Grain compositions containing pre-biotic isomalto-oligosaccharides and methods of making and using same

A technology of isomalt-oligosaccharide and composition, which is applied in the field of cereal composition containing probiotic isomalt-oligosaccharide and its manufacture and application, and can solve the problems of microbial pollution, high energy cost, high risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

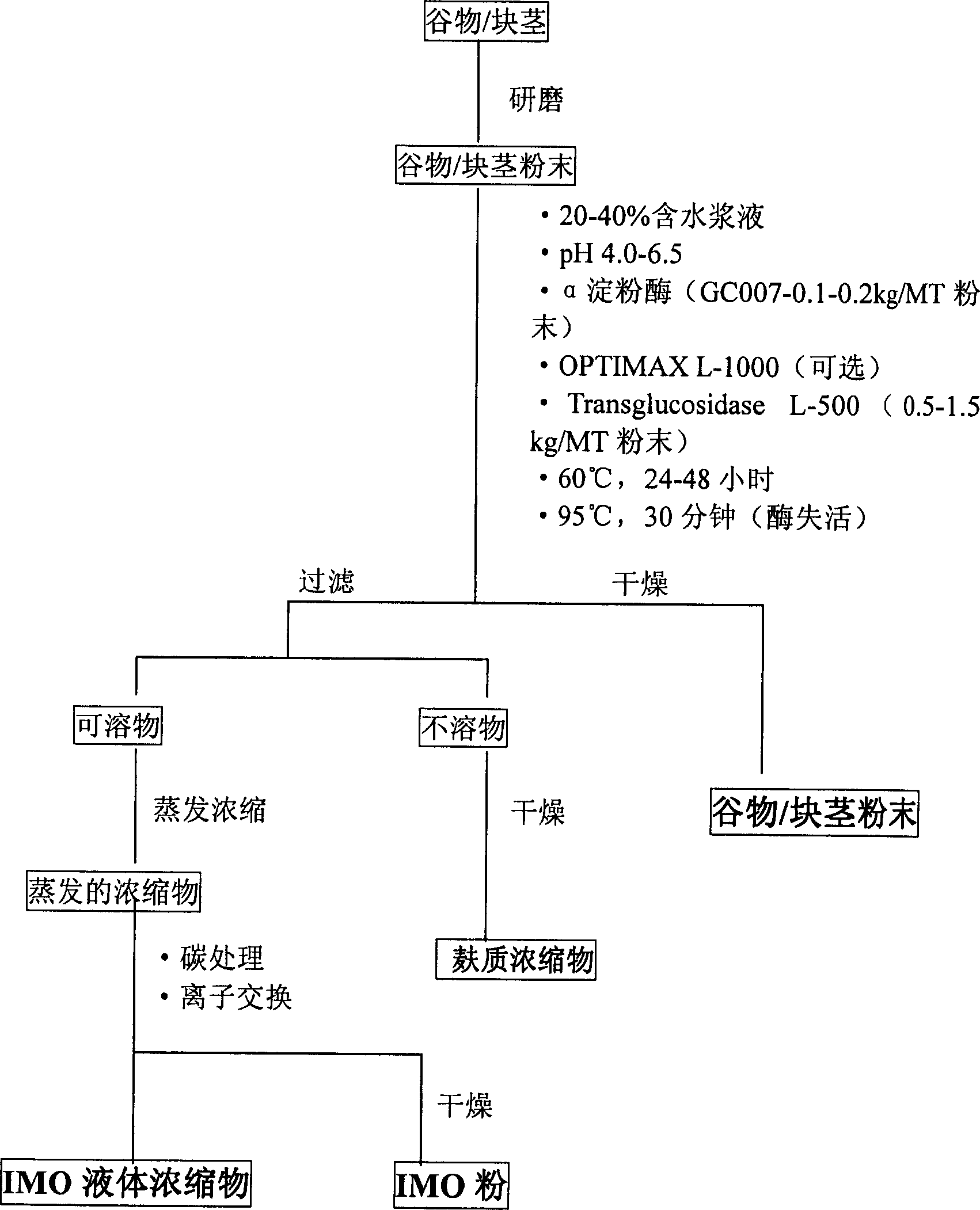

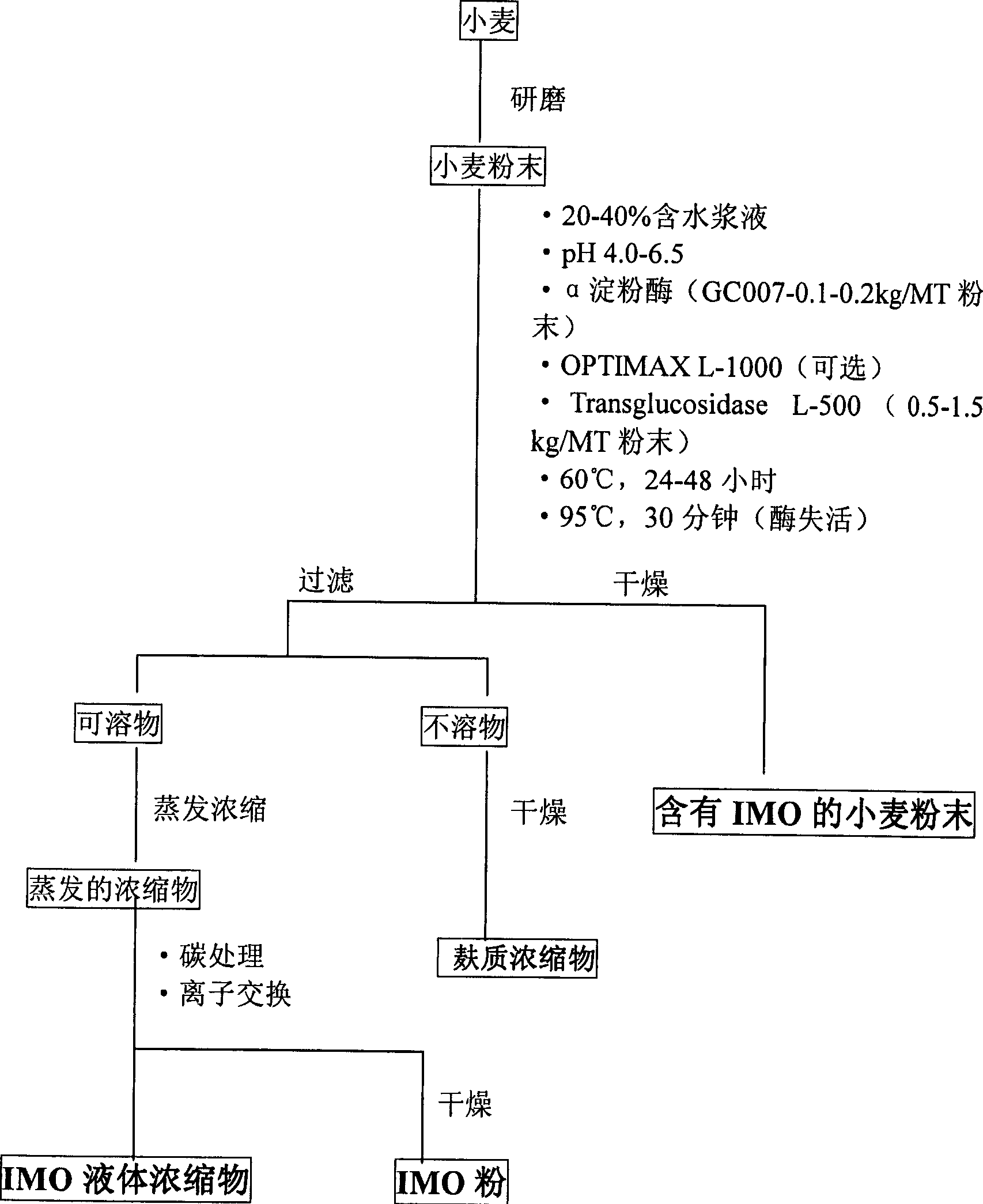

Method used

Image

Examples

Embodiment 1

[0152] Compare the α-amylase from Bacillus licheniformis (a kind of α-amylase sold by Genencor International, Palo Alto, CA, trade name is GC262SP) and the α-amylase from Bacillus stearothermophilus (by Genencor International, Palo Alto, CA). An alpha-amylase sold by CA under the trade name GC007) utilizes wheat flour for the production of maltose. 150 grams of wheat flour from a commercial retail source was suspended in 450 ml of deionized water. The suspension was stirred at room temperature for 15 minutes to mix well (pH 5.5). With 6.0N sulfuric acid (H 2 SO 4) to adjust the pH. The resulting suspension was kept in a water bath, maintained at 60°C, and stirred for uniform mixing prior to enzyme addition. Under continuous stirring at 60°C, approximately 6000 LU / g of amylase from Bacillus stearothermophilus (0.6 kg of GC007 [from Genencor International. Inc.] / metric ton (Mt.) starch dsb) and amylase from Bacillus licheniformis were added, respectively. Amylase 15,100 LU / ...

Embodiment 2

