Epoxy resin composition for semiconductor encapsulation and semiconductor device using the same

A technology of epoxy resin and semiconductor, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve separation problems, achieve the effects of preventing separation and cracking, high reliability, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13 and comparative example 1-5

[0111] The components shown in Tables 1 and 2 were mixed together in the proportions shown in the table. The mixture was heated (1 minute) at 80° C. using a mixing roll kneader, and thereby melt-kneaded. Subsequently, the melt was cooled, pulverized, and then tabletted. A target epoxy resin composition for semiconductor encapsulation was thus obtained.

[0112] Table 1

[0113] Example

[0114] Table 2

[0115] Example

[0116] Quartz powder in the whole

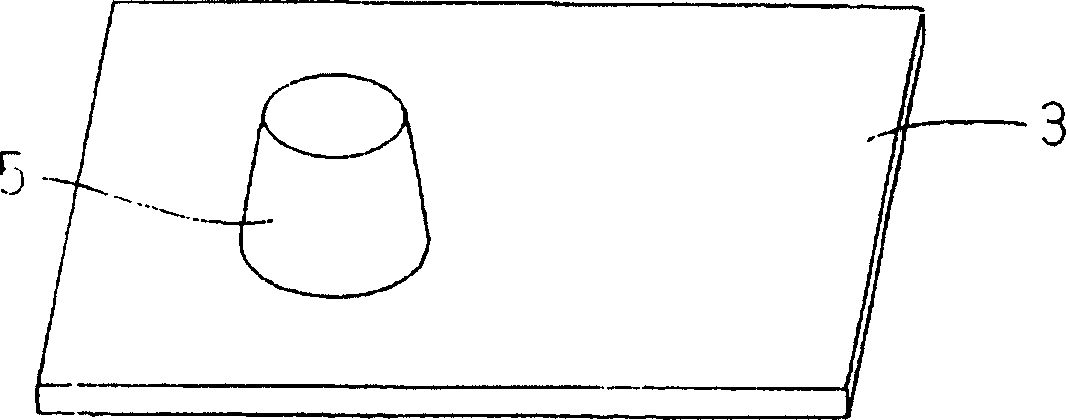

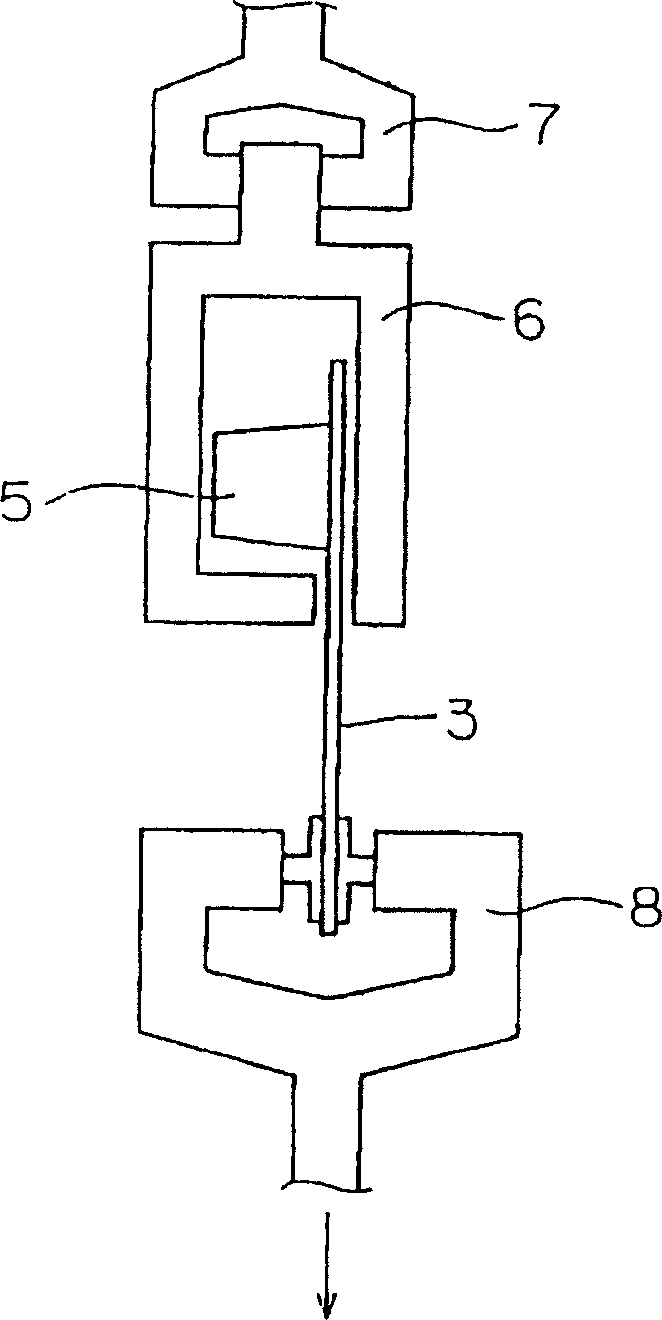

[0117] The adhesiveness and frame separation during molding of the epoxy resin compositions thus obtained in Examples and Comparative Examples were examined / evaluated. The results are shown in Tables 3 and 4.

[0118] adhesiveness

[0119] Each epoxy composition and metal frame plate was used to mold samples for adhesion testing by transfer molding (175°C x 2 minutes and 175°C x 5 hours for post-cure). Such as figure 1 As shown, this sample includes a metal frame plate 3 and a frustum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com