Valve control type lead acid accumulator for metro vehicle

A lead-acid battery, valve-controlled technology, applied in lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction and other directions, can solve the problems of high price, high operating cost, high cost of alkaline nickel-cadmium Runaway control, avoidance of islands, effects of weight and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation

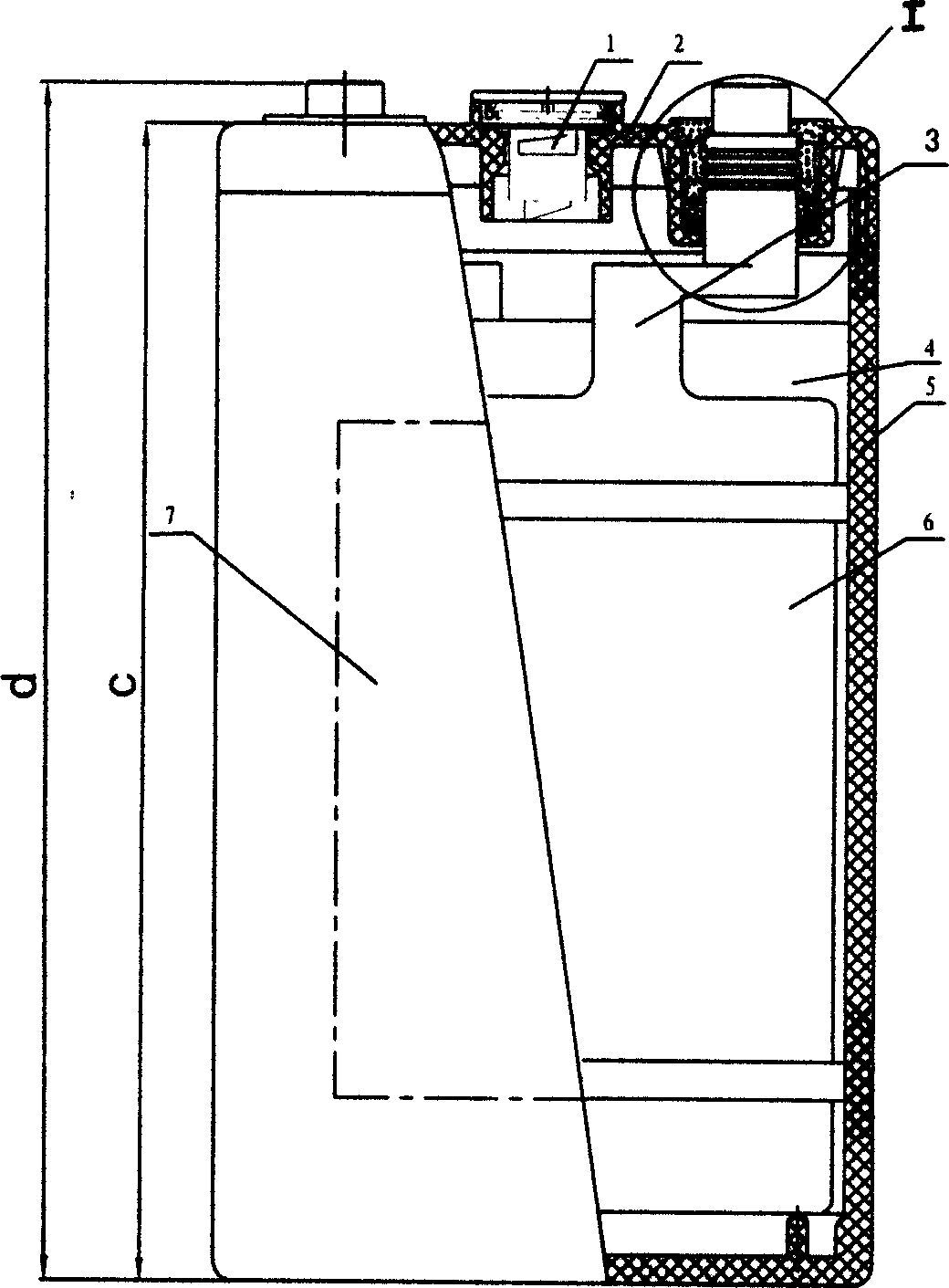

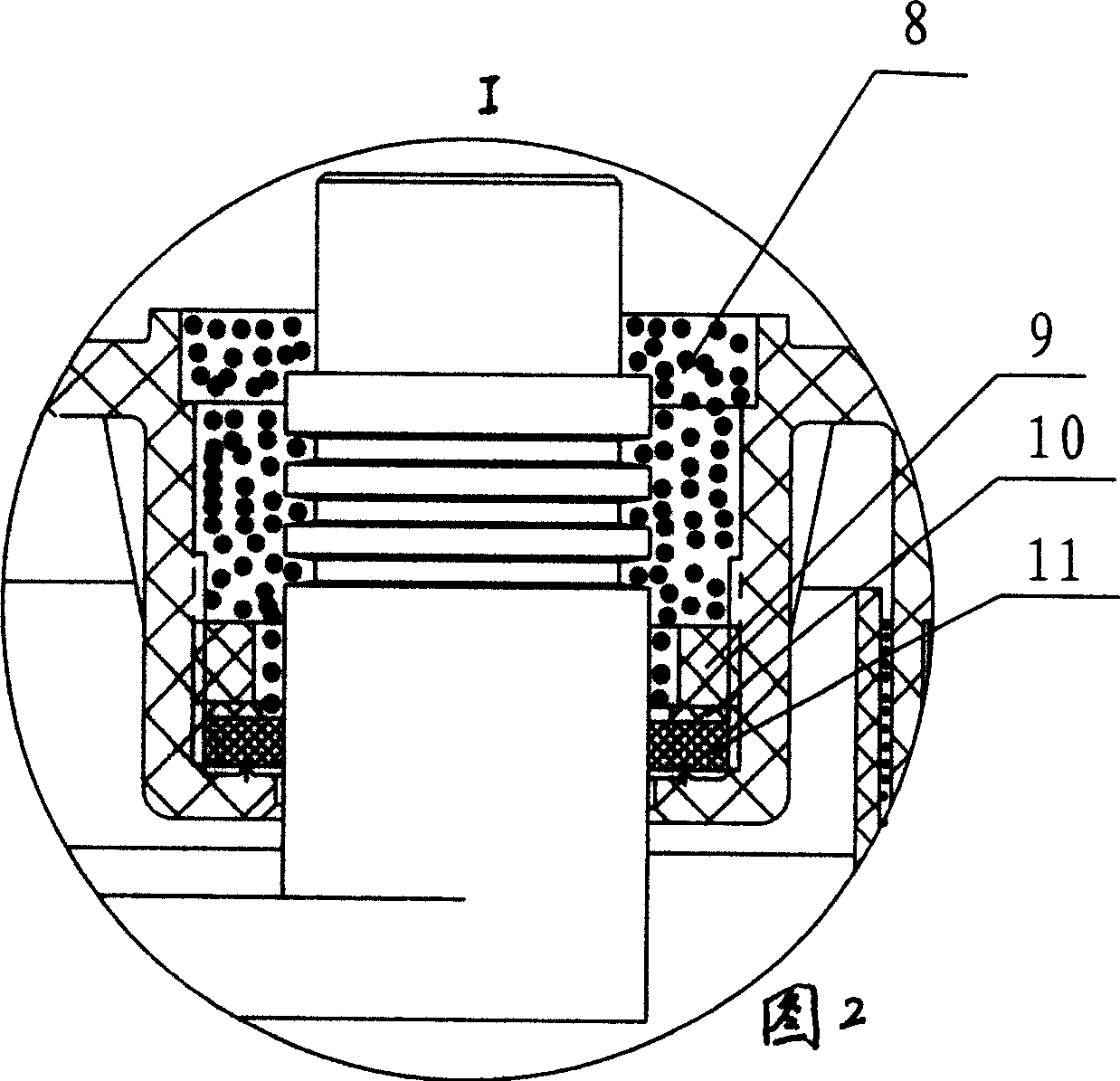

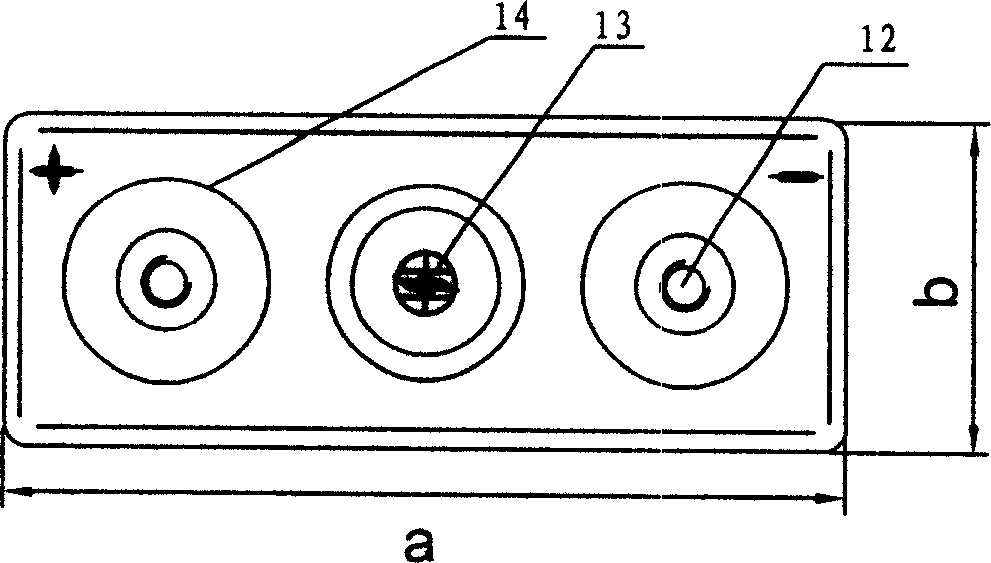

[0017] see Figure 1-4 , the present invention is composed of a battery tank 5, a battery cover 2, positive and negative plates 6, a glass fiber separator 7, a colloidal electrolyte 4, a safety explosion-proof valve 1, a battery lead-out terminal 12 and a bus bar 3, etc., the positive and negative electrodes Plates 6 are separated by glass fiber separators 7, stacked in sequence and placed in the battery tank 5 under pressure. The tab 15 of the pole plate 6 is connected to the battery lead-out terminal 12 by the bus bar 3, and the tank cover is all made of flame-retardant ABS engineering plastics, the seal between the tank covers is bonded by heat sealing, and the double sealing method is used between the battery lead-out terminal 12 and the battery cover 2: that is, the bottom layer uses a plastic nut 9, and the acid-resistant and aging-resistant silicon is pressed tightly through the plastic gasket 10. Fluorine rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com