Spark plug with increased durability

A technology of spark plugs and ceramic insulators, applied in the field of spark plugs, can solve the problems of broken ceramic insulators, cracks, damaged wire covers, and more expensive pulling out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

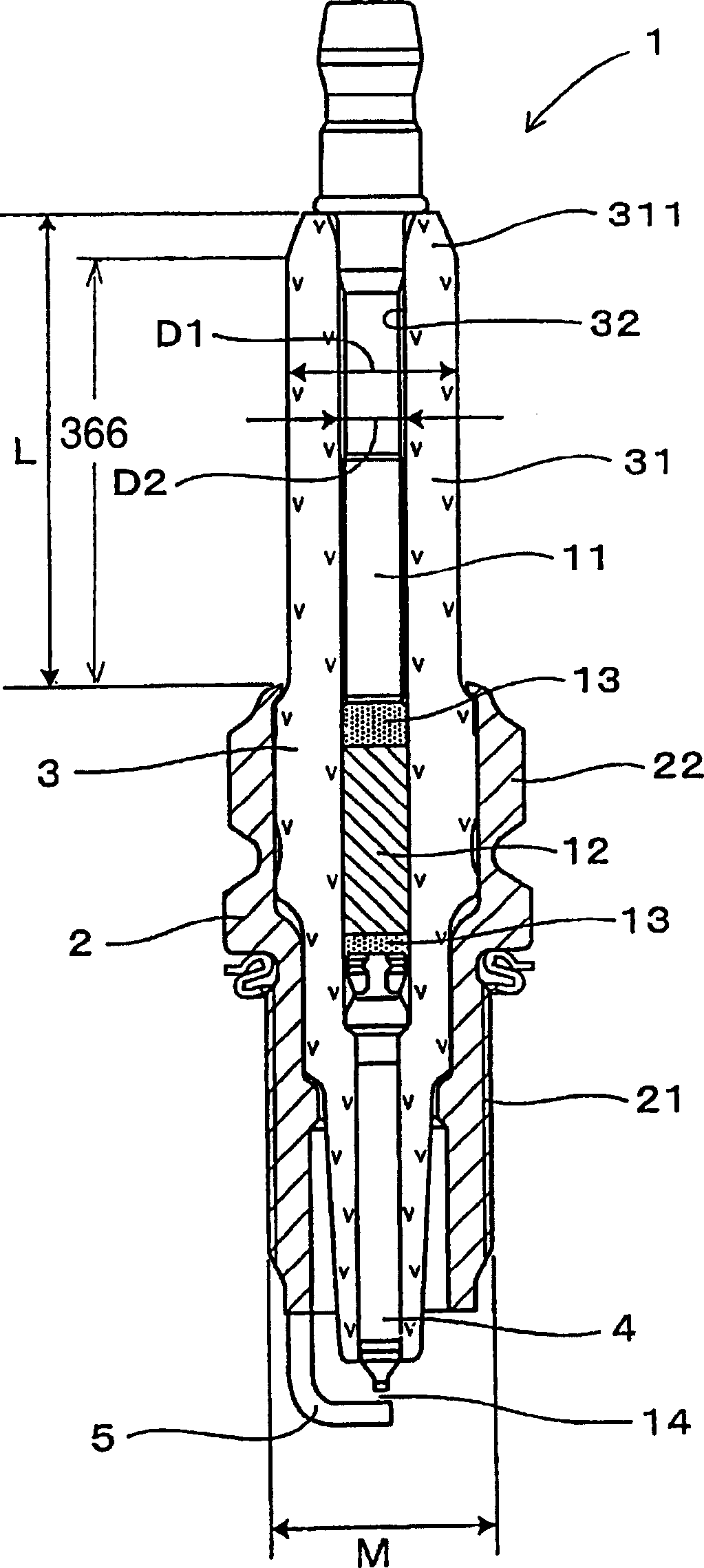

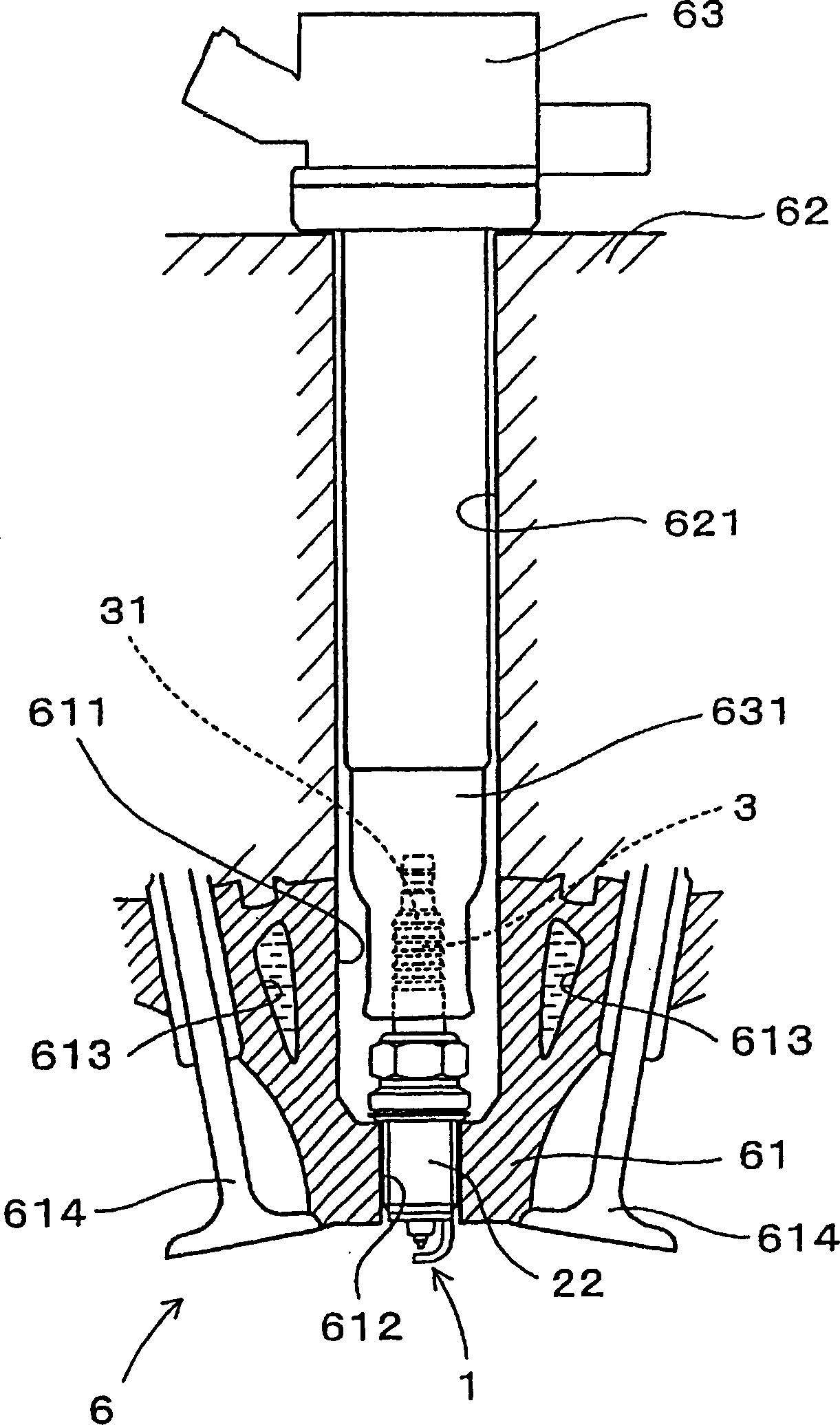

[0034] Referring now to the accompanying drawings, especially figure 1 , which shows a spark plug for an automotive internal combustion engine according to a first embodiment of the present invention.

[0035]The spark plug 1 roughly includes a hollow cylindrical metal shell 2 , a ceramic insulator 3 , a center electrode 4 and a ground electrode 5 . The ceramic insulator 3 is held within the metal case 2 to have an insulator head 31 extending outside the metal case 2 toward the base end side (ie, the upper portion as viewed in the drawing) of the spark plug 1 . The center electrode 4 is held in a center hole 32 formed in the ceramic insulator 3 . The ground electrode 5 extends from the metal casing 2 and faces the center electrode 4 through a spark discharge gap 14 .

