Roller for a fibre-processing machine

一种纤维处理、机械的技术,应用在罗拉领域,能够解决不适合圆筒端部和整个内部和毂部区域、难控制加载情况和操作条件等问题,达到宽工作宽度、改良减速值、高生产速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

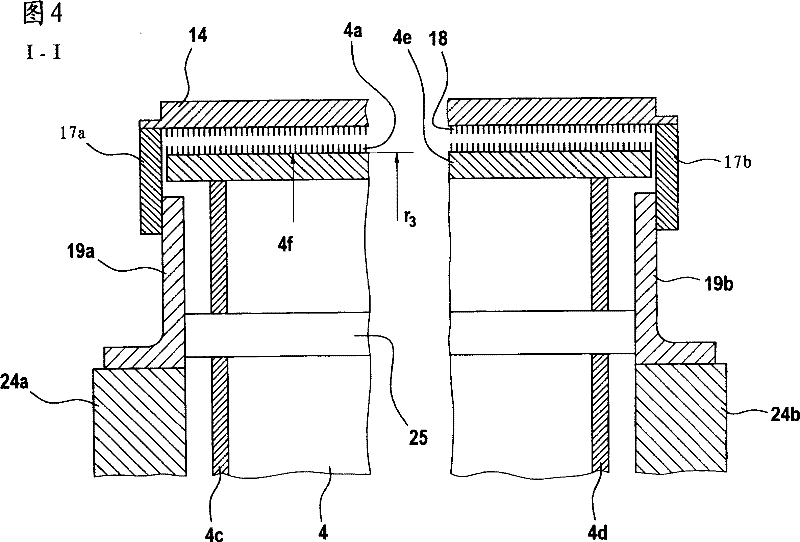

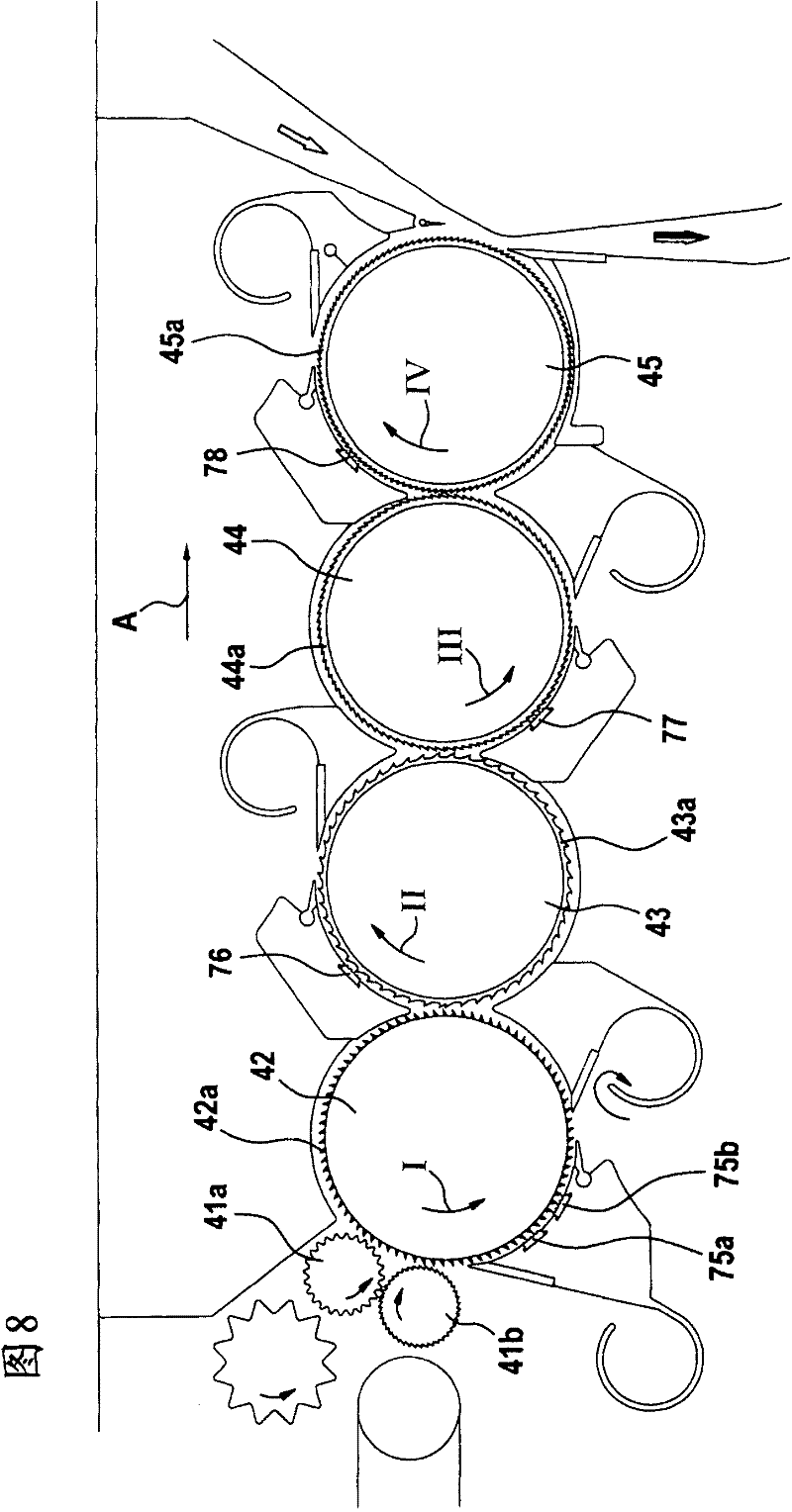

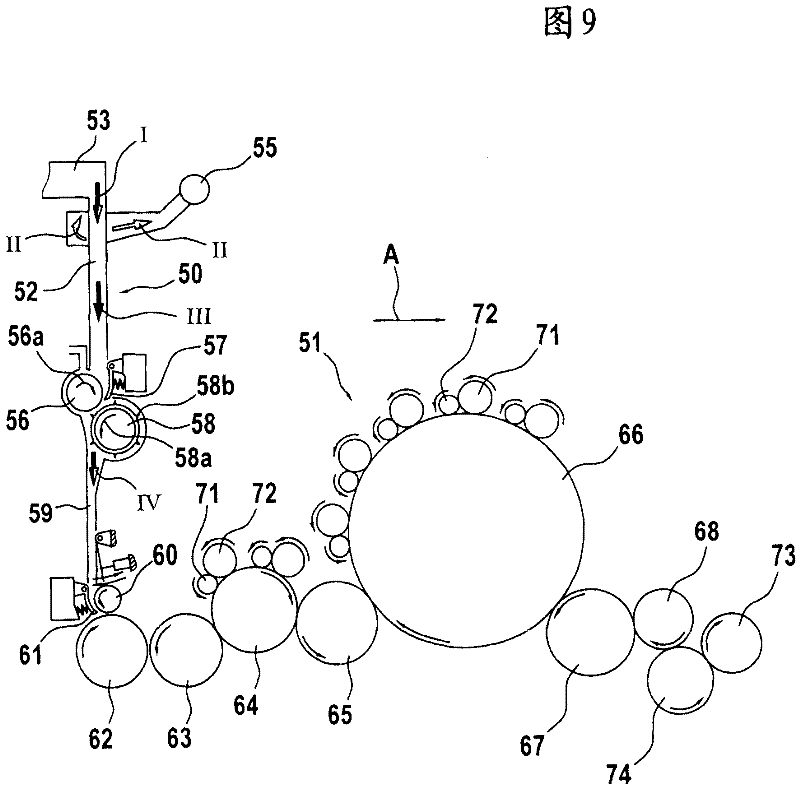

[0020] figure 1 Shows a flat card, for example a Trützschler TC 03 flat card, with feed roller 1, feed table 2, licker-in rollers 3a, 3b, 3c, cylinder 4, doffer 5, stripping roller 6, Rollers 7, 8, web guide elements 9, web funnel 10, draw-off rollers 11, 12, revolving card flats 13 with card flat deflection rollers 13a, 13b and card flat racks 14, cans 15 and rings Bar device 16. The curved arrows represent the direction of rotation of the rollers. Reference sign M represents the center (axis) of the cylinder 4 . Reference numeral 4a designates the card clothing and reference numeral 4b designates the direction of rotation of the cylinder 4 . Reference sign B represents the rotation direction of the rotary carding flat 13 in the combing position, and reference sign C represents the direction in which the carding flat rack 14 moves on the opposite side. Reference numerals 23', 23" designate fixed carding members, reference numeral 39 designates the hood below the cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com