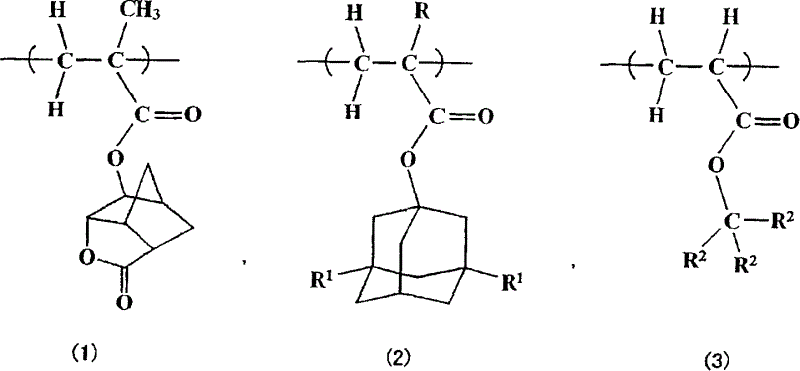

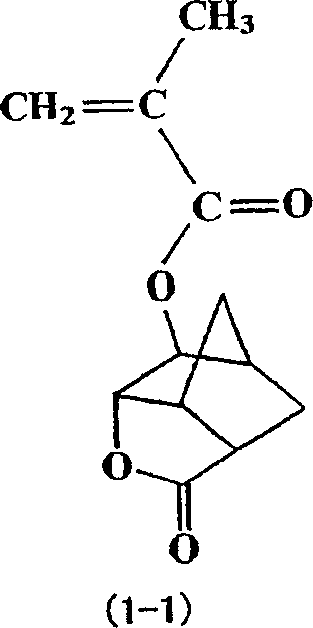

Acrylic copolymer and radiation-sensitive resin composition

A resin composition and acrylic technology, applied in the field of acrylic copolymers and radiation-sensitive resin compositions, can solve the problems of no thermal deformation technology, adverse effects on resolution, etc., and achieve reduced line width variation and high surface dry spot. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111]

[0112] (4-1) (4-2) (4-3)

[0113] Prepare to dissolve 55.00 g (50 mol %) of compound (4-1), 11.70 g (10 mol %) of compound (4-2), and 33.31 g (40 mol %) of compound (4-3) in 200 g of 2-butanone 4.56 g of dimethyl azobisisobutyrate was added to the monomer solution, and a 1000 ml three-necked flask into which 100 g of 2-butanone had been added was purged with nitrogen for 30 minutes. After nitrogen purging, the reactor was heated to 80° C. while stirring, and the above-mentioned monomer solution prepared in advance was added dropwise over 4 hours using a dropping funnel. The start of the dropwise addition was regarded as the start time of the polymerization, and the polymerization reaction was carried out for 6 hours. After the polymerization is completed, the polymerization solution is cooled to below 30° C. by water cooling, poured into 2000 g of a mixed solvent of 2-propanol / n-heptane=1 / 2, and the precipitated white powder is filtered. The filtered ...

Embodiment 2

[0115]

[0116] (5-1) (5-2) (5-3)

[0117] Prepare to dissolve 54.57g (50 mol%) of compound (5-1), 12.39g (10 mol%) of compound (5-2) and 33.04g (40 mol%) of compound (5-3) in 200g of 2-butanone 4.52 g of dimethyl azobisisobutyrate was added into the monomer solution, and a 1000 ml three-neck flask into which 100 g of 2-butanone had been added was purged with nitrogen for 30 minutes. After nitrogen purging, the reactor was heated to 80° C. while stirring, and the above-mentioned monomer solution prepared in advance was added dropwise over 4 hours using a dropping funnel. The start of the dropwise addition was regarded as the start time of the polymerization, and the polymerization reaction was carried out for 6 hours. After the polymerization is completed, the polymerization solution is cooled to below 30° C. by water cooling, put into 2000 g of a mixed solvent of 2-propanol / n-heptane=1 / 2, and the precipitated white powder is filtered. Use the mixed solvent 400...

Embodiment 3

[0119]

[0120] (6-1) (6-2) (6-3)

[0121] Prepare to dissolve 55.38g (50 mol%) of compound (6-1), 11.08g (10 mol%) of compound (6-2) and 33.54g (40 mol%) of compound (6-3) in 200g of 2-butanone 4.59 g of dimethyl azobisisobutyrate was added into the monomer solution, and a 1000 ml three-necked flask into which 100 g of 2-butanone had been added was purged with nitrogen for 30 minutes. After nitrogen purging, the reactor was heated to 80° C. while stirring, and the above-mentioned monomer solution prepared in advance was added dropwise over 4 hours using a titration funnel. The start of the dropwise addition was regarded as the start time of the polymerization, and the polymerization reaction was carried out for 6 hours. After the polymerization is completed, the polymerization solution is cooled to below 30° C. by water cooling, poured into 2000 g of a mixed solvent of 2-propanol / n-heptane=1 / 2, and the precipitated white powder is filtered. Use the mixed solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com