Device and method for preparing solid thin-membrane lithium battery by in-situ deposition

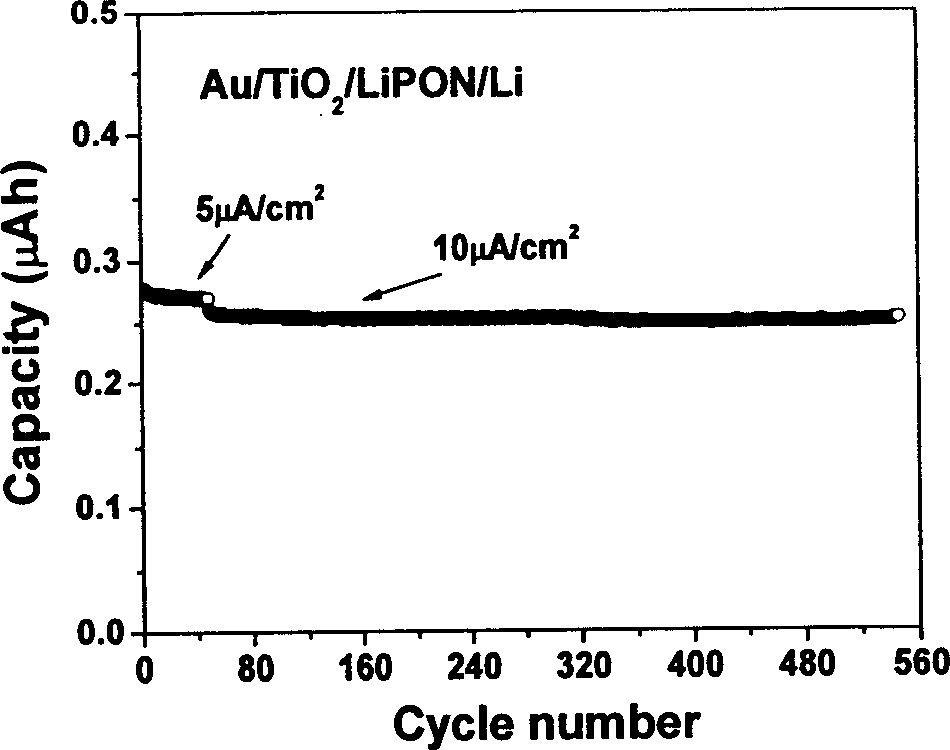

An in-situ deposition, all-solid-state technology, applied in the field of electrochemistry, can solve the problems of interface contamination and mutual contamination between materials of all-solid-state thin-film lithium batteries, and achieve the effect of small capacity decay performance, small interface resistance, and avoiding mutual contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