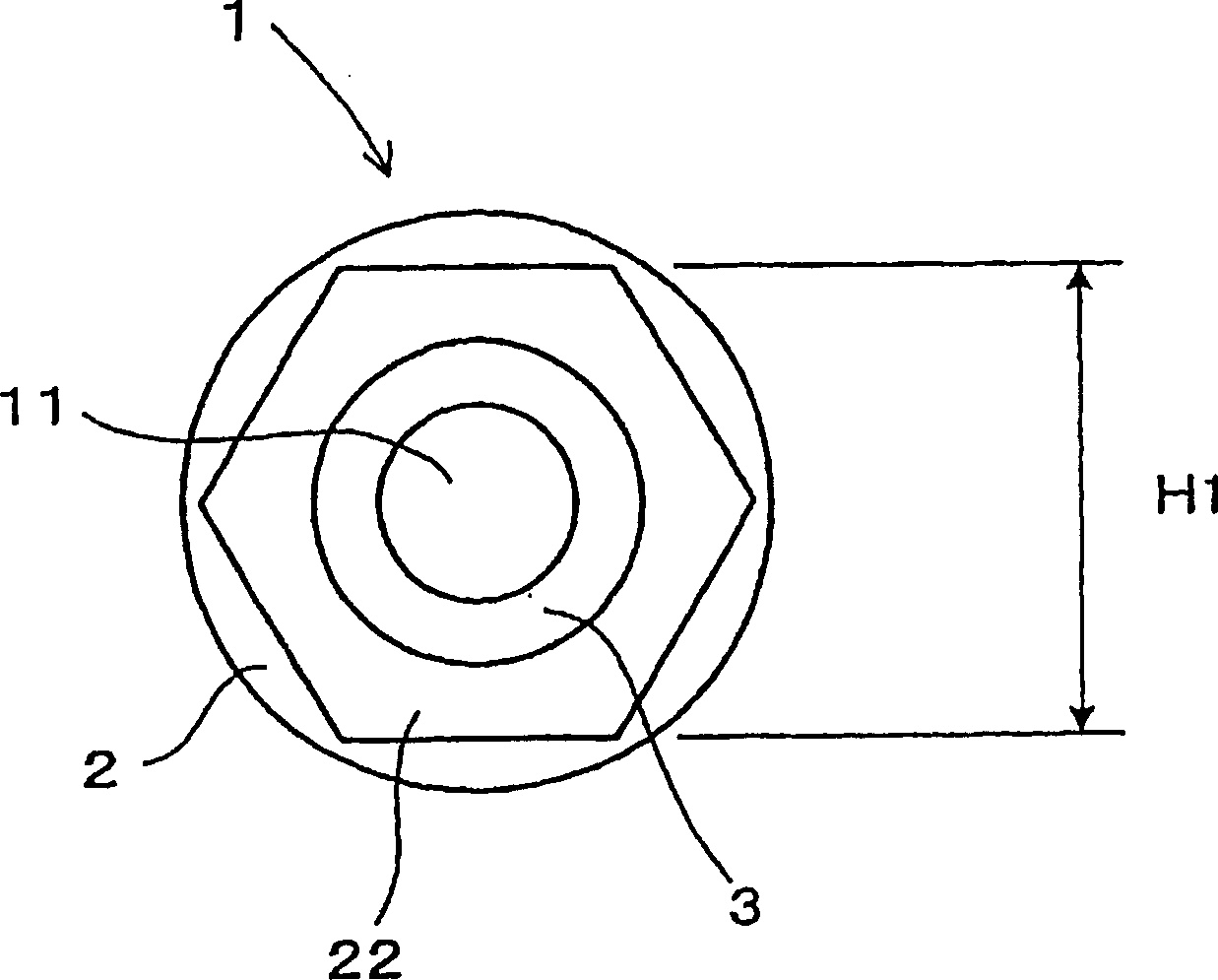

[0036] The metal shell 2 has a thread 21 and a hexagon head 22; the thread 21 is used for installation in the internal combustion engine, and a wrench will be fitted on the hexagon head 22 to install or remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com