Process for synthesizing dicreatine malic acid

A technology of dicreatine malate and creatine hydrochloride, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as difficulty in guaranteeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is a kind of method for synthesizing dicreatine malic acid, it adopts the salt exchange method to synthesize dicreatine malic acid, and its process step is carried out in three steps:

[0015] first step,

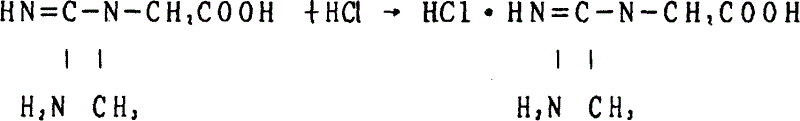

[0016] a) neutralize creatine with hydrochloric acid or sulfuric acid to generate creatine hydrochloride / creatine sulfate,

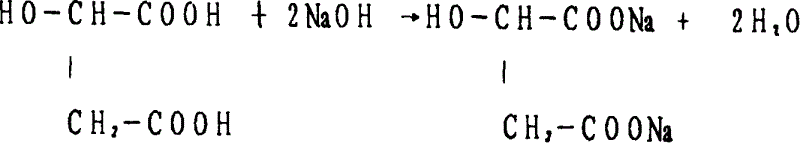

[0017] b) neutralizing malic acid with sodium hydroxide or calcium hydroxide to generate sodium malate / calcium malate;

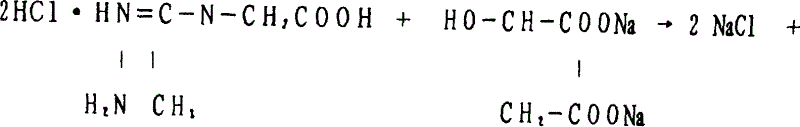

[0018] The second step is to exchange creatine hydrochloride / creatine sulfate with sodium malate / calcium malate to generate dicreatine malate and sodium chloride / calcium chloride or sodium sulfate / calcium sulfate;

[0019] The third step is to use osmotic membrane technology to separate the contained inorganic salt sodium chloride / calcium chloride (sodium sulfate / calcium can be directly filtered and separated), and the filtrate obtained is concentrated and dehydrated, and dried to obtain the finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com