Pyroelectric unit infrared detector and production thereof

A pyroelectric infrared and detector technology, which is applied to thermoelectric devices with thermal changes in dielectric constant, electrical radiation detectors, etc. Electric coefficient, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

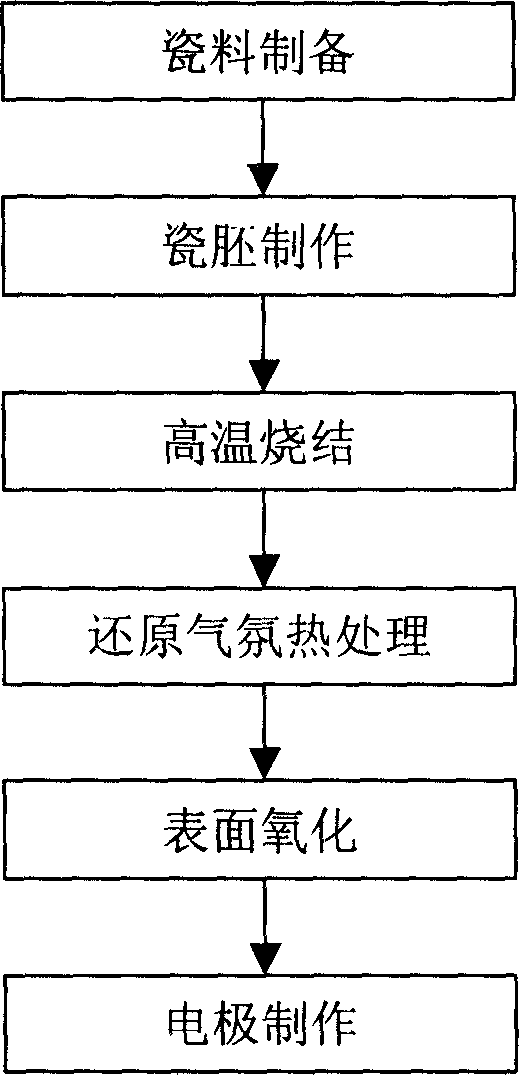

[0027] After adding 0.5wt% Nd 2 o 3 , 1.0 wt% CeO 2 and 0.1wt% MnO 2 of (Ba 0.7 Sr 0.3 )TiO 3 Porcelain ceramic material, the diameter φ = 3.8mm, thickness d = 0.20mm porcelain pieces obtained by extrusion process, the porcelain pieces are sintered in the air at 1360°C, and then heat treated in a reducing atmosphere at 1000°C-1100°C for 1-2 hours , can obtain semiconducting ceramics with resistivity less than 2Ω·cm, semiconducting ceramics are properly oxidized in air at 900℃~1000℃, and under the action of 10v bias, the pyroelectric coefficient can be obtained greater than 2× 10 -7 C / cm 2 k pyroelectric infrared detector material, the typical dynamic pyroelectric voltage response curve of this material is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com