Azimuth measuring instrument with spin valve giant magnetoresistance element

A spin valve, giant magnetoresistance technology, applied in the size/direction of the magnetic field, measuring device, measuring magnetic variables and other directions, can solve the problems of high power consumption, low resistance, increase the size of the azimuth measuring instrument, etc., to simplify manufacturing Process, easy to manufacture, achieve anisotropic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

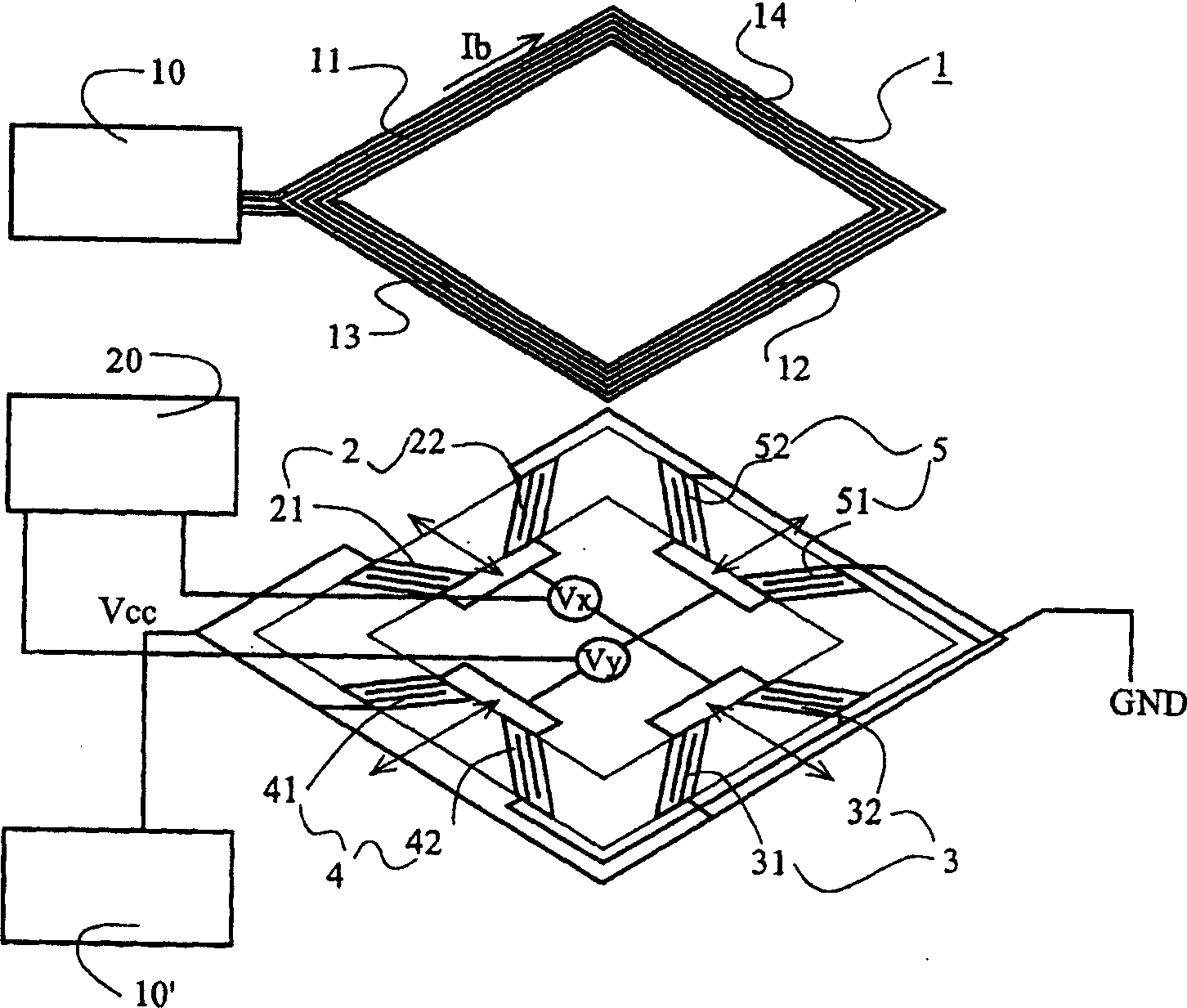

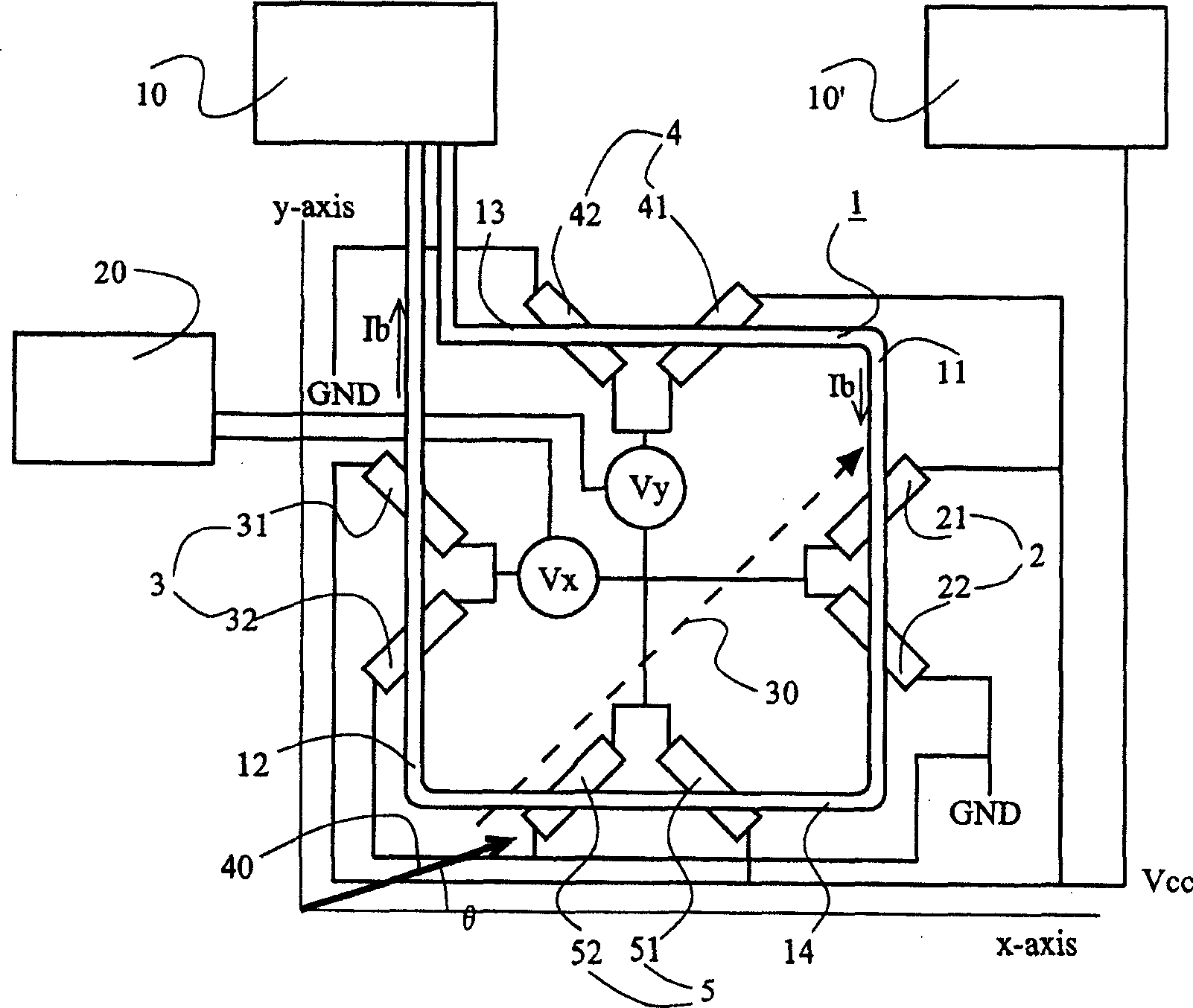

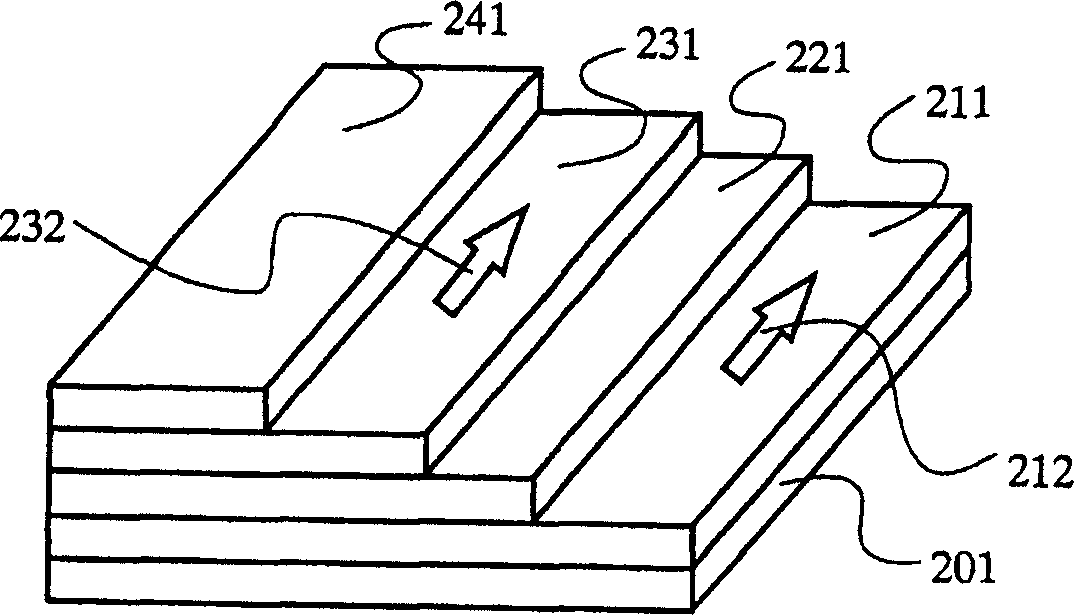

[0093] Figure 13 The azimuth measuring instrument according to Embodiment 2 of the present invention is shown in the form of a circuit diagram. In this embodiment, the longitudinal direction of one spin-valve giant magnetoresistance element of each spin-valve giant magnetoresistance element pair intersects only one of the pair of opposite sides of planar coil 1 substantially at 45 degrees. In addition, the longitudinal direction of the other spin-valve giant magnetoresistance element of each spin-valve giant magnetoresistance element pair intersects only one pair of opposite sides and the other of the planar coil 1 substantially at 45 degrees. Therefore, one spin valve giant magnetoresistance element 21 of the spin valve giant magnetoresistance element pair 2 intersects with one side 11 of the planar coil 1, and the other spin valve giant magnetoresistance element of the spin valve giant magnetoresistance element pair 2 22 intersects side 12 opposite side 11. A spin valve g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com