Method for preparing pigment-level titanium powder and coarse titanium white from blast slag containing titanium

A blast furnace slag, pigment grade technology, applied in the direction of titanium dioxide, fibrous filler, titanium oxide/hydroxide, etc., can solve the problem of difficulty in titanium leaching, and achieve the effect of low acid consumption, low temperature and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

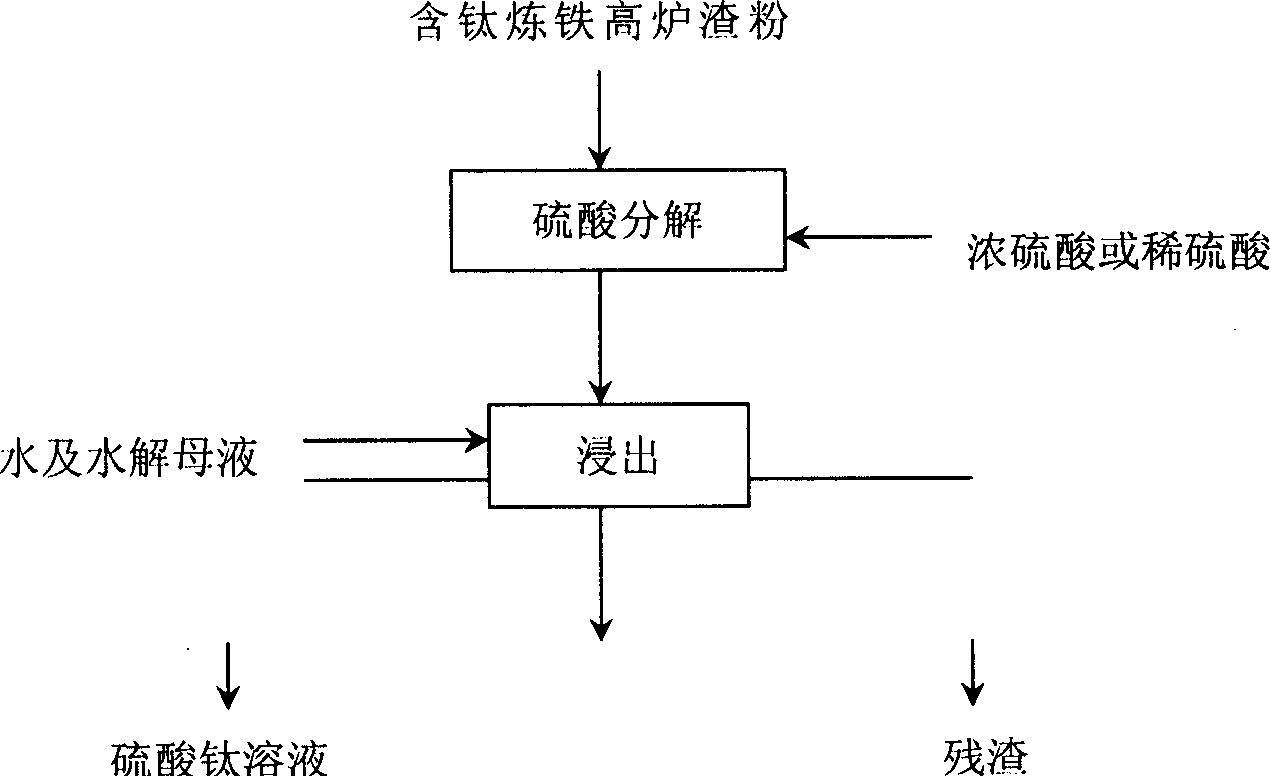

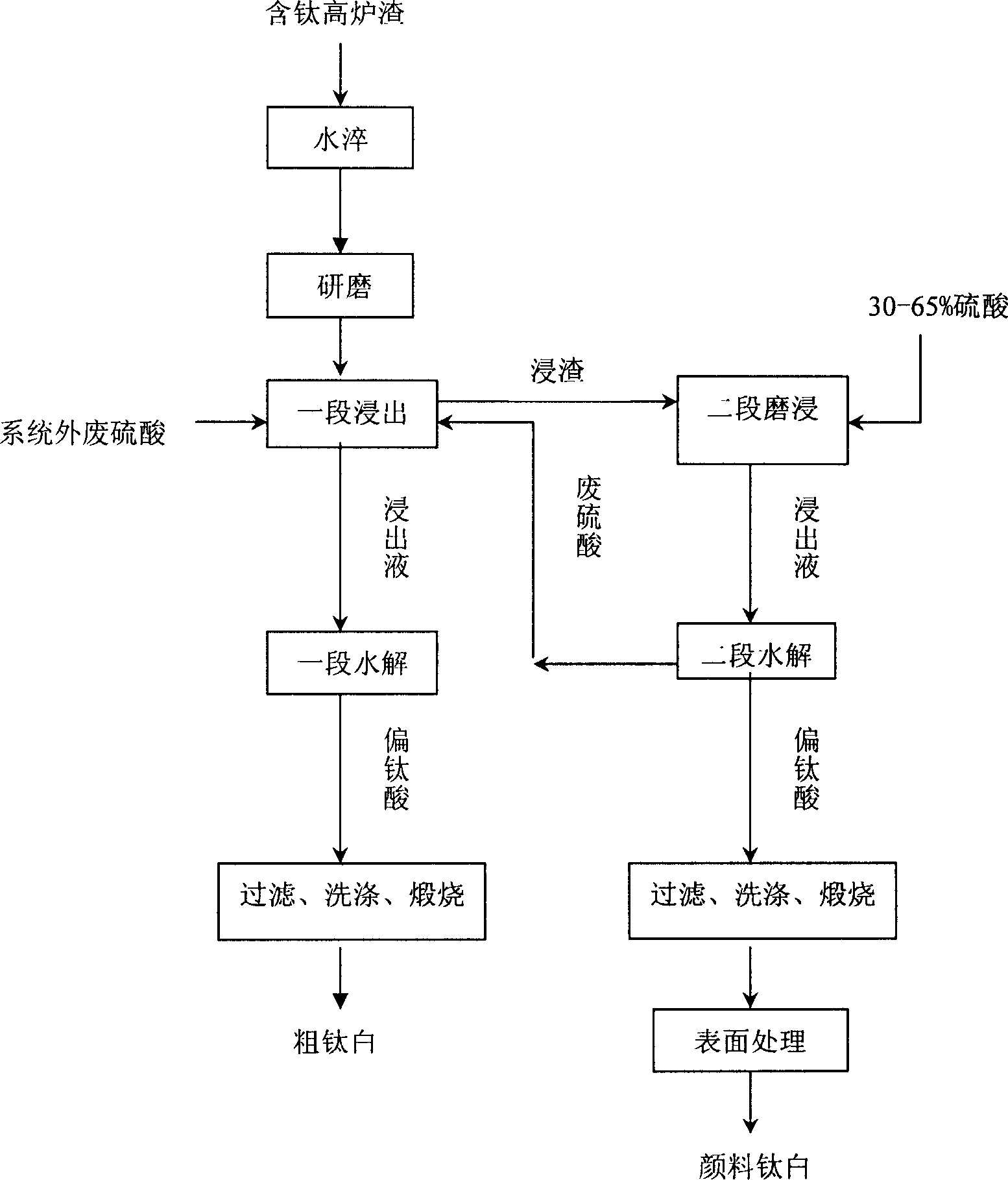

[0034] The process flow of this embodiment is as image 3 As shown, the process steps are as follows:

