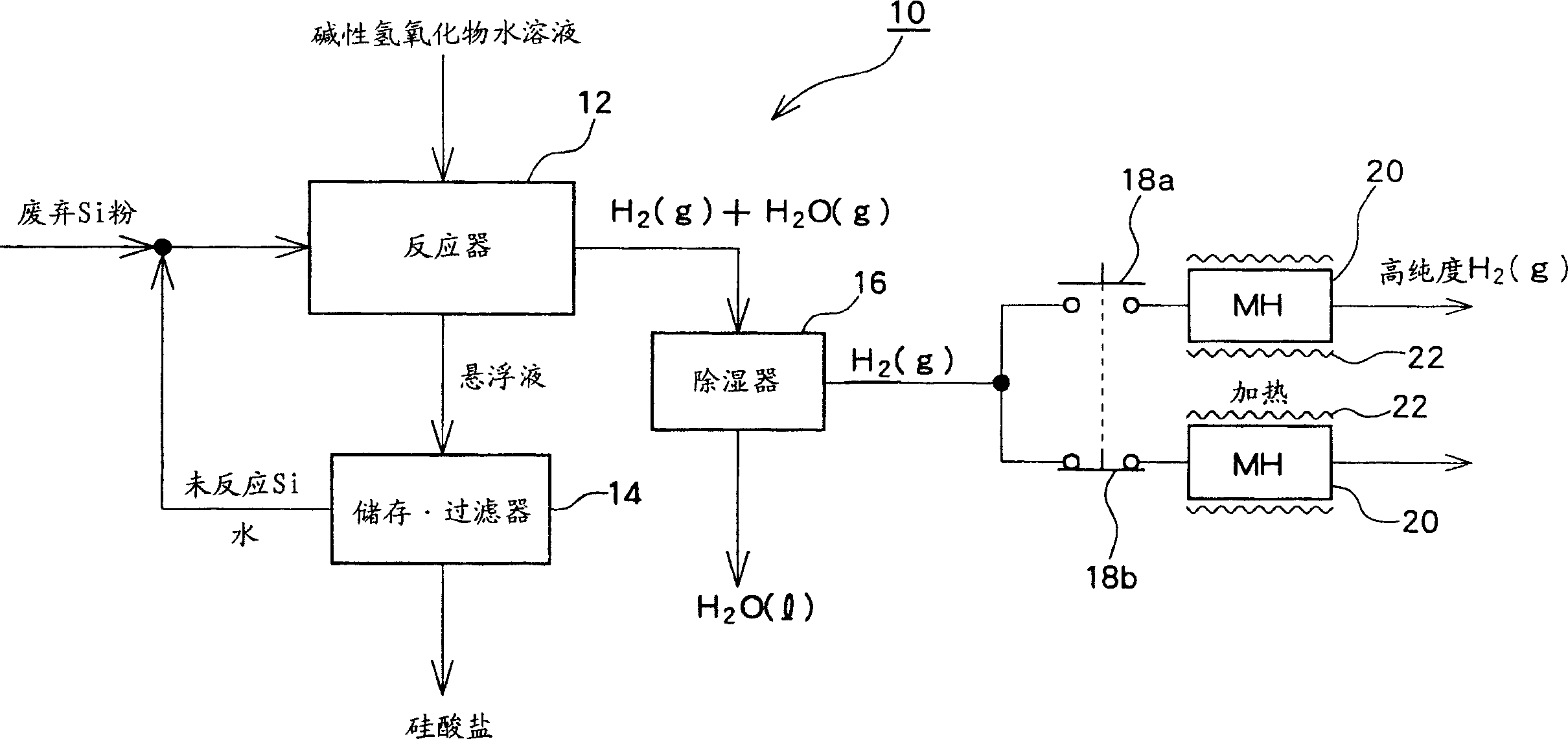

A manufacturing method and a technology for manufacturing devices, which are applied in the production of hydrogen, chemical instruments and methods, hydrogen, etc., can solve the problems of low product qualification rate, and achieve the effects of reducing fuel costs and simplifying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

