Method for detecting corrosive sulfur content in crude oil or fraction oil

A technology of corrosive sulfur and determination method, applied in chemical method analysis, measuring device, analysis material, etc., can solve the problem of inability to measure the content of corrosive sulfur, and achieve the effect of increasing comparability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

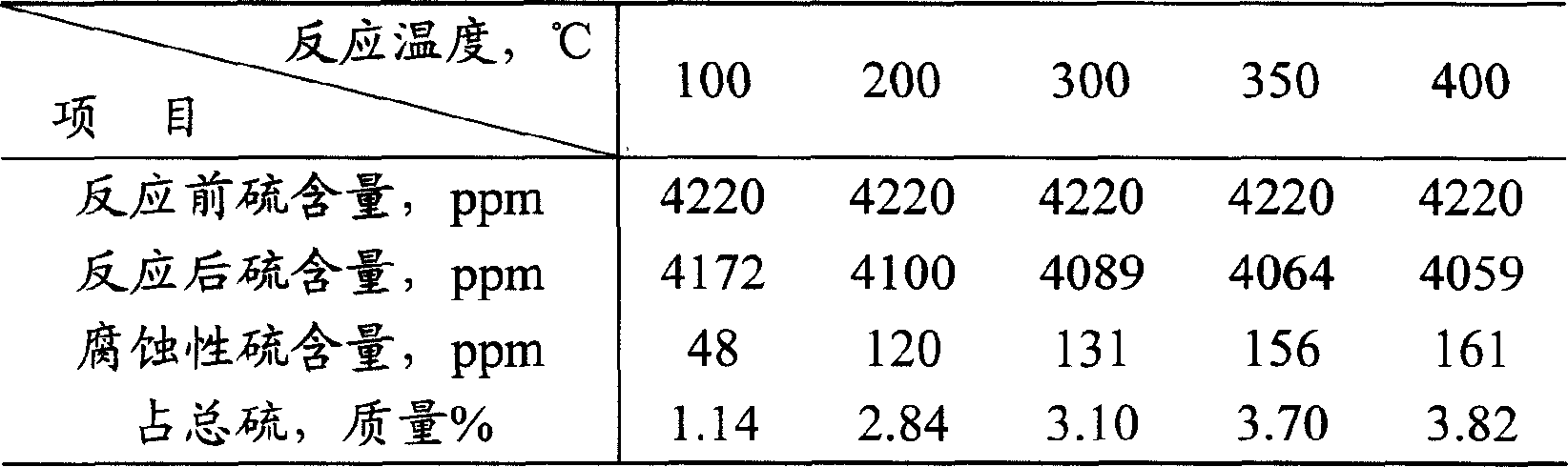

[0017] 30 grams of distillate oil samples with a distillation range of 15 to 350° C. were introduced into a closed autoclave with stirring and temperature and pressure controllers, and the sulfur content of the samples was 4220 ppm. Add 5 grams of iron powder, heat up to the specified temperature and react for 1 hour under stirring. Then cool with air to lower the temperature in the autoclave to 150°C, and then cool the autoclave to room temperature with cooling water. The sulfur content was measured in the solution, and the results of the measurements at different reaction temperatures are shown in Table 1.

[0018] It can be seen from Table 1 that the content of corrosive sulfur is less at lower reaction temperatures, and the amount of corrosive sulfur gradually increases with the increase of temperature. When the reaction temperature is greater than 350 °C, the content of corrosive sulfur tends to Stablize. Therefore, the optimum reaction temperature for determining the c...

example 2

[0020] This example examines the influence of reaction time on the measurement results.

[0021] The content of corrosive sulfur in the distillate was measured according to the method of Example 1, and the controlled reaction temperature was 350°C. The corrosive sulfur content measured under different reaction times is shown in Table 2.

[0022] It can be seen from Table 2 that the reaction time between iron powder and oil sample is too short, and the measurement result is low due to insufficient reaction. When the reaction time exceeds 1.0 hour, prolonging the reaction time has no obvious influence on the measurement result. Therefore, the appropriate reaction time should be more than 1.0 hour.

example 3

[0024] This example examines the influence of the amount of iron powder added on the measurement results.

[0025] Measure the corrosive sulfur content of distillate oil by the method of example 1, add different amounts of iron powder respectively in distillate oil, control reaction temperature to be 350 ℃, time is 1 hour, measurement result is shown in Table 3. The data in Table 3 shows that when the amount of iron powder added is 2-10 grams, that is, when it accounts for more than 6.7% by mass of the distillate oil sample, it has no obvious influence on the determination of the corrosive sulfur content of the distillate oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com