Production of toughened and reinforced tungsten carbide composite material with non-stablized yttrium jargonia

A tungsten carbide composite material, an unsteady state technology, applied in the field of powder metallurgy industry, can solve problems such as rust spots, achieve the effects of improved bending strength and impact toughness, obvious refinement, and reasonable internal tissue composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

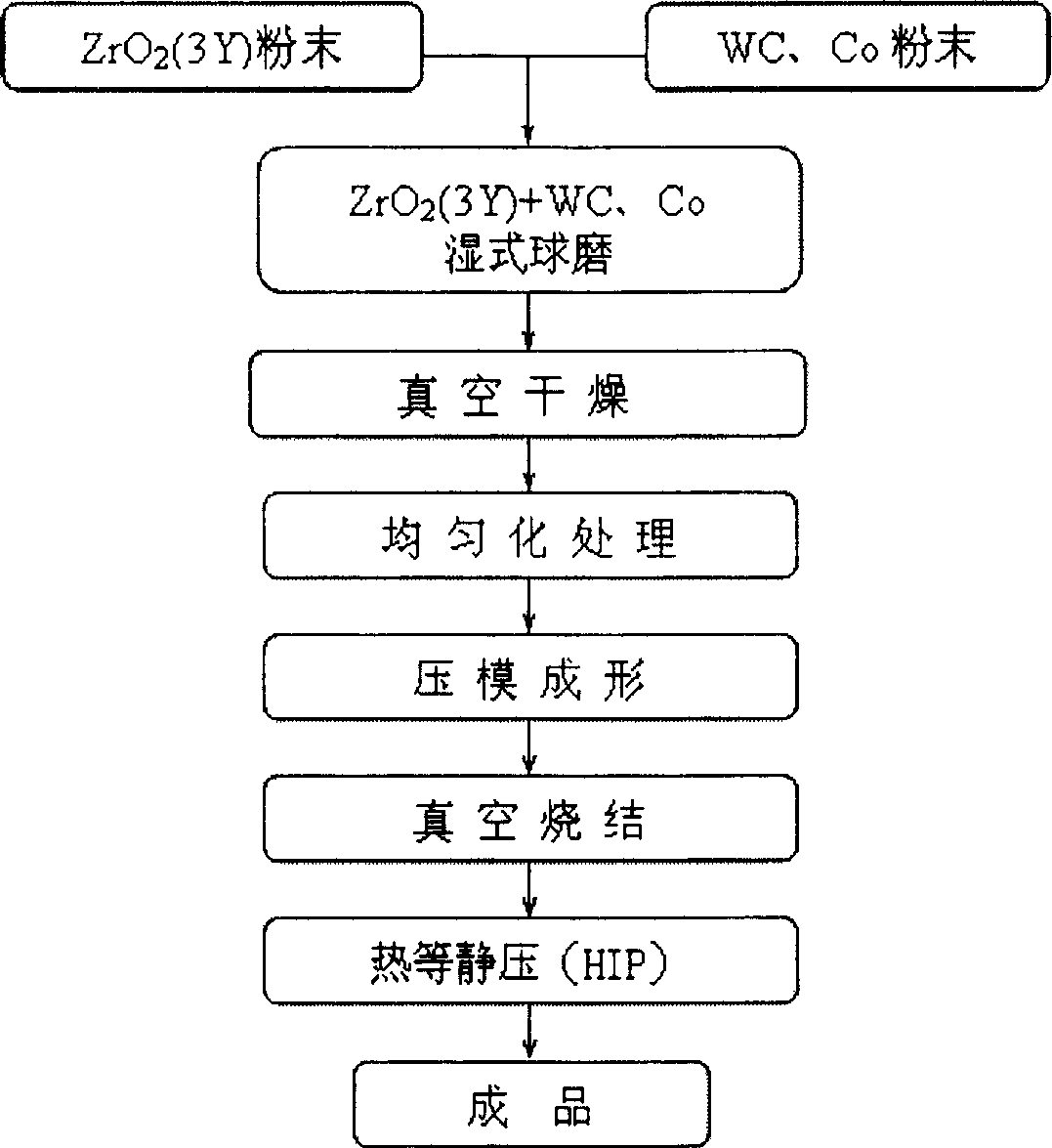

Method used

Image

Examples

Embodiment Construction

[0015] 1) The average particle size of raw material WC powder is 4.03 μm, the average particle size of Co powder is 1.63 μm, ZrO 2 Powder average particle size (D 50 ) is 0.65 μm. Formula weighing WC powder 29Kg, Co powder 7Kg and ZrO 2 Powder 4Kg, WC powder, Co powder and ZrO 2 The powder was mixed in a ball mill for 40 hours by means of wet ball milling. Then, adopt vacuum sintering process (vacuum degree is 300 Pa): heating from room temperature to the end of sintering for 14 hours, the final sintering temperature is 1380° C., and the holding time is 45 minutes. After sintering in a vacuum furnace, a densification sintering process is carried out with hot isostatic pressing equipment, using N 2 Air is used as the pressurized medium, and the pressurization is 3.5MPa.

[0016] 2) The average particle size of raw material WC powder is 4.03 μm, the average particle size of Co powder is 1.63 μm, ZrO 2 Powder average particle size (D 50 ) is 0.65 μm. Formula weighing WC p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com