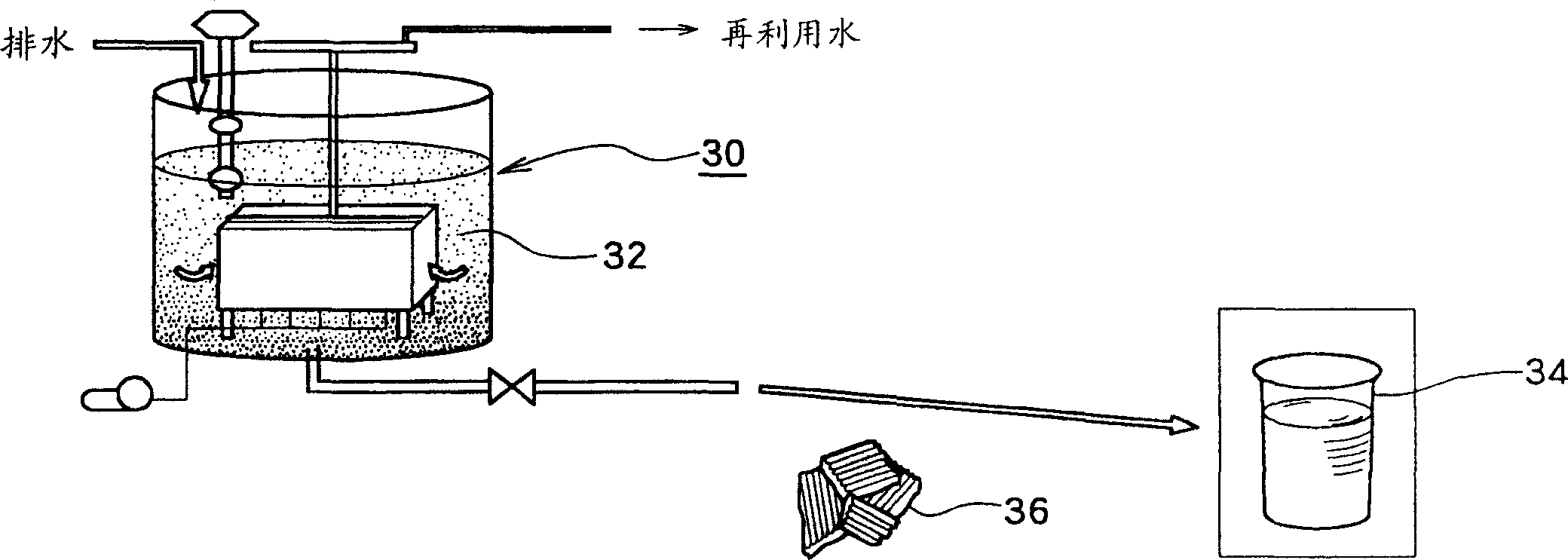

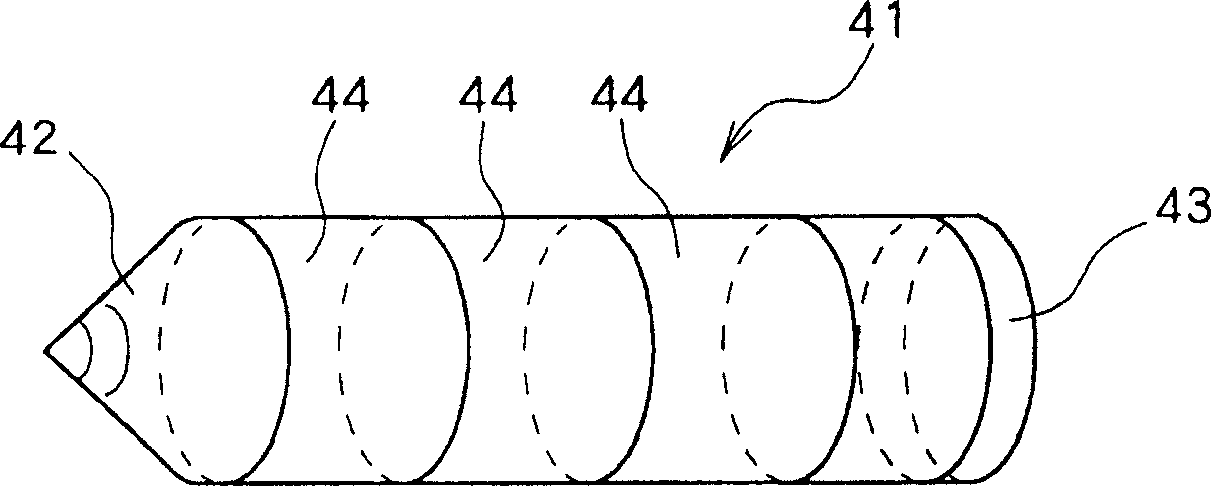

Examples

Embodiment

[0109] The experimental example of using waste silicon to generate high-pressure hydrogen is shown below. Also, in this experiment, a pressure-resistant reaction vessel with an internal volume of 1 liter was used, and the safety valve was set at 17 MPa in consideration of safety. Therefore, only high-pressure hydrogen near 17 MPa was generated. However, if the stoichiometric amount is supplied in this way, It can be inferred that, for example, about 100 MPa is also sufficient.

[0110] In addition, in Experiment Nos. 102 and 103 shown in Table 1, the temperature of the reactor exceeded 50° C. in about 10 seconds without heating equipment, and a high pressure of about 17 MPa was reached by the explosive reaction at this time.

[0111] Experiment number

sample

(purity, quantity)

NaOH aqueous solution (concentrated

degree, volume, initial temperature)

Maximum reach pressure

101

Waste silicon (purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com