Fuel cell system

A fuel cell system and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of reduced power generation capacity and concentration, and achieve the effect of realizing power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

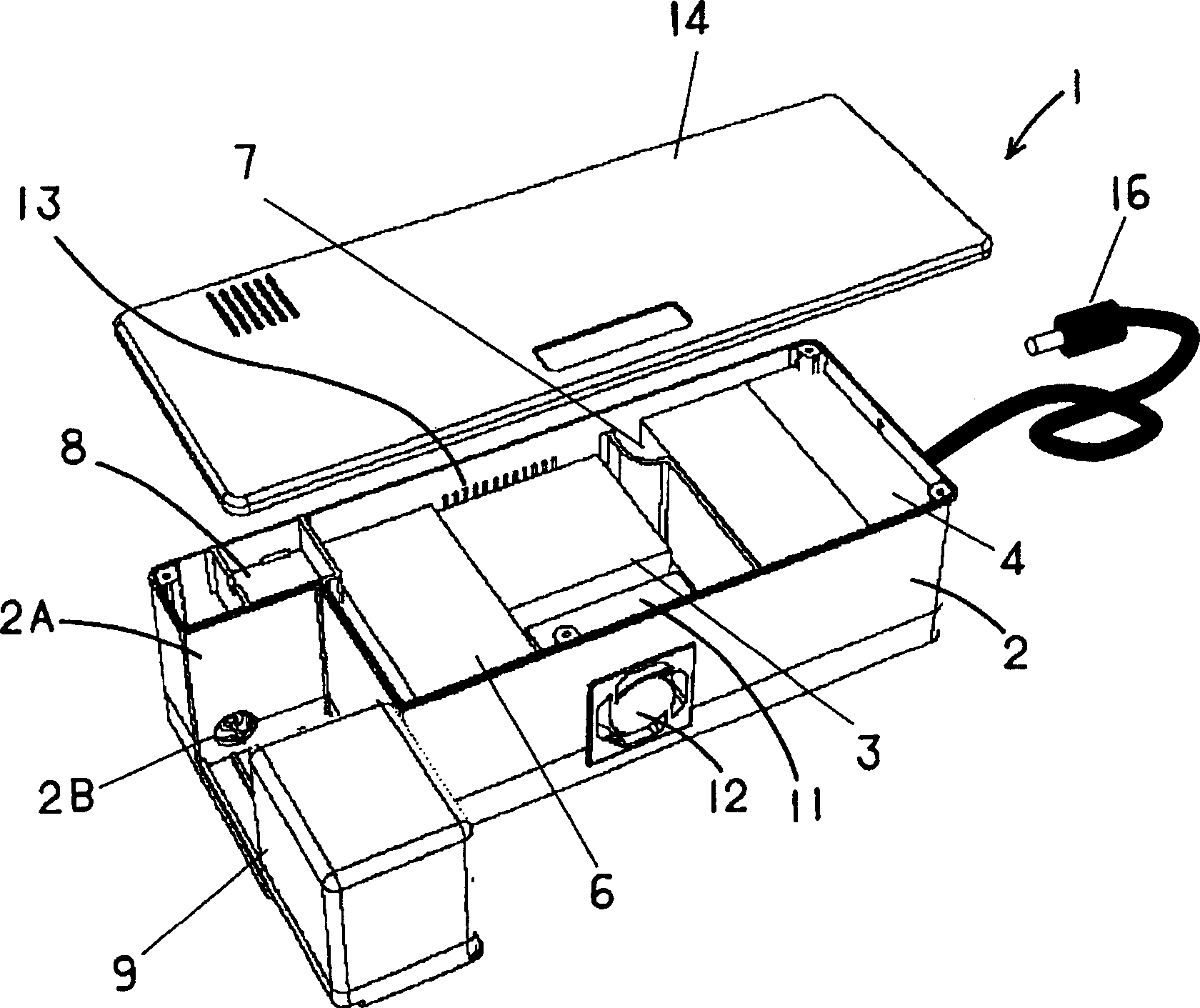

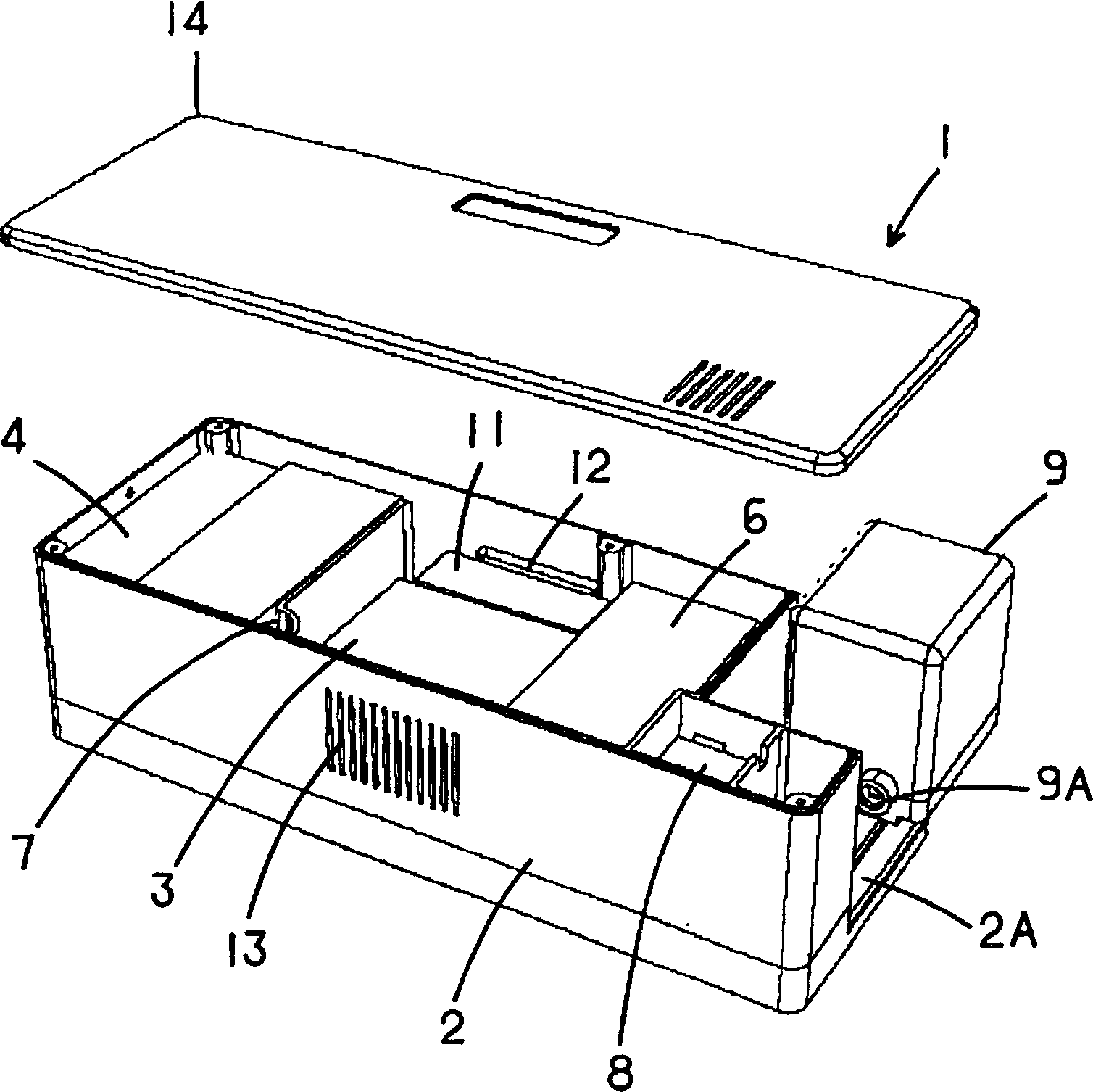

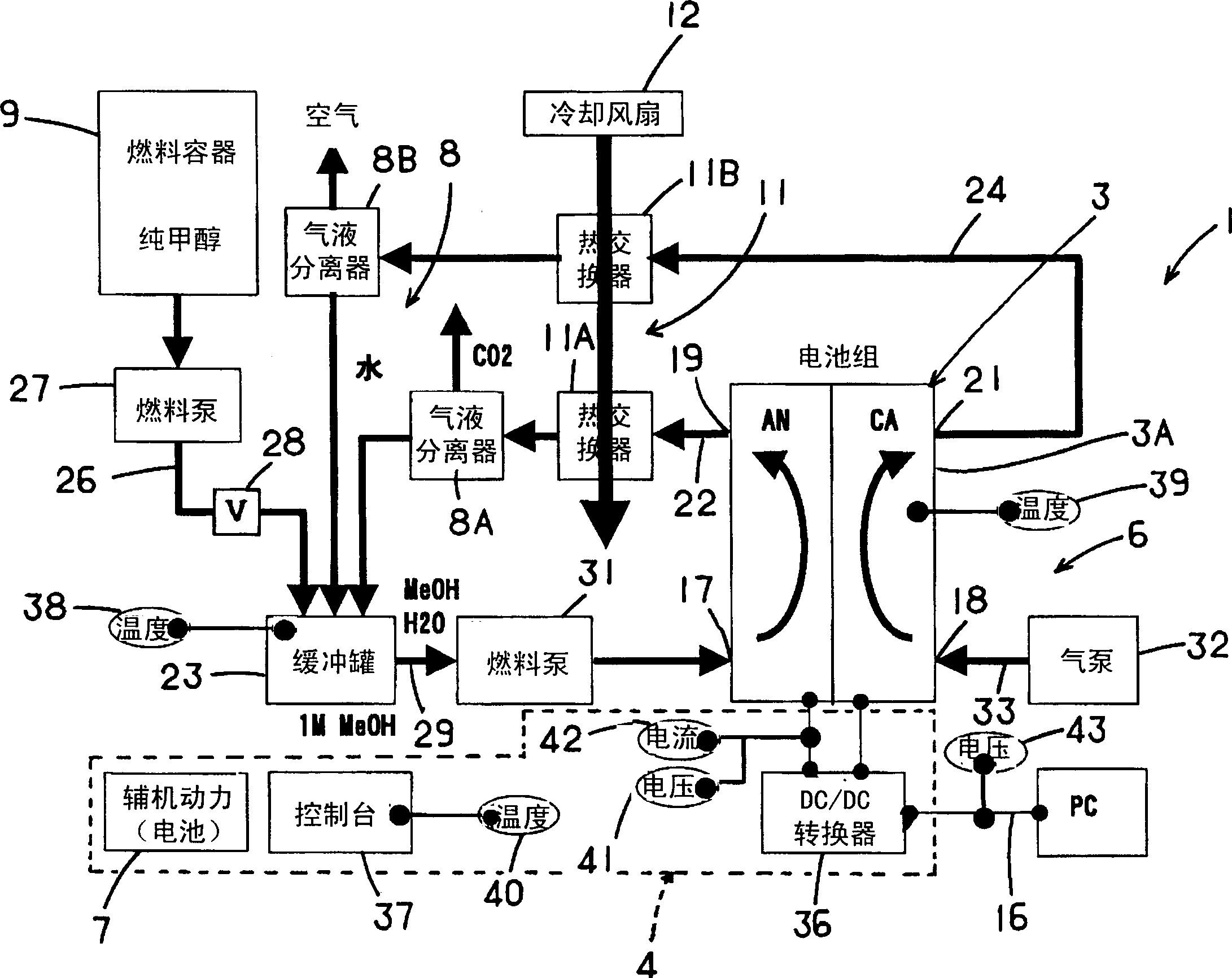

[0054] figure 1 A front perspective view showing a fuel cell system 1 using an embodiment of the present invention, figure 2 Represents the same rear perspective view, image 3 A configuration diagram of the fuel cell system 1 is shown. The fuel cell system 1 of the embodiment is a so-called Direct Methanol Fuel Cell (DMFC) that generates electricity by using methanol as a liquid fuel and electrochemically reacting the methanol