High-purity trimethylaluminum and purification method of crude trimethylaluminum

A technology of crude trimethylaluminum and trimethylaluminum, applied in chemical instruments and methods, compounds containing elements of group 3/13 of the periodic table, organic chemistry, etc., can solve complex facilities, heavy operations, and expensive chemicals and other issues to achieve the effect of cost recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

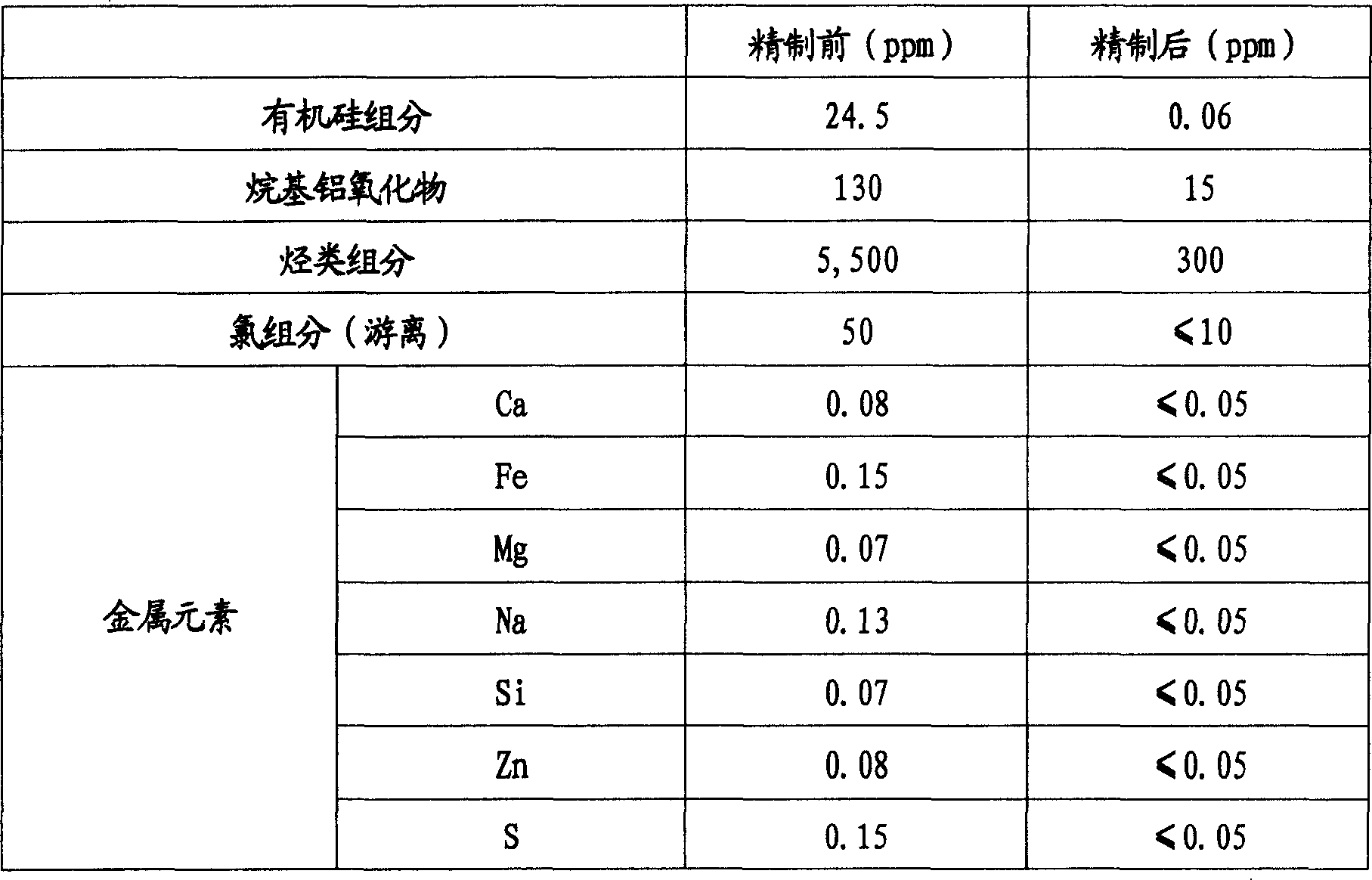

Embodiment 1

[0044] A still pot made of SUS with stirring and a packed column corresponding to 25 trays was thoroughly cleaned, then purged with helium, and then crude trimethylaluminum (100 parts by weight) was added. Commercially available sodium metal (5 parts by weight) was charged to the still and dissolved in crude trimethylaluminum at ambient pressure.

