Lutein extracting process from marigold flower

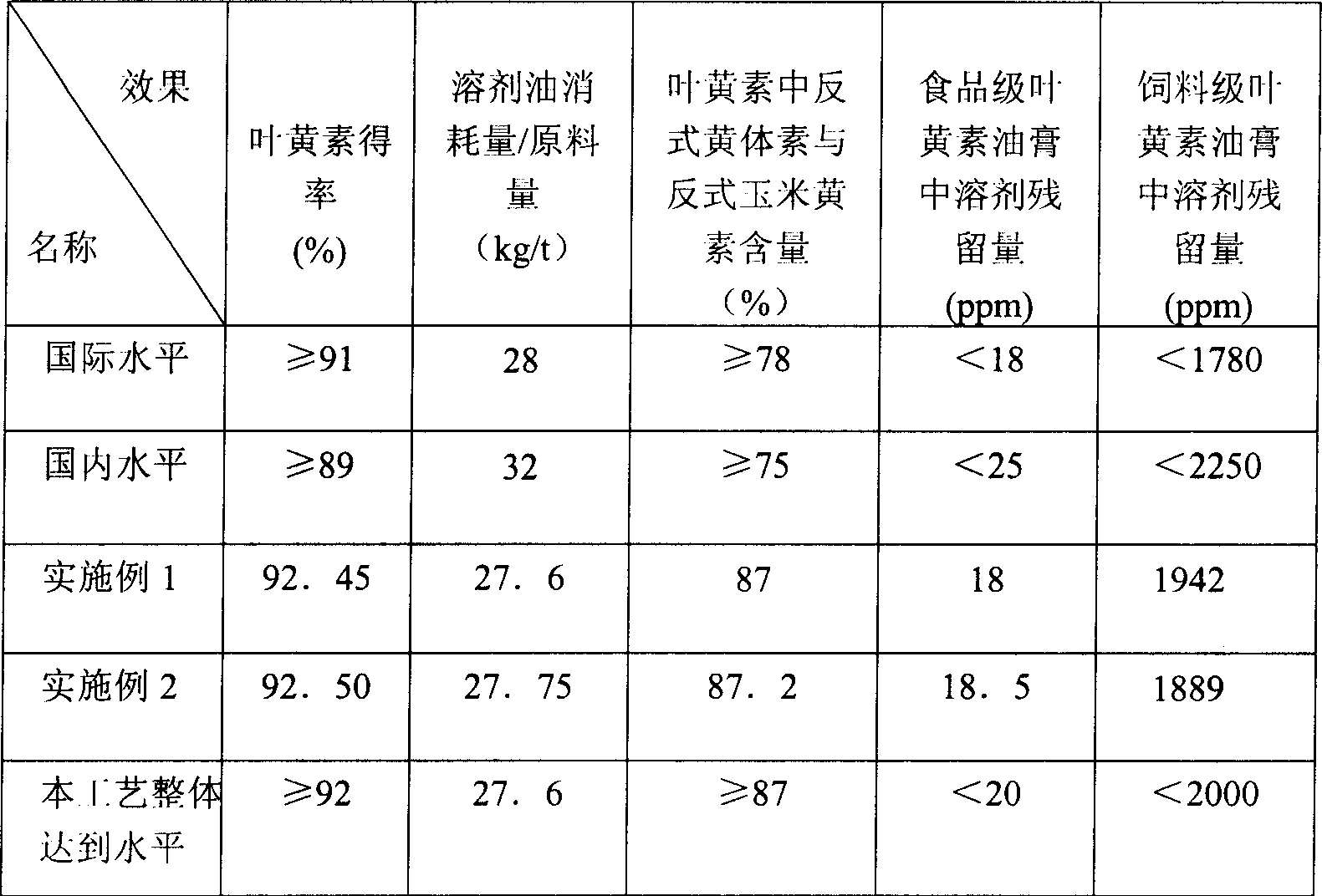

A technology of marigold flowers and lutein, applied in the direction of organic chemistry, etc., can solve the problems of large solvent consumption per ton of raw materials, low trans-lutein content, low lutein yield, etc., so as to reduce the solvent content, reduce Production cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Example 1: 163.51 tons of marigold granule raw materials with a specification of 3-5mm, a water content of 13.5%, and a dust content of 9.6% were transported to a platform-type rotary extractor by a scraper conveyor, and passed through six solvent pumps. Continuous countercurrent leaching, the upper temperature of the extractor is 48°C and the negative pressure is maintained, and the leaching time is 150 minutes. The lutein is continuously countercurrent leached by solvent oil and dissolved by solvent oil to form a saturated solution. After leaching, it passes through the silo of 60 mesh Filter through a mesh to separate the residue from the saturated solution. The slag is evaporated by negative pressure steam at 126°C through the residue steamer, the slag discharge temperature is 80°C, the lutein content is 0.3g / kg, the temperature of the hot water tank is 79°C, and the solvent oil contained in the residue is evaporated by the residue steamer , and enter the condenser ...

Embodiment 2

[0027] Example 2: 126.51 tons of marigold granule raw materials with a specification of 3-5mm, a water content of 12%, and a dust content of 8.9% were transported to a platform-type rotary extractor by a scraper conveyor, and passed through six solvent pumps. Continuous countercurrent leaching, the temperature of the upper part of the extractor is 46.5°C and the negative pressure is maintained, and the leaching time is 110 minutes. The lutein is continuously leached by solvent oil in countercurrent and dissolved by solvent oil to form a saturated solution. After leaching, it passes through the silo of 60 mesh Filter through a mesh to separate the residue from the saturated solution. The slag is evaporated with negative pressure steam at 121.5°C through the residue steamer, the slag discharge temperature is 75°C, the lutein content is 0.37g / kg, the temperature of the hot water tank is 80.5°C, and the solvent oil contained in the residue is evaporated by the residue steamer , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com