with air as an oxidant in a fuel cell cell. The system is compact in overall size so that it can be used as a power source for a portable notebook personal computer, for example.

[0055] That is, the fuel cell system 1 is figure 1 and figure 2 A fuel cell (battery pack) 3 is mounted in the approximate center of the box 2 shown, a control unit 4 is provided on one side in the longitudinal direction, and an auxiliary unit 6 is provided on the opposite side. In addition, an auxiliary power (secondary battery) 7 is provided between the control unit ...

Embodiment 2

[0079] under, Figure 9 A configuration diagram showing the vicinity of the fuel supply pipe 26 of the fuel cell system 1 according to another embodiment of the present invention. and, Figure 9 The structure of the fuel cell system 1 at this time from the fuel container 9 to the buffer tank 23 is extracted and shown, and the other parts are the same as image 3 same. At this time, on the fuel supply pipe 26, instead of image 3 , Figure 4 In this case, the solenoid valve 28 is connected to the discharge side and the suction side of the fuel pump 27 as a three-way valve 51 (solenoid valve 1 ) and a three-way valve 52 (solenoid valve 2 ) as flow path switching means. One end of the air bubble recovery pipe 54 is also connected to the three-way valve 51. One end of the air bubble recovery pipe 54 communicates with the upper part of the fuel supply pipe 26, and the other end of the air bubble recovery pipe 54 communicates with the sub-fuel tank formed in the air-opening type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com