Nanometer film shaping machine

A nano-film, forming machine technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of affecting product quality, dust pollution, difficult to prepare film, etc., to ensure uniformity of tissue, The effect of avoiding dust pollution and chemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

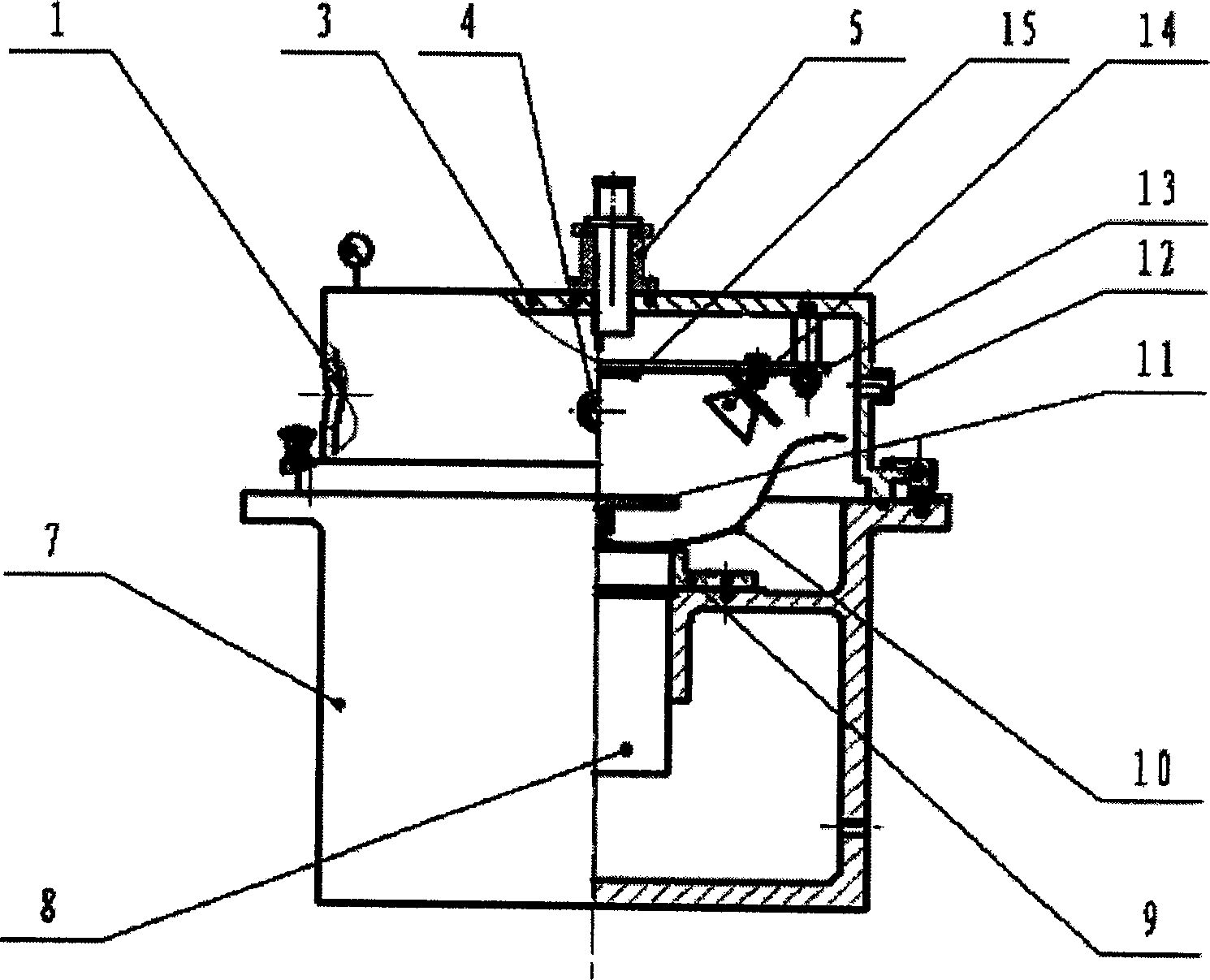

[0012] A nano-film forming machine for preparing nano-functional films, which is composed of a vacuum cabin body and a motor 8, the vacuum cabin body is composed of a cabin 7 and an upper cover 3, the upper cover 3 is arranged on the cabin 7, and the motor 8 is arranged on the In the cockpit 7 and fixed by the fixed flange 9 located on the cockpit 7, the base tray 11 is connected on the rotating shaft of the motor 8, and the upper cover 3 is provided with a liquid inlet and the liquid inlet is positioned above the base tray 11, A vacuum joint 4 for vacuuming is provided on the vacuum chamber body, and a heat source 14 for pyrolysis and a light source 15 for photolysis are arranged in the vacuum chamber body, and the heat source 14 and the light source 15 are placed higher than the base tray 11. In the embodiment, a liquid inlet 5 is connected to the liquid inlet, the cockpit 7 is a gray cast iron cockpit, and its grade is HT250, an observation window 1 is provided on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com