Method and apparatus for reducing content of ozone in waste-gas

A technology for ozone concentration and exhaust gas, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as ineffective treatment of ozone, unstable water-washing devices, etc., to solve instability defects and reduce ozone Concentration, the effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, the following preferred specific embodiments of the method and device for reducing the ozone concentration in exhaust gas are described as follows.

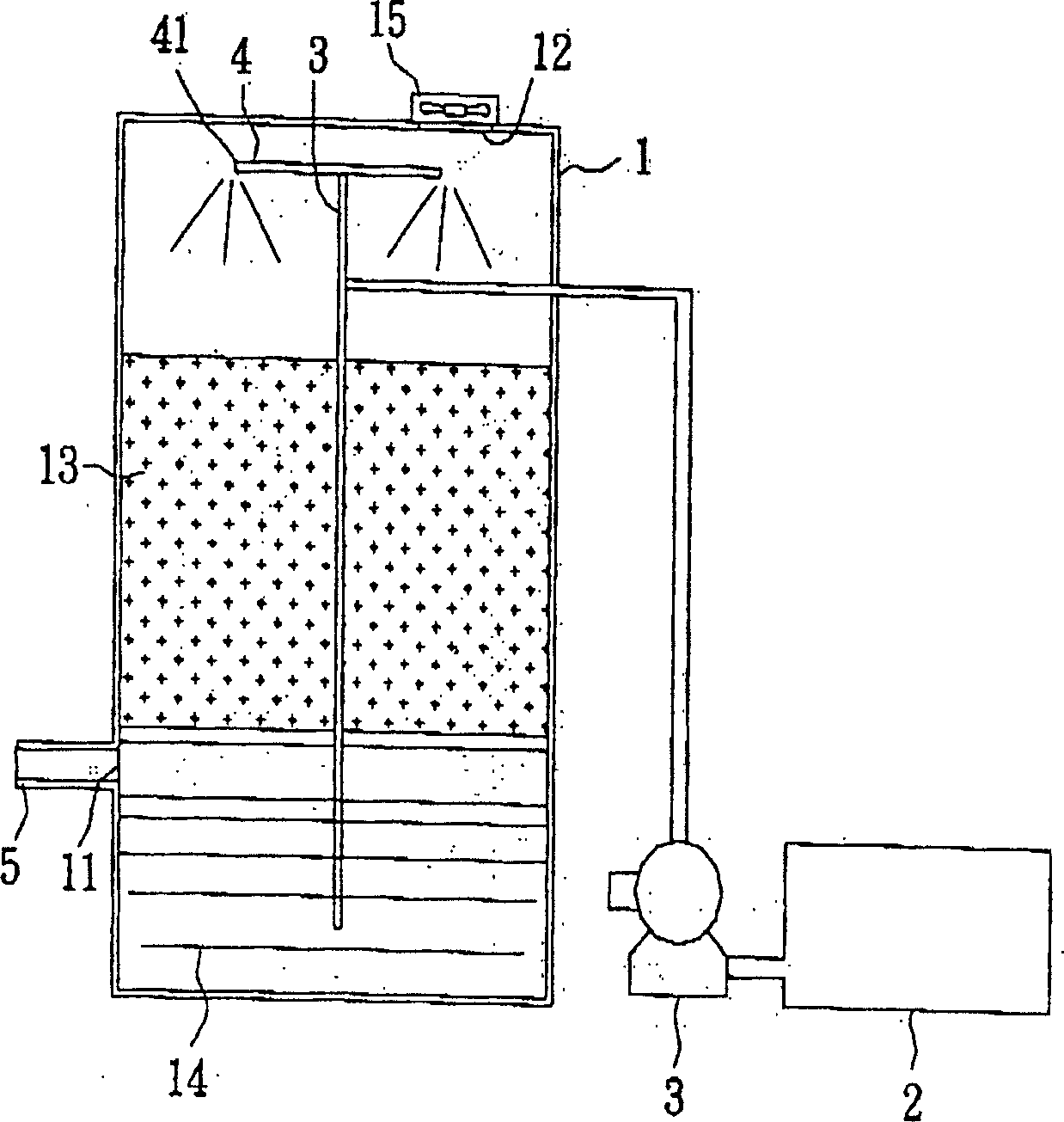

[0024] First please refer to figure 1 , is a schematic circle of the device for reducing ozone concentration in exhaust gas of the present invention. As shown in the figure, the lower end of the tank body 1 has a gas input port 11, which is connected to a pipeline 5; the upper end of the tank body 1 has a gas discharge port 12, and the gas discharge port 12 is equipped with a row of fans 15 to effectively discharge the gas; Moreover, a plurality of filler particles 13 are filled in the tank body 1 . Therefore, when the gas in the pipeline 5 is input into the tank body 1 through the gas input port 11, the gas will first pass through the gap of the filler 13, and then be discharged from the gas discharge port 12 on the tank body. On the other han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com