Acoustic surface-wave oscillator system for gas sensor

A gas sensor, surface acoustic wave technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of temperature drift, poor substrate temperature stability, increase system power consumption, etc., to improve frequency stability, reduce insertion loss, Effect of Power Consumption Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] For a fuller understanding of the invention, with additional objects and advantages thereof, reference should now be made to the following detailed description of the invention taken in conjunction with the accompanying drawings.

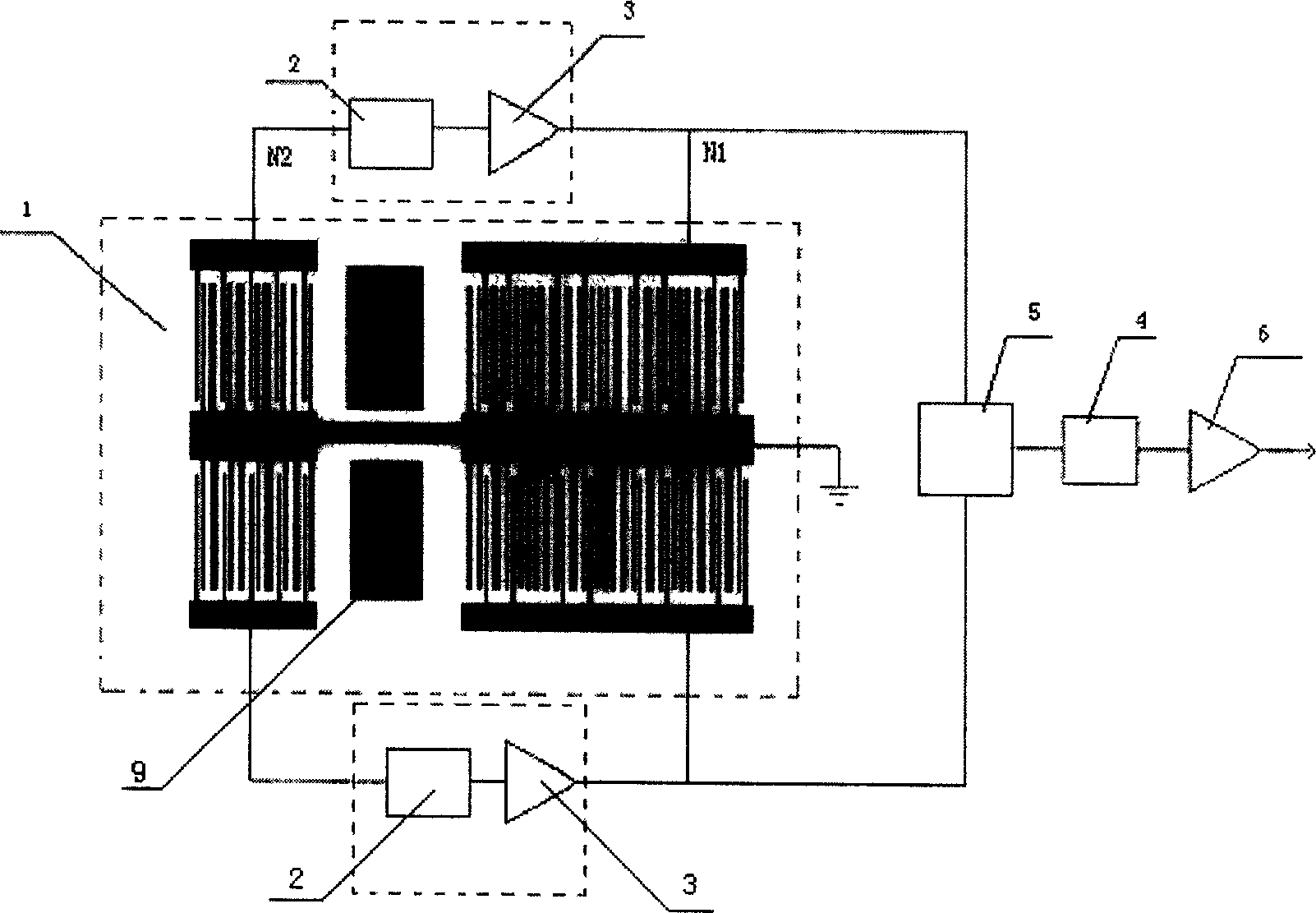

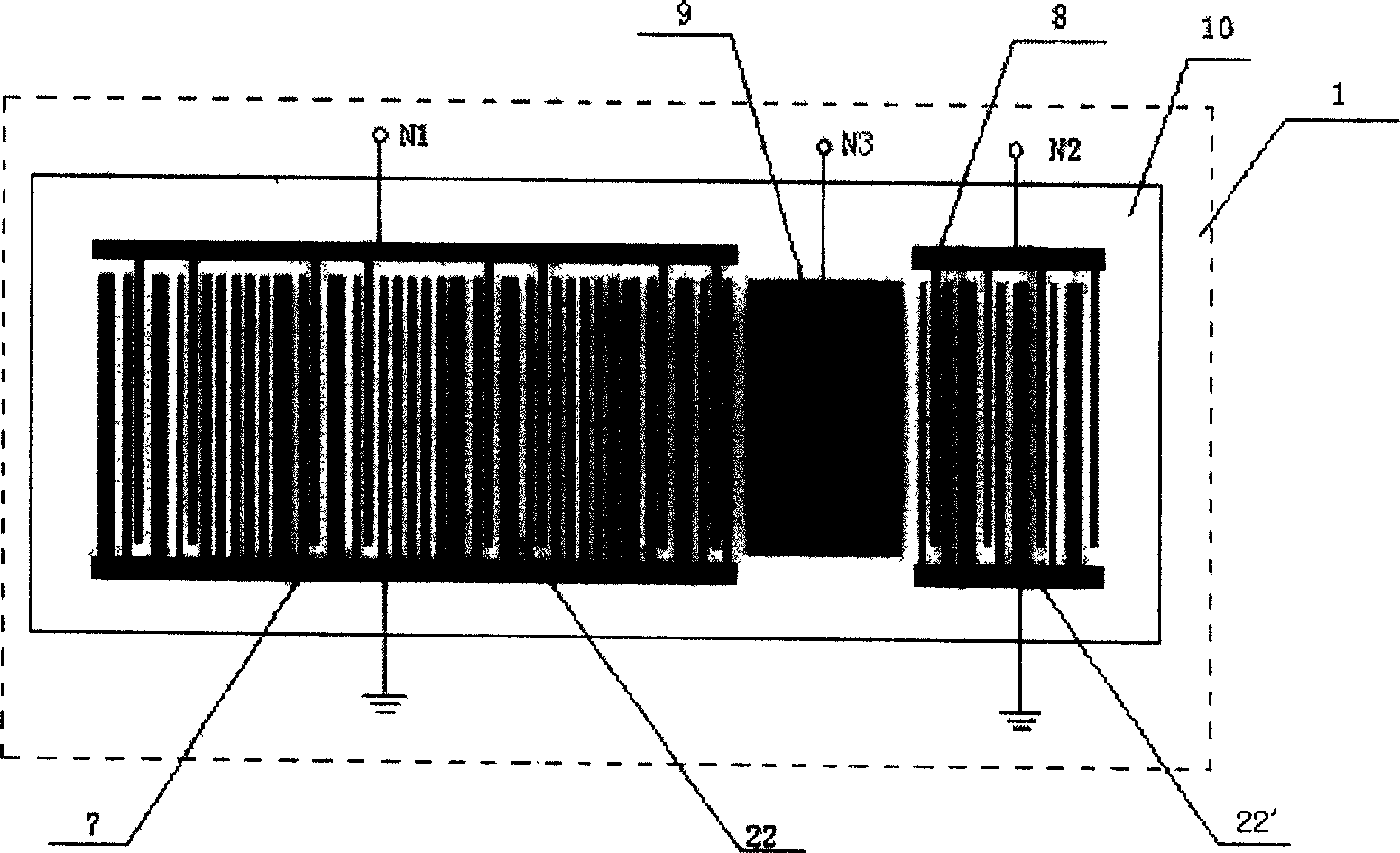

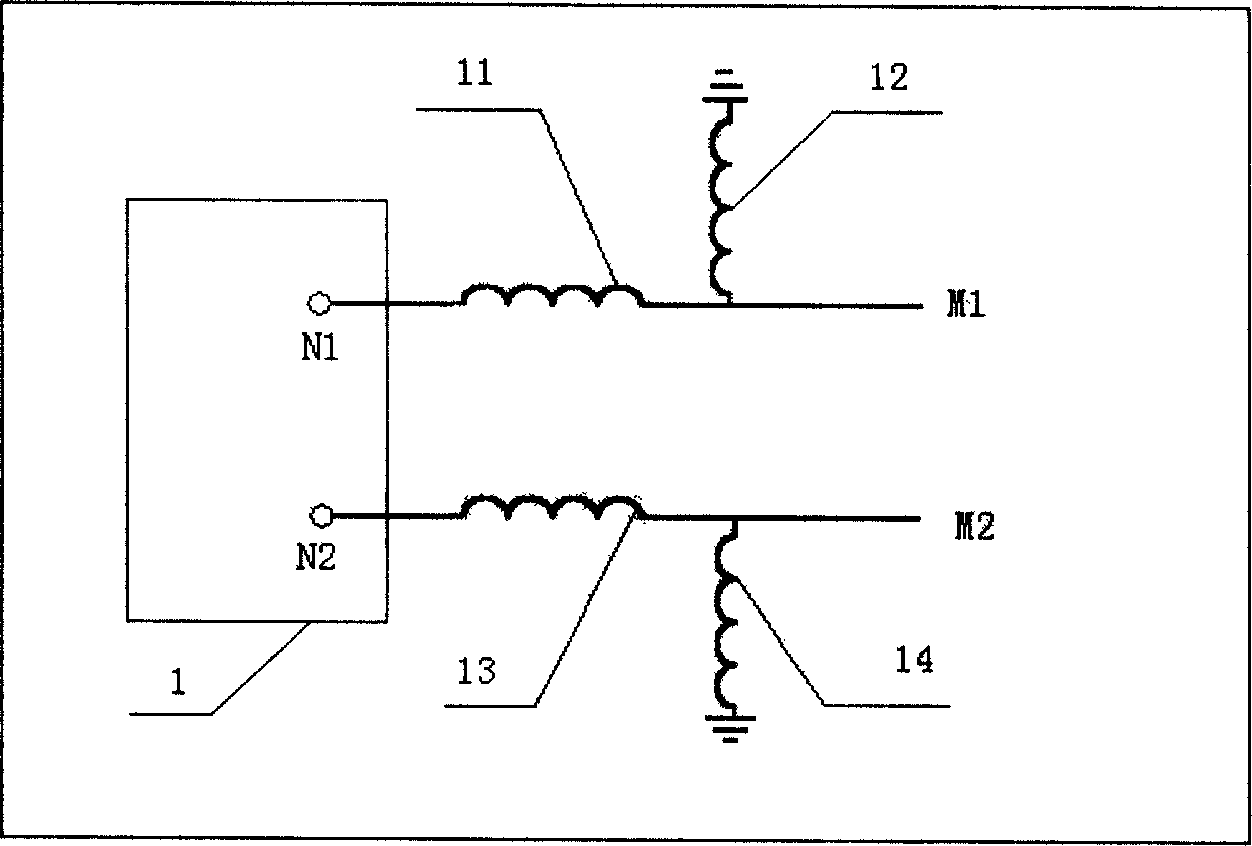

[0042] refer to figure 1 , making a surface acoustic wave oscillator system applied to gas sensors, by figure 1 It can be seen that the oscillator system consists of two sets of SAW oscillators, a set of conventional mixers 5, a conventional low-frequency amplifier 6 and a general low-pass filter 4, and each set of SAW oscillators consists of a A surface acoustic wave delay line 1, a conventional radio frequency amplifier 3, and a phase shifting network 2 are formed. Delay line 1 acts as the feedback element for the overall oscillator. Two sets of delay lines are fabricated on the same substrate. Depend on figure 1 The workflow of the surface acoustic wave oscillator applied to the gas sensor according to the scheme of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com