[0045] Subsequently, total reflux was performed for 2 hours. During this period, the temperature of the condenser is controlled to be 30°C lower than the top temperature of the tower, and at the same time, high-purity inert gas is introduced into the condenser at an appropriate flow rate to avoid retention of low-boiling impurities and concentrate low-boiling impurities at the top of the tower. Thereafter, distillation was carried out at a reflux ratio R=40, whereby 40% of the initial fraction was withdrawn. The distillation was then continued at a reflux ratio of 15, so that 45% of the main fraction was withdrawn. The bottom prod...

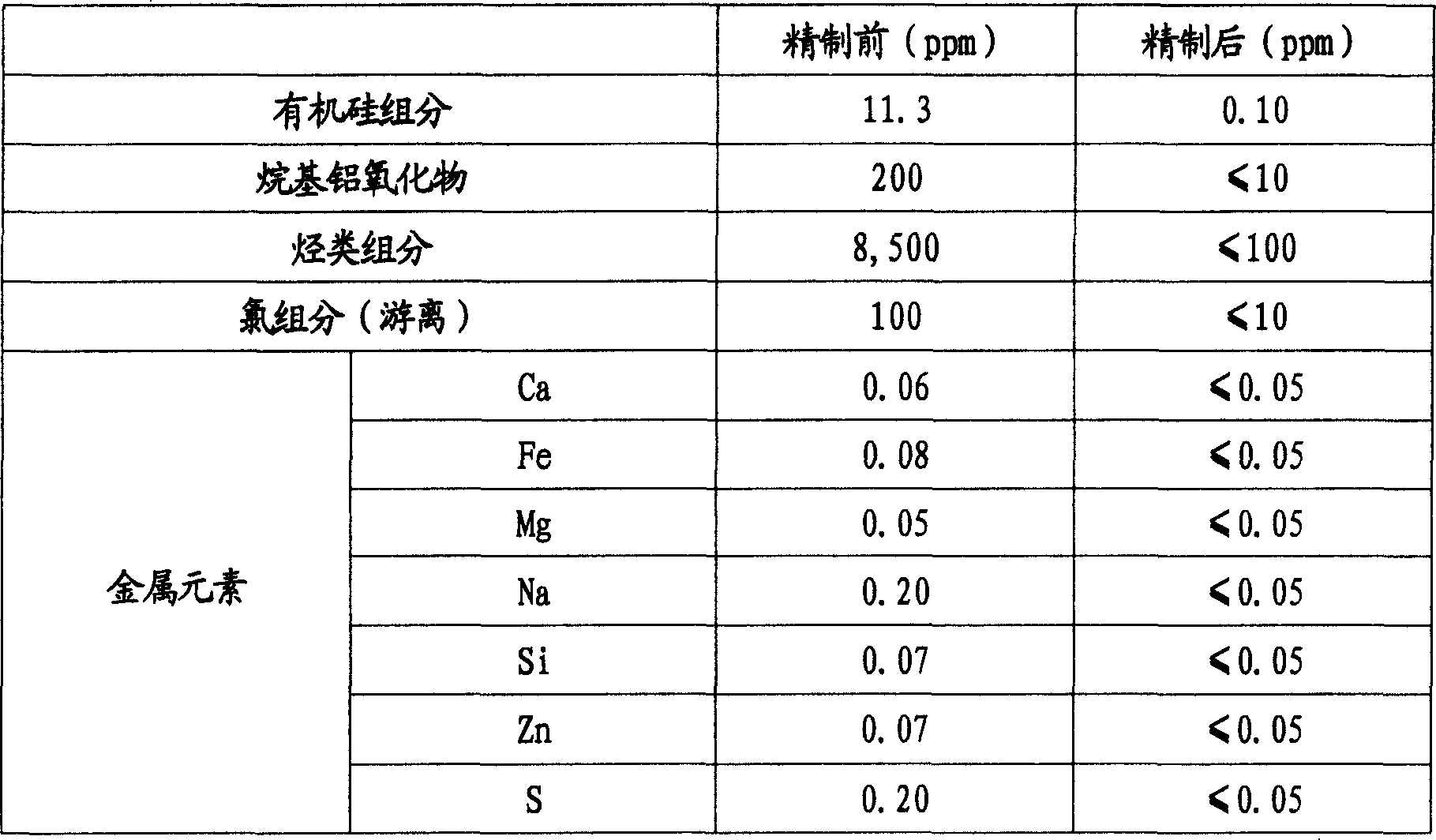

Embodiment 2

[0049] According to the same method in Example 1, different batches of crude trimethylaluminum were refined twice, and according to the measurement results of the concentration of organic silicon components in trimethylaluminum (main fraction, 35%), it was found that the concentration was 0.1 ppm. The analysis results of the main fraction are listed in Table 2.

[0050] Table 2

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com