[0035] 1. Water quenching

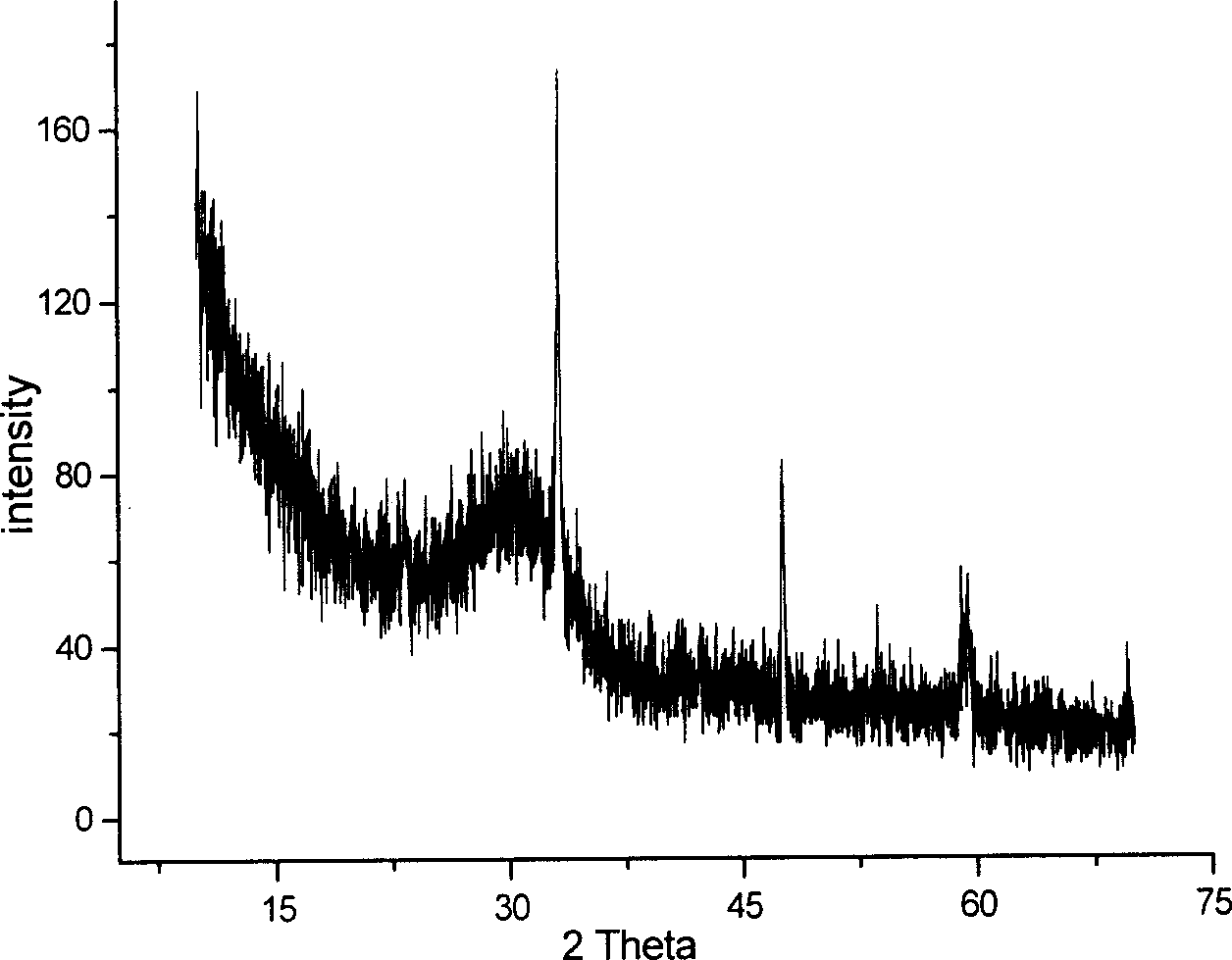

[0036] The molten titanium-containing blast furnace slag is sprayed with water at 10°C and quickly cooled to 30°C. The XRD pattern of the obtained water-quenched titanium-containing blast furnace slag is as follows figure 2 Shown

[0037] 2. Grinding

[0038] Grind the titanium-containing blast furnace slag after water quenching to 0.076~0.10mm, and the content of each component is TiO 2 22.49%, Al 2 O 3 13.69%, MgO 7.08%, SiO 2 22.55%, CaO 26.84%, TFe 1.16%;

[0039] 3. One-stage leaching

[0040] Take 900 grams of the above-mentioned ground titanium-containing blast furnace slag for one stage leaching with 5% mass concentration sulfuric acid, the amount of sulfuric acid is 1.0 times the theoretical amount, and react at normal pressure and 90°C for 60 minutes. The original slag contains 50.1% TiO 2 , 100% Al 2 O 3 And 69.1% MgO entered the leaching s...

Embodiment 2

[0048] The process flow of this embodiment is as image 3 As shown, the process steps are as follows:

[0049] 1. Water quenching

[0050] Spray the molten titanium-containing blast furnace slag with water at 30°C and quickly cool it to 60°C;

[0051] 2. Grinding

[0052] Grind the titanium-containing blast furnace slag after water quenching to 0.10~0.15mm, and the content of each component is TiO 2 22.49%, Al 2 O 3 13.69%, MgO 7.08%, SiO 2 22.55%, CaO 26.84%, TFe 1.16%;

[0053] 3. One stage leaching

[0054] Take 300 grams of the above-mentioned ground titanium-containing blast furnace slag and use the waste sulfuric acid produced by the hydrolysis process of pigment-grade titanium dioxide in Example 1 to perform one-stage leaching. The amount of sulfuric acid is 0.8 times the theoretical amount. Reaction at 70℃ for 90min, 46.6% TiO in the original slag 2 , 98.9% Al 2 O 3 And 63.7% MgO into the first leaching solution;

[0055] 4. Two-stage grinding and immersion

[0056] The lea...

Embodiment 3

[0062] The process flow of this embodiment is as image 3 As shown, the process steps are as follows:

[0063] 1. Water quenching

[0064] Spray the molten titanium-containing blast furnace slag with water at 20°C and quickly cool it to 40°C;

[0065] 2. Grinding

[0066] Grind the titanium-containing blast furnace slag after water quenching to 0.076~0.10mm, and the content of each component is TiO 2 22.49%, Al 2 O 3 13.69%, MgO 7.08%, SiO 2 22.55%, CaO 26.84%, TFe 1.16%;

[0067] 3. One stage leaching

[0068] Take 300 grams of the above-mentioned ground titanium-containing blast furnace slag and use the waste sulfuric acid produced by the hydrolysis process of pigment-grade titanium dioxide in Example 2 to perform a one-stage leaching. The amount of sulfuric acid is 0.8 times the theoretical amount. Reaction at 70℃ for 90min, 46.6% TiO in the original slag 2 , 98.9% Al 2 O 3 And 63.7% MgO into the first leaching solution;

[0069] 4. Two-stage grinding and immersion

[0070] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com