Method for producing fermented potash fertilizer by bacterium enzymatic treatment of potassium-containing rock and preparing organic-inorganic compound mixed fertilizers

A technology for fermenting potash fertilizers and potash rocks is applied in the field of biochemical fertilizers, which can solve the problems of using many equipment, expensive ingredients, and difficult to implement, and achieves the effects of eliminating pollution, saving equipment and improving soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

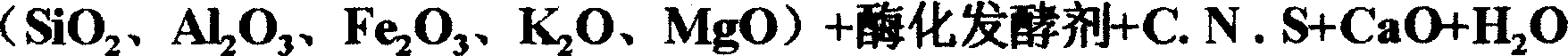

[0031] Potassium (K) in Zheng'an County, Guizhou Province 2O) 9.77% potassium-containing shale, take 96% potassium shale by weight and 4% bone by weight, mix and pulverize, and prepare 80 mesh fermented potassium matrix powder.

[0032] Add 25% by weight of additives to 50% by weight of enzyme base, add 15% by weight of coal waste, and 10% by weight of organic humic acid from tung husks, mix, pulverize, and stir well to prepare the enzymatic fermentation agent.

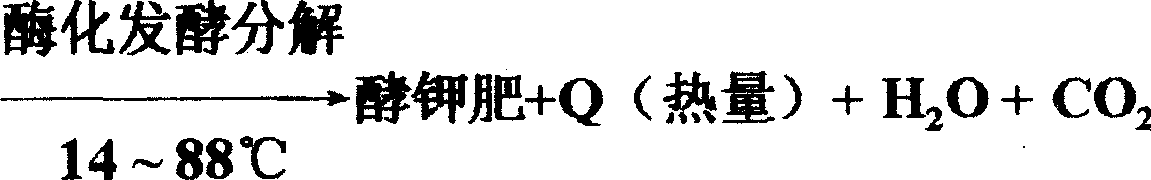

[0033] Take 75% by weight of fermented potassium matrix powder and 25% by weight of enzymatic starter, mix and pulverize, add water to stir evenly, stack and ferment, and heat up from normal temperature 17°C to 65°C, continue stacking for 25 days, and then cool down for 20 days, Cool to normal temperature 17°C, and then prepare fermented potash fertilizer.

[0034] The above-mentioned fermented potassium fertilizer produced, after detection and analysis, it contains: K 2 O 7.74%, organic matter 11.8%, P 2 o 5 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com