Determination method of effective component in aliphatic oil

The technology of an active ingredient and a determination method is applied in a field of determination of active ingredients in fatty oil, which can solve the problems of wasting organic solvents, adverse to human health, time-consuming and labor-intensive, and saves time, operation time and reagents. The effect of the solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

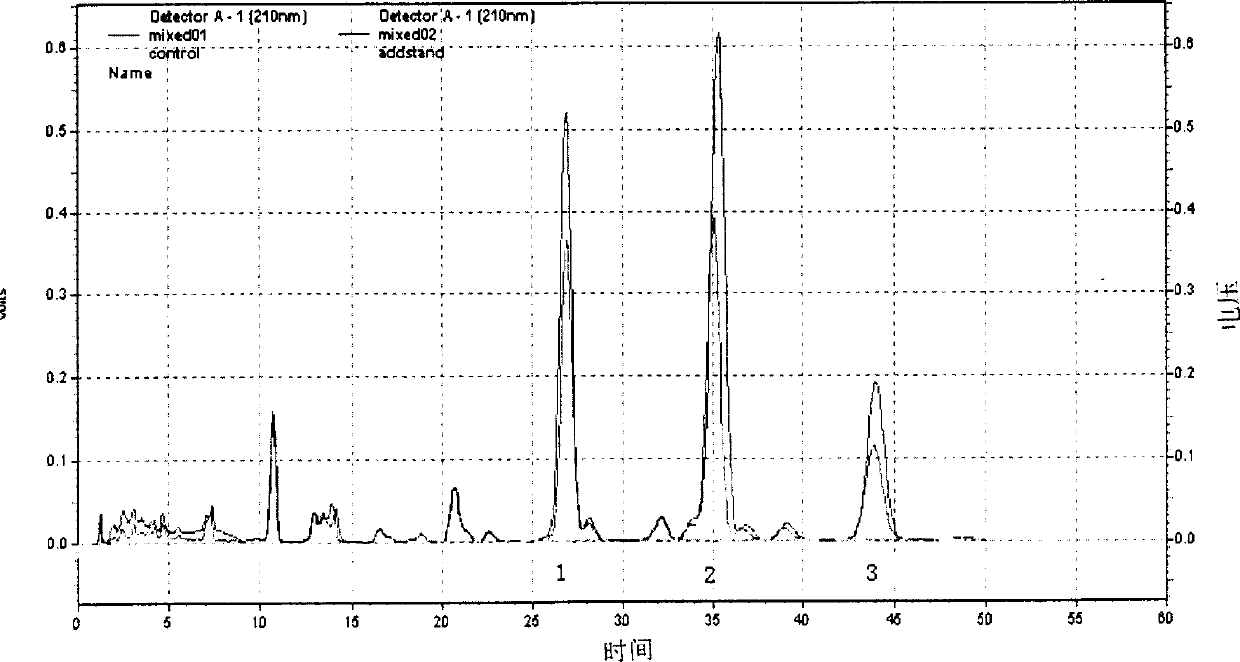

