Co-B/CeO2-SiO2 alloy catalyst, its preparation process and application

An alloy catalyst, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of insufficient catalytic activity and selectivity, achieve excellent catalytic activity and selectivity, and easy to operate. , the effect of excellent catalysis and activity selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

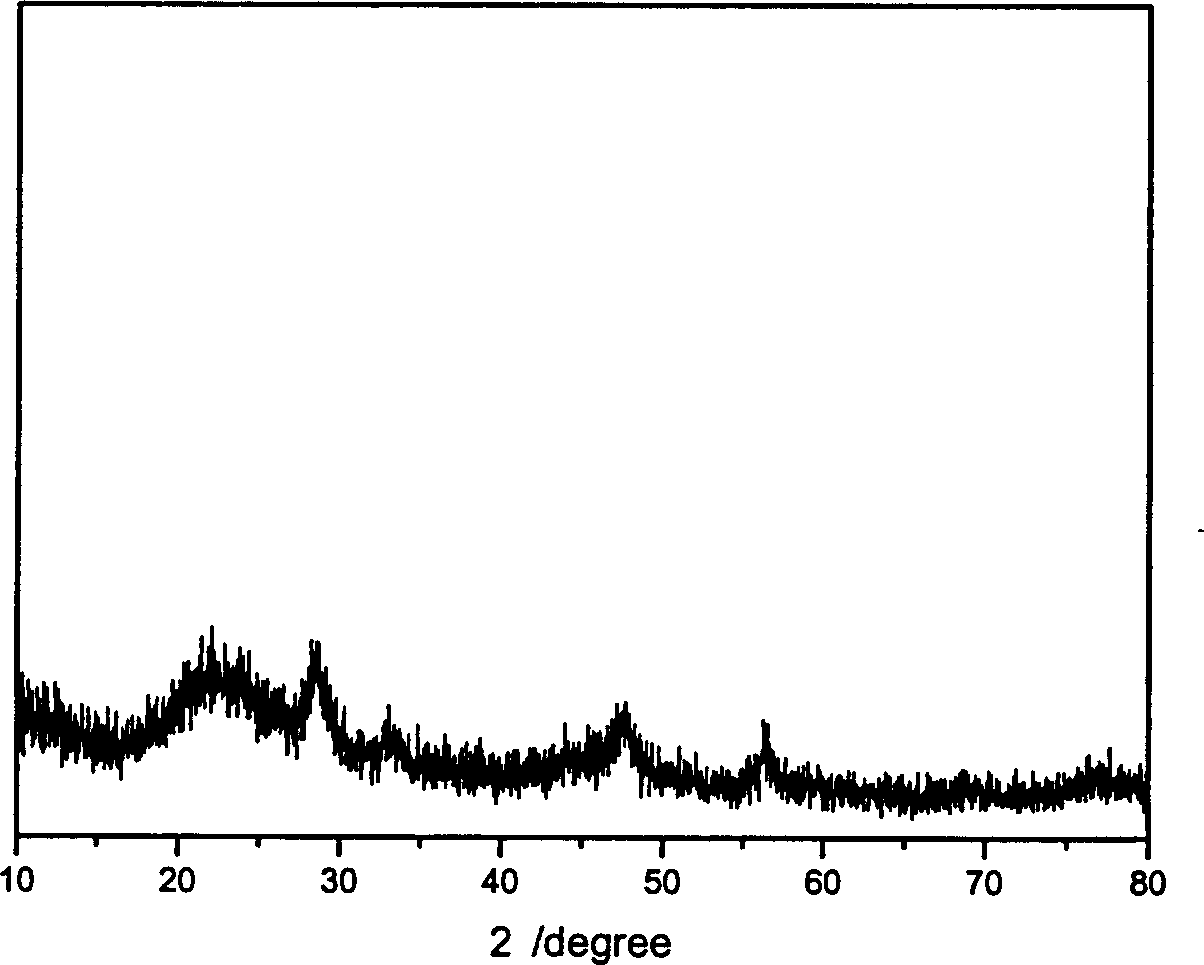

[0027] KBH 4 A mixed solution with a concentration of 2mol / L and a NaOH concentration of 0.2mol / L was added dropwise onto the prepared carrier (CeO 2 -SiO 2 ) Ce 3+ with Co 2+ The molar ratio of 1:10, control KBH 4 and Co 2+ The molar ratio is 5:1, react for 30 minutes to ensure the complete reduction of metal ions, and the reaction temperature is about 20 °C, then wash the prepared particles with deionized water until neutral, then wash with absolute ethanol to remove water, and collect Co -B / CeO 2 -SiO 2 Amorphous alloy catalyst, stored in absolute ethanol. The molar percentage of each component of the catalyst thus prepared is analyzed by ICP: Co: 17.9, Ce: 4.53%, B: 1.31%, totaling 23.74%, and the specific surface area measured by the dehydrogenation chemisorptions method is 87.3m 2 / g. X-ray diffraction pattern see figure 1 .

Embodiment 2~5

[0029] Using the same method as in Example 1, wherein the process parameters are shown in Table 2. Ce 3+ with Co 2+ The mol ratio is shown in Table 1:

[0030] Example

2

3

4

5

The molar ratio of

1∶22.6

1∶9.6

1∶3.4

1∶4.4

[0031] Table 2 Composition, specific surface area, and dispersion of catalysts with different Ce contents

[0032] Example Catalyst System Composition M co a S act b Temperature KBH 4 Concentration D. b

[0033] (m 2 / gCo) °C (mol / L) %

[0034] 1Co-B / SiO 2 co 67.4 B 325. 17.9% 30.0 20 2 4.5

[0035] 2Co-B / CeO 2 -SiO 2 co 72.0 B 38.0 18.5% 57.6 20 2 8.6

[0036] 3Co-B / CeO 2-SiO 2 co 67.9 B 32.1 17.9% 87.3 20 2 13.1

[0037] 4Co-B / CeO 2 -SiO 2 co 70.0 B 30.0 16.0% 67.5 20 2 10.9

[0038] 5Co-B / CeO 2 -SiO 2 co 68.6 B 31.4 13.8% 37.8 20 2 5.6

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com