Thermal tube and producing method thereof

A manufacturing method and technology of heat pipes, which are applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of increasing liquid return resistance, reducing the amount of working liquid, increasing capillary force, etc., to improve heat transfer. performance, improved reliability, and faster reflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

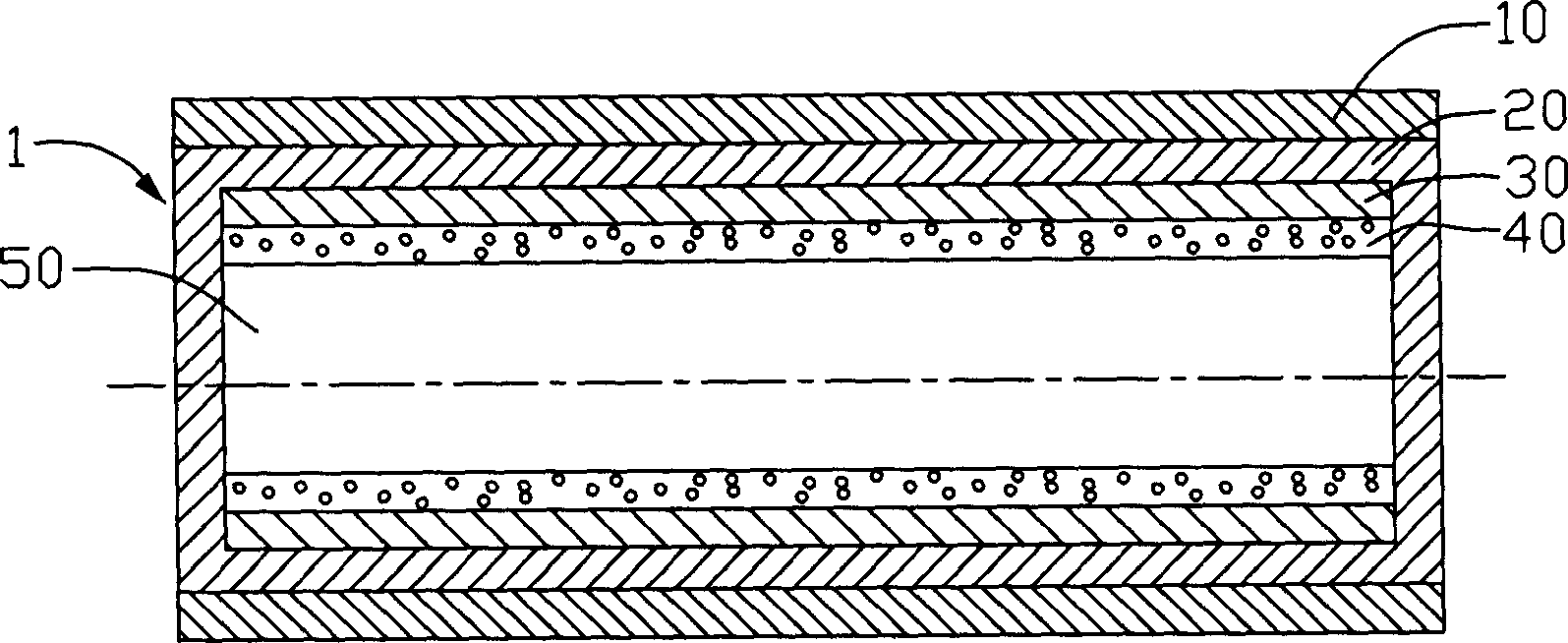

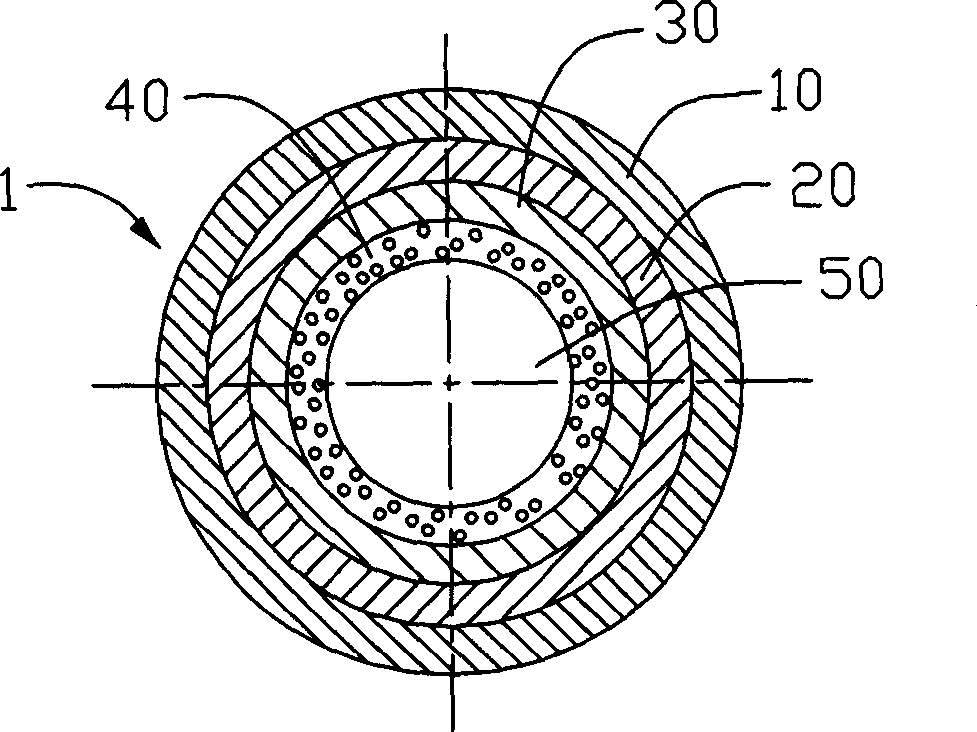

[0013] Please refer to Figure 1 to Figure 2 As shown in the heat pipe of the present invention, the shell of the heat pipe 1 has four layers, from the outside to the inside of the heat pipe 1, there are protective layer 10, shell layer 20, capillary structure layer 30 and hydrophilic layer 40, and the cavity of the heat pipe 1 50 contains an appropriate amount of working medium, the working medium is selected from liquids with low boiling point and stable chemical properties such as ethanol, pure water, etc., and nano powders such as carbon nanotubes, nano carbon spheres, nano copper powder particles or their The mixture to increase the heat transfer of the working medium. Wherein, the protective layer 10 is made of nano-materials, such as carbon nanotubes, nano-copper, nano-aluminum, and nano-copper-aluminum alloys. The above-mentioned nano-materials can be deposited on the shell layer 20 to form a layer by vacuum coating technology. A film layer with a thickness between 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com