Test circuit of liquid crystal display and test method

A liquid crystal display and test circuit technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as poor efficiency of liquid crystal display test lines, and achieve the effects of improving test efficiency, enhancing competitiveness, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Since the liquid crystal display test circuit of the present invention is based on the concept of grouping based on the number of sub-pixels, here only the embodiment when the number of sub-pixels is 3 and 4 is used as an illustration, and the number of other sub-pixels can also be based on this method. The concept of invention grouping can be implemented in detail, so it will not be described in detail.

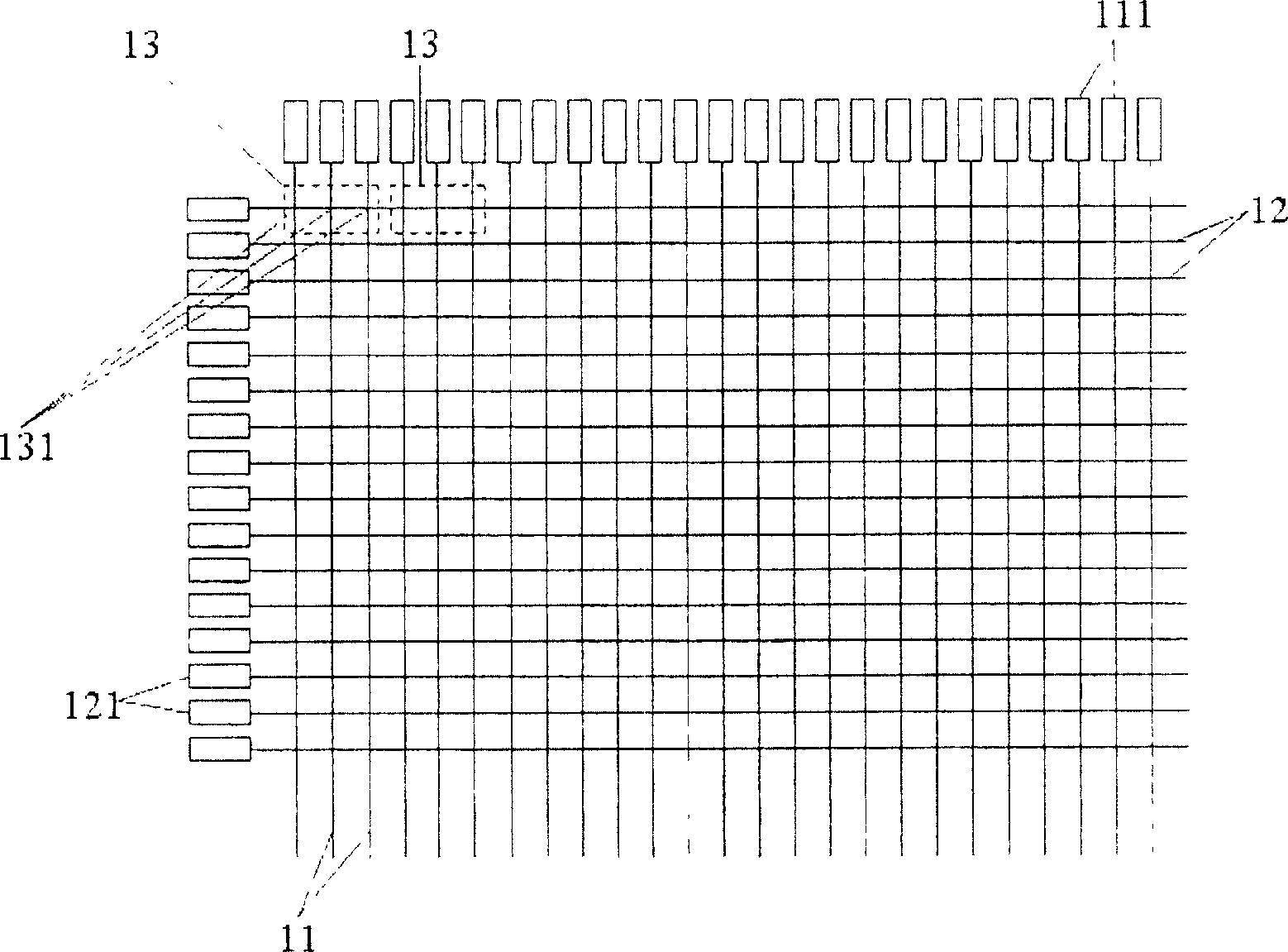

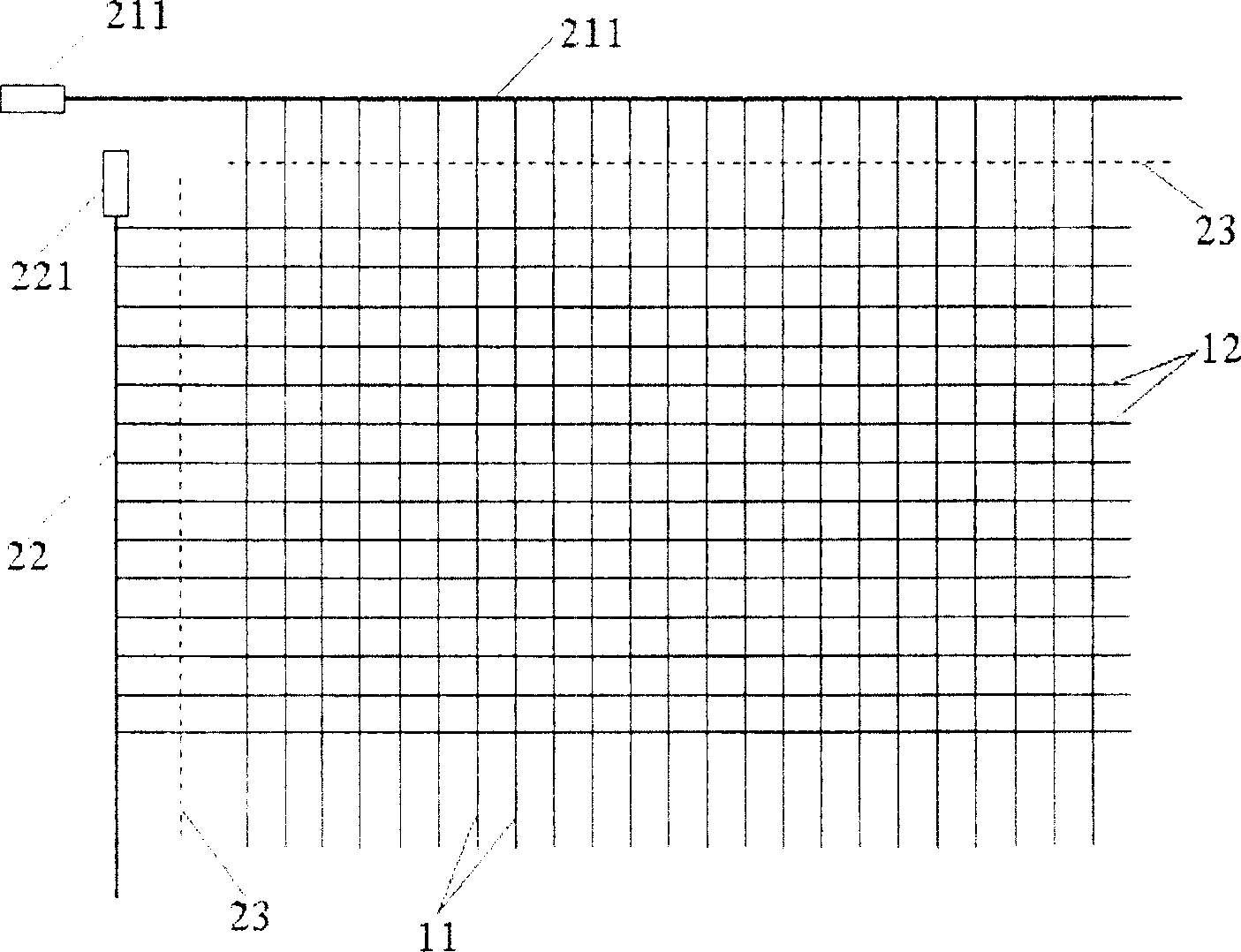

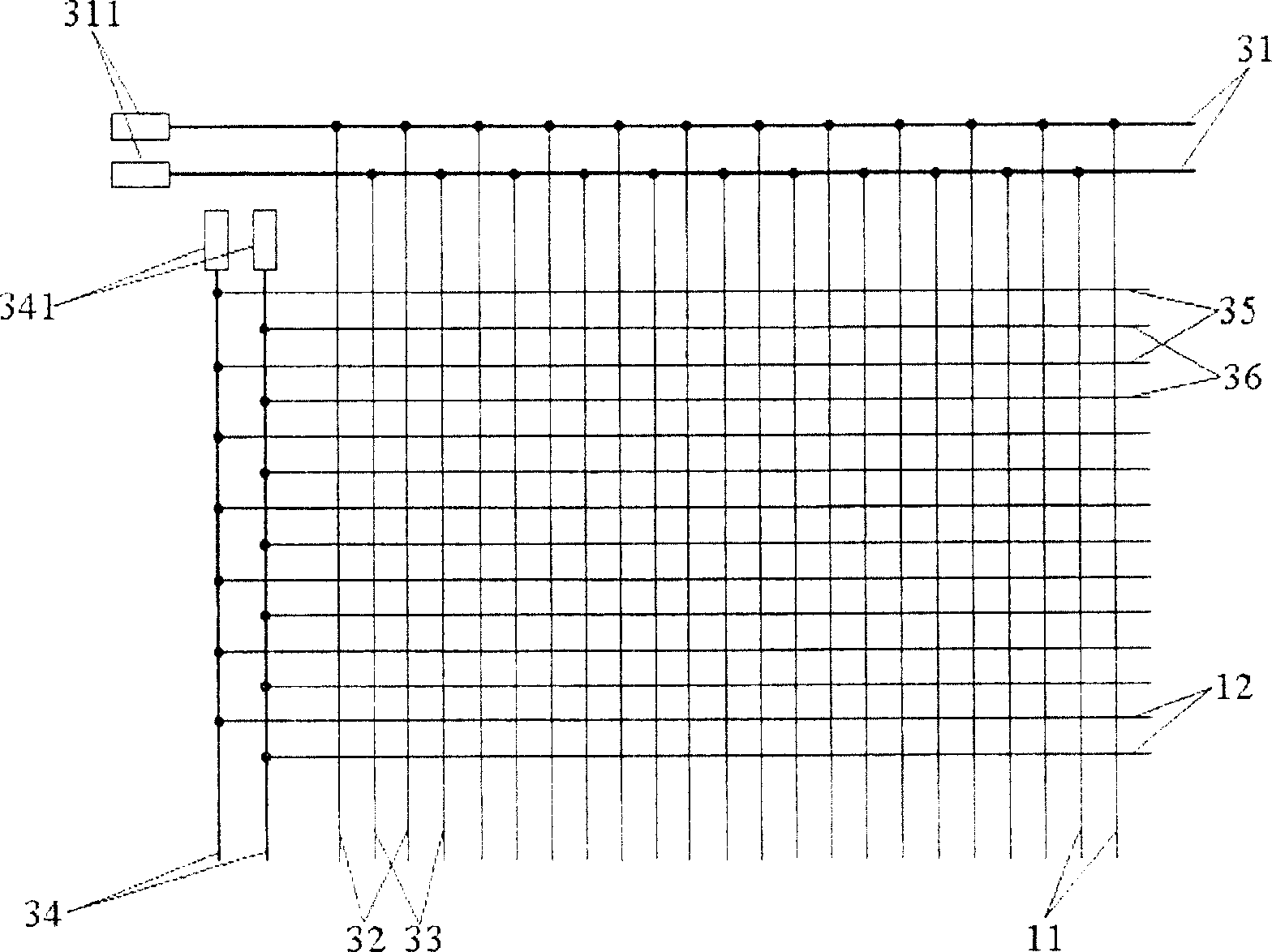

[0070] see Figure 5 , which is a schematic diagram of a liquid crystal display test circuit according to the present invention, which is particularly an embodiment with three sub-pixels, including a substrate, a plurality of pixel structures 51, a plurality of data lines 52 and six shorting bars 53, wherein The substrate can be a glass substrate or a flexible substrate, and a plurality of pixel structures 51 are formed on the substrate, and each pixel structure 51 has three sub-pixels 511, and a plurality of data lines 52 are formed on the substrate, and Correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com