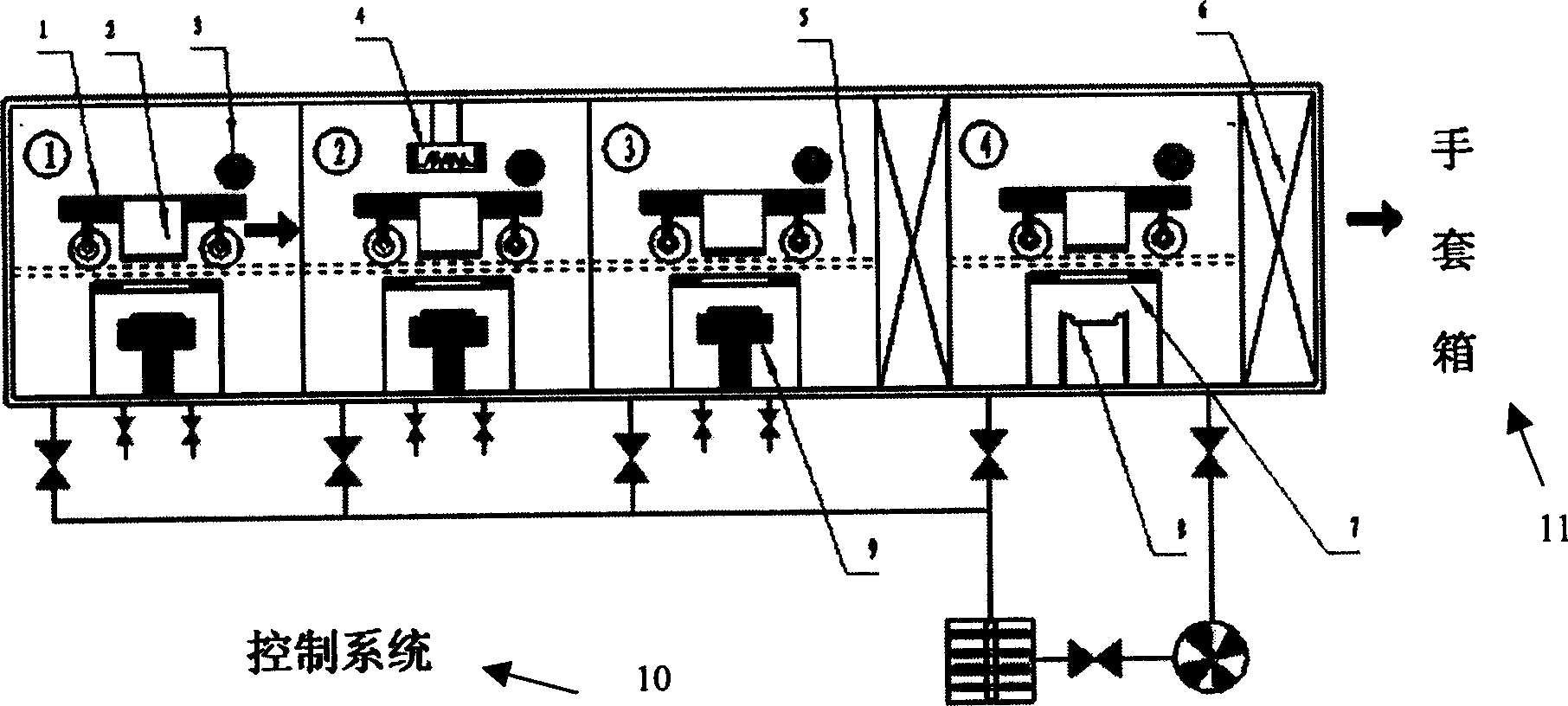

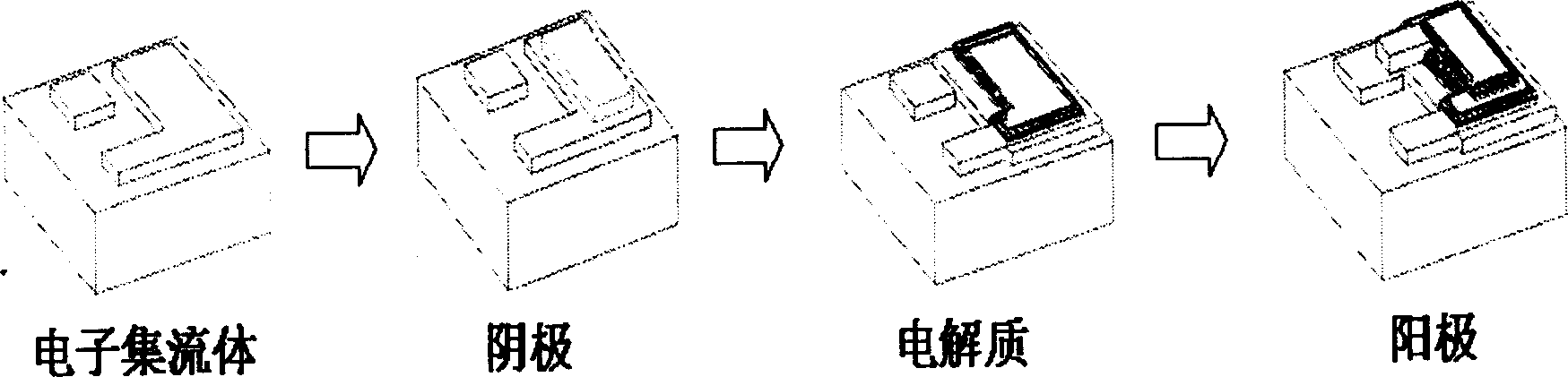

[0024] The preparation sequence and graphics of each layer of thin film in an all-solid-state thin-film lithium battery are as follows: figure 2 shown.

[0025] The preparation of the electronic current collector thin film adopts metal Pt (or other suitable metals, such as: Au, Ti, V, etc.) fluid film. The sputtering conditions are: the background pressure of the deposition chamber reaches 1×10 -3 After Pa, the control system (10) moves the transfer trolley 1 to the DC sputtering deposition chamber ①, and automatically or manually controls the mask of the deposition chamber to rise to a distance less than 3mm from the substrate (such as 0.1-3mm) ), the distance from the target to the substrate is 4-8cm; the target should be pre-sputtered for 30-60min before depositing the film, the sputtering atmosphere is pure argon, the working pressure is 0.5-2.5Pa, and the deposition power is 30-150W. The substrate can be a ceramic sheet, a quartz sheet, a glass sheet or a silicon sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com