Magnetic material of containing praseodymium

A magnetic material and soft magnetic phase technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of difficult to obtain, difficult to obtain neodymium, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

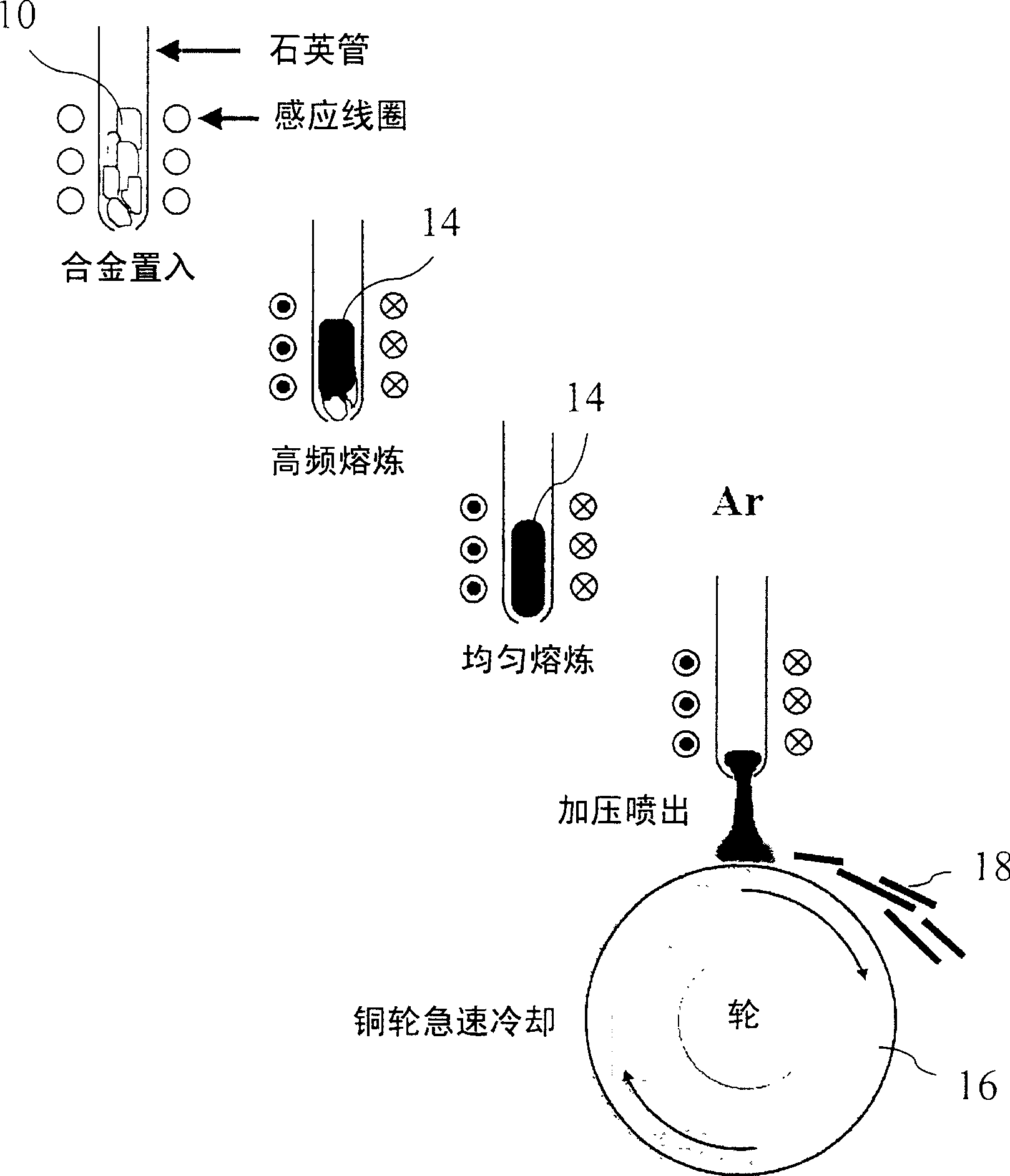

Method used

Image

Examples

Embodiment Construction

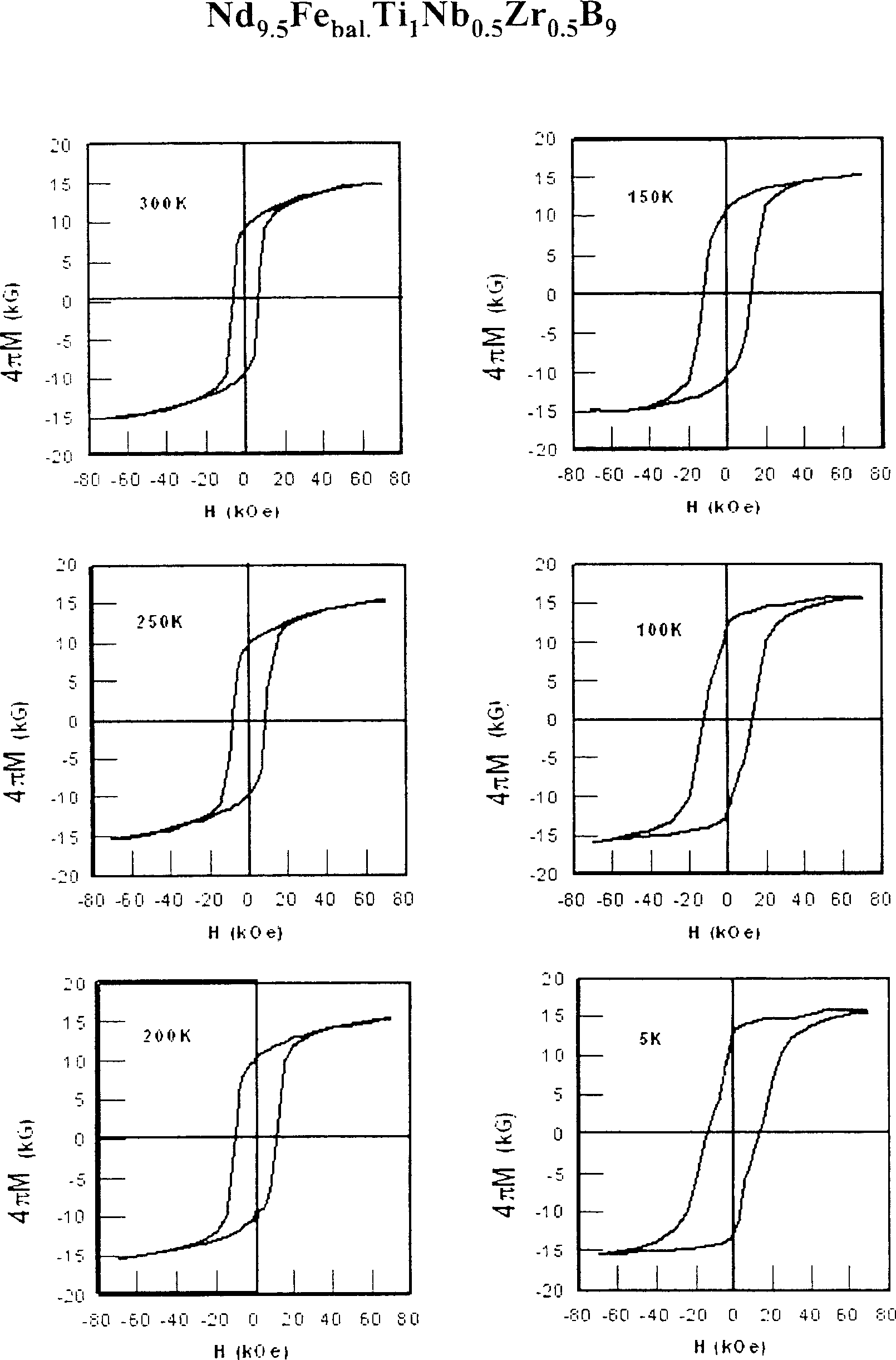

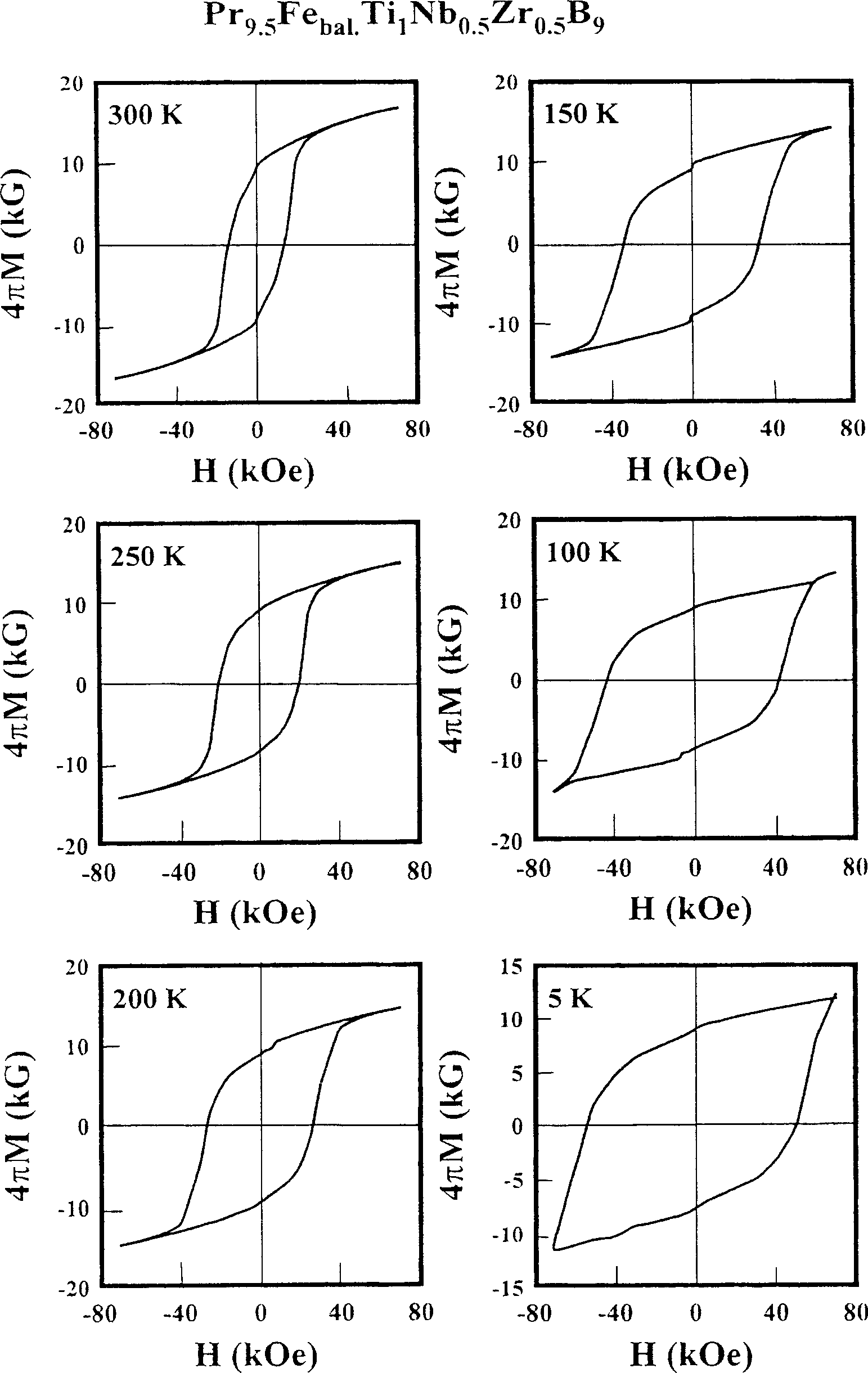

[0020] The present invention uses the higher anisotropy field Pr 2 Fe 14 B replaces Nd 2 Fe 14 B, to increase the intrinsic coercivity of the magnetic alloy ribbon at room temperature or low temperature ( i H c ) And squareness. When designing the composition, the present invention first uses the PrFeB ternary alloy to obtain the composition of high-performance and easy-to-magnetize magnetic powder, and then uses Nd as a small amount of substitution for Pr to increase the overall saturation magnetization of the alloy ribbon, and then By changing a series of process parameters to optimize the microstructure, the exchange coupling between the soft and hard magnetic phases is improved, thereby increasing the residual magnetization, the magnetic energy product and providing suitable coercivity.

[0021] The composition of the praseodymium-containing magnetic material of the present invention can be determined by atomic percentage (PrNd) x T 100-x-y-z X y Q z The composition formula of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com