[0157] Effect of concentration of Bacillus licheniformis alpha-amylase (alpha-amylase sold by Genencor international, Palo Alto, CA under the trade name GC 007) on maltose production during incubation with wheat flour. The experimental conditions were the same as those described in Example 1. In addition, Bacillus stearothermophilus (6,000 units / gram) was added at 0.1 Kg, 0.2 Kg and 0.6 Kg / MT starch dsb. The results are summarized in Table 3.

[0158] table 3

[0159] GC007

[0160] No significant effect of different levels of alpha amylase on maltose content or on dissolved solids was observed during wheat flour incubation. Therefore, for further optimization studies, 0.1 Kg GC007 / MT starch, dsb was applied.

Embodiment 3

[0162] Suspend 150 grams of wheat flour in 450 ml of deionized water, and use 6.0N H 2 SO 4 The pH was adjusted to pH 5.00, 4.50 and 4.00. Shake the slurry well to mix evenly, and adjust the pH until it stabilizes at the specified pH value. GC007 was added to each experimental group in an amount of 0.1 Kgs / MT starch dsb and incubated at 60°C. Samples were taken at different predetermined time intervals for determination of sugar composition and brix, as described in Example 1. (Table 4).

[0163] Table 4

[0164] pH

[0165] When the pH value of the wheat flour was lowered from 5.5 during incubation, the maltose content increased and reached a maximum at pH 4.5, about 68%, followed by a decrease at pH 4.0. During starch hydrolysis using plant beta amylase, it was an unexpected result that a maltose content greater than 60% was produced without the addition of a debranching enzyme. Hydrolysis of liquefied starch by commercial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com