Solid liquid separation machine

A solid-liquid separator and casing technology, applied in solid separation, grading, presses, etc., can solve the problems of unrecyclable feces, waste of organic fertilizer resources, high project investment costs, etc., to achieve simple structure, avoid pollution, The effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

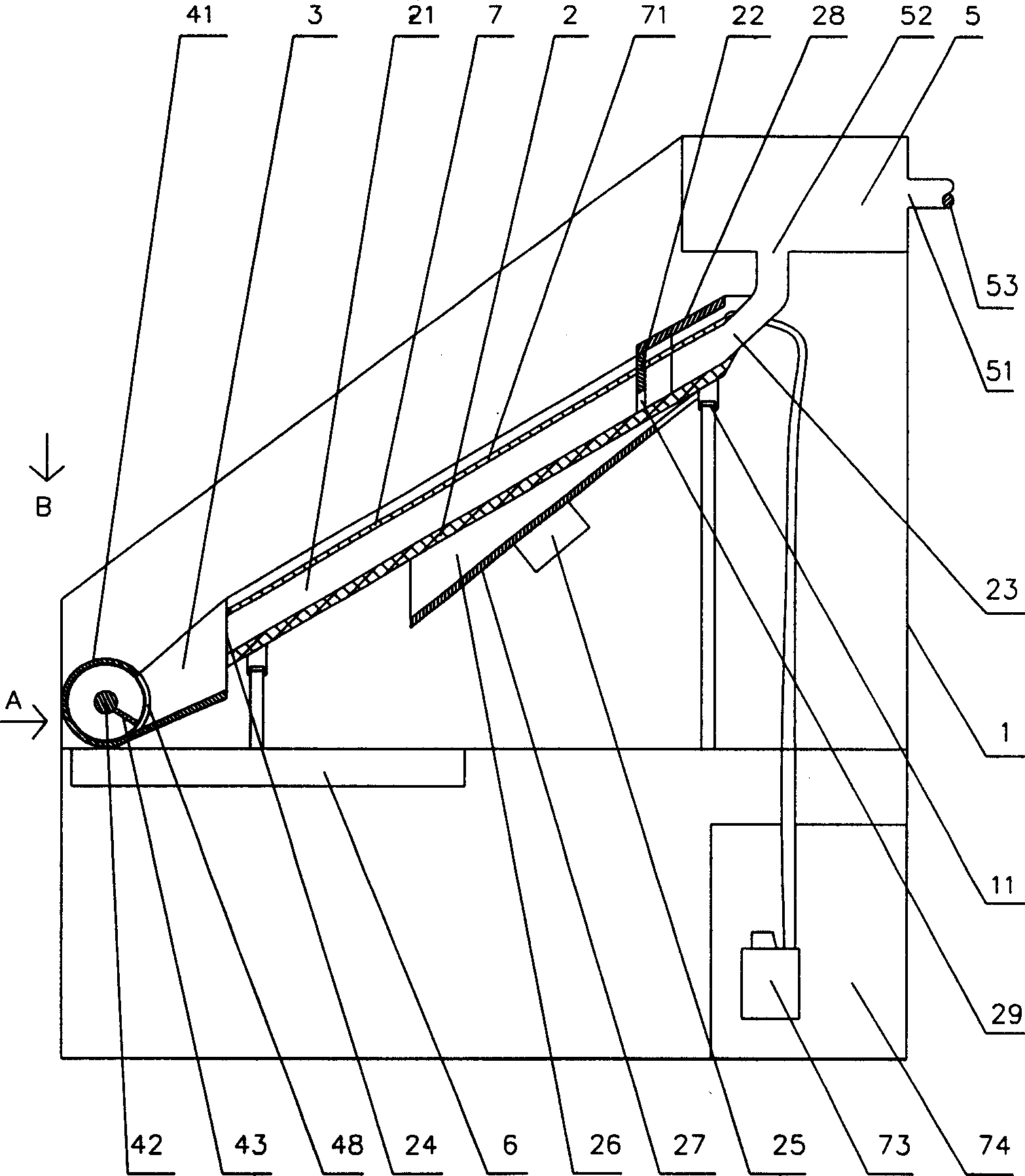

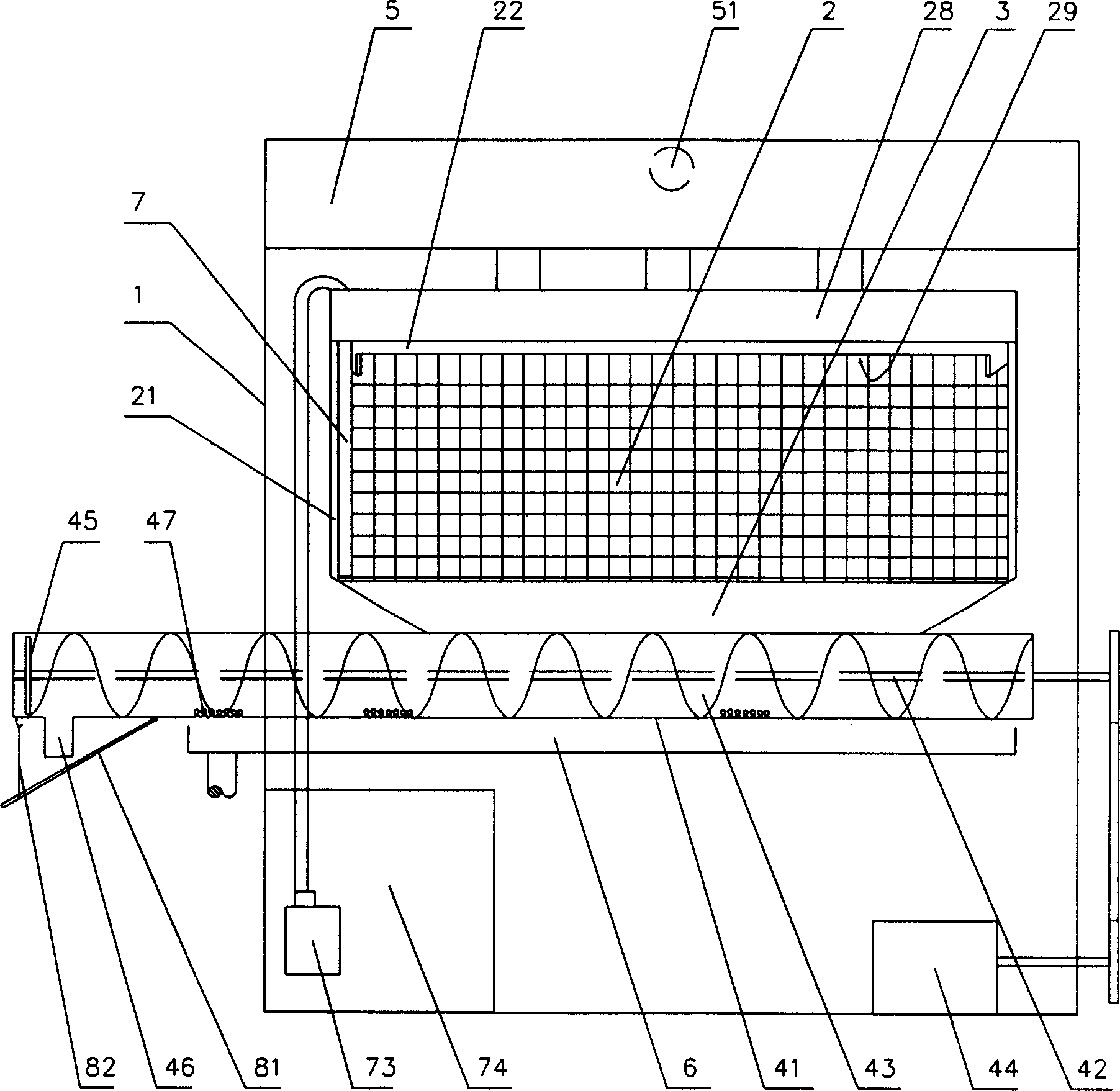

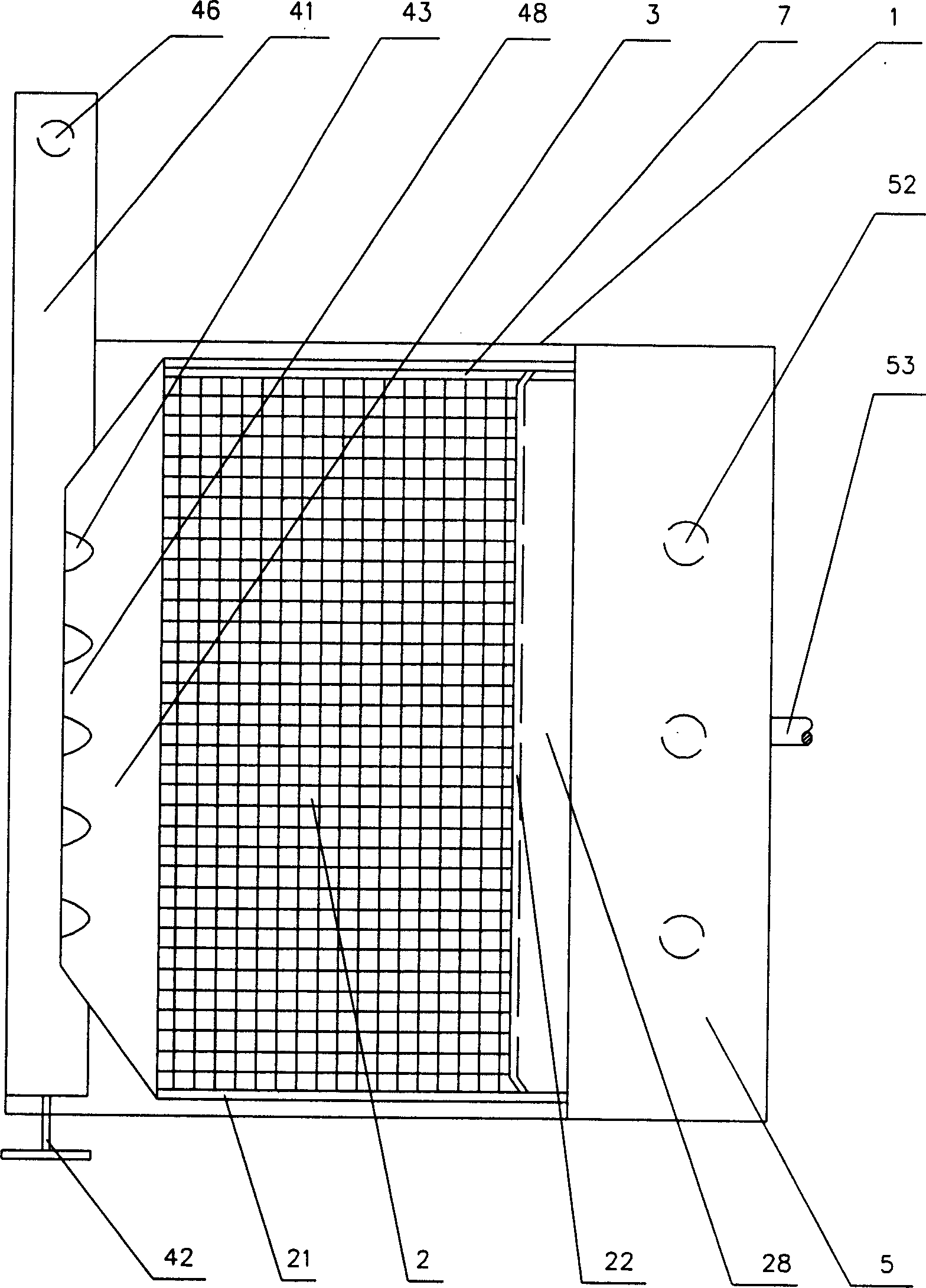

[0024] Refer to attached drawings. As can be seen from the drawings, the frame 1 is provided with an inclined vibrating screen 2, side plates 21 are respectively fixed on both sides of the vibrating screen 2, a plurality of dirt inlets 23 are arranged at the entrance of the upper end, and The slag discharge port 24 has a sewage receiving plate 6 fixed below it; the upstream part of the vibrating screen 2 is laterally fixed with a transverse partition 22 with the same height as the side plate 21, and the two ends of the transverse partition 28 are folded upward and They are fixedly connected to the side plates 21 of the vibrating screen respectively, the lower surfaces of the folded parts at both ends are close to the upper surface of the vibrating screen, and there is a slag clearance gap 29 between the lower surface of the middle part and the vibrating screen. A detachable sealing plate 22 is fixed above the vibrating screen 2 between the diaphragm 22 and the dirt inlet 23 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com