Accessory ingredient for viscous crude oil exploitation, its preparation and application

A technology of heavy oil and additives, applied in the direction of chemical instruments and methods, drilling compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

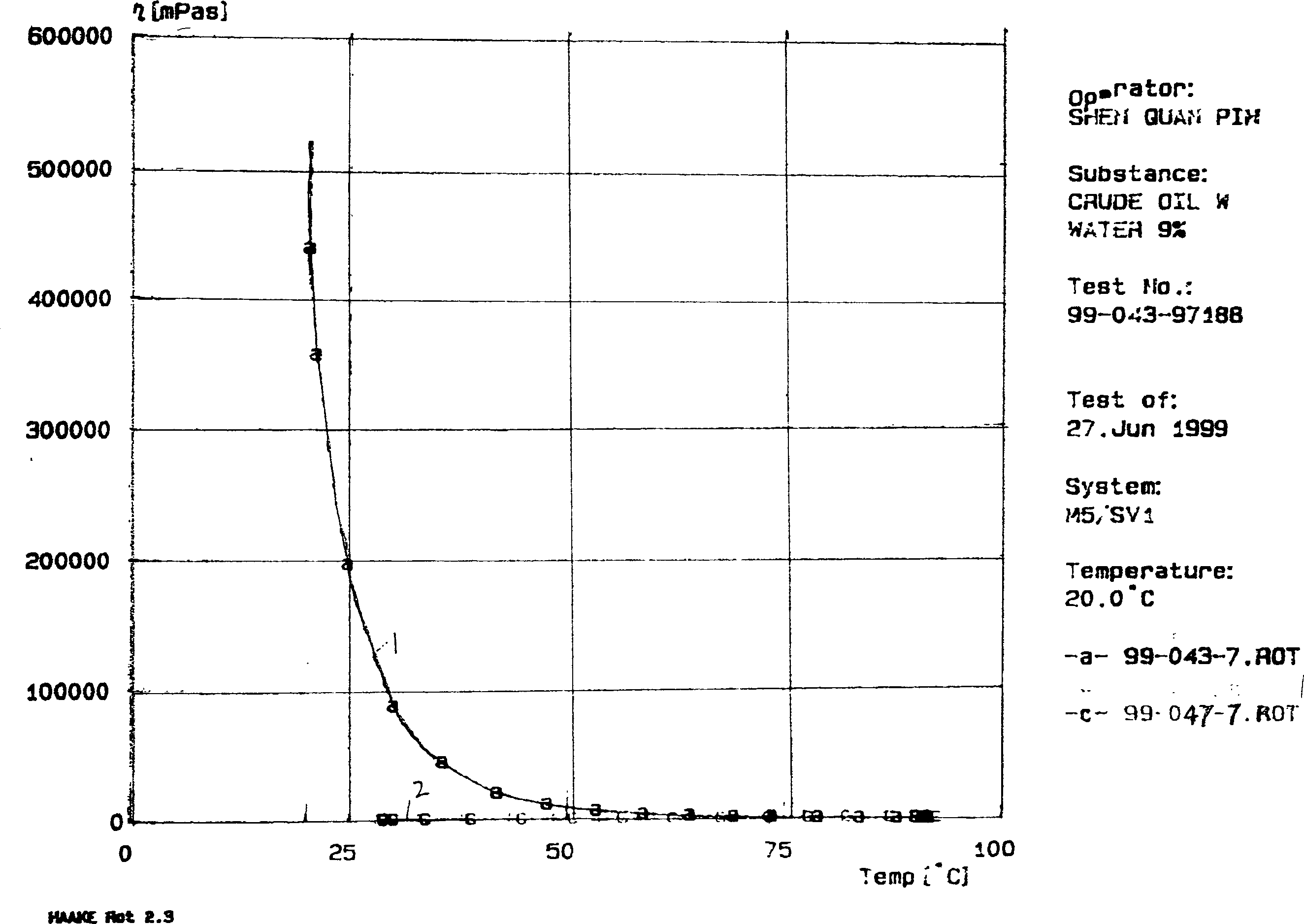

Image

Examples

Embodiment 1

[0015] Embodiment 1: (see figure) a kind of heavy oil recovery aid is characterized in that its formula and content are: amphoteric surfactant 10%, polyethylene polyamine block polyether 8%, phenolic resin block polyether 10%, low molecular alcohol polyether 4%, penetrant 5%, sodium lignin 8% and water 55%.

[0016] A preparation method of the above-mentioned heavy oil production aid is characterized in that it is composed of the following steps:

[0017] (1) 10% of the above-mentioned amphoteric surfactant, 8% of polyethylene polyamine block polyether, 10% of phenolic resin block polyether and 8% of sodium lignin are put into a stirred tank, mixed and heated to 80°C, Stir until all are melted;

[0018] (2) Add 4% low-molecular alcohol polyether, 5% penetrant and 55% water to (1) and stir evenly;

[0019] (3) In (2), use the regulator citric acid to adjust the pH to 8-9, cool down to 30°C, and fill it into barrels, which is the finished product.

[0020] An application of t...

Embodiment 2

[0029] Embodiment 2: the application of the product obtained by the aforementioned method is characterized in that the above-mentioned prepared recovery aid is used for heavy oil recovery and oil well plugging removal.

[0030] Add 2% of the above-mentioned heavy oil recovery aid to 98% water to prepare an aqueous solution, and inject it into the ground at a temperature of 50-60° C. for heavy oil recovery.

[0031] Its construction process is as follows:

[0032] Firstly, select the wells that have sufficient energy in the formation and are difficult to produce due to thick oil and heavy organic deposits that cause clogging of the oil layer. The treatment fluid depends on the damage radius and degree of the oil layer, but the general treatment radius is 1-1.5m and the treatment fluid dosage is:

[0033] V=∏R 2 φh

[0034] In the formula: V-treatment liquid consumption m 3

[0035] R-treatment radius m

[0036] φ-porosity %

[0037] h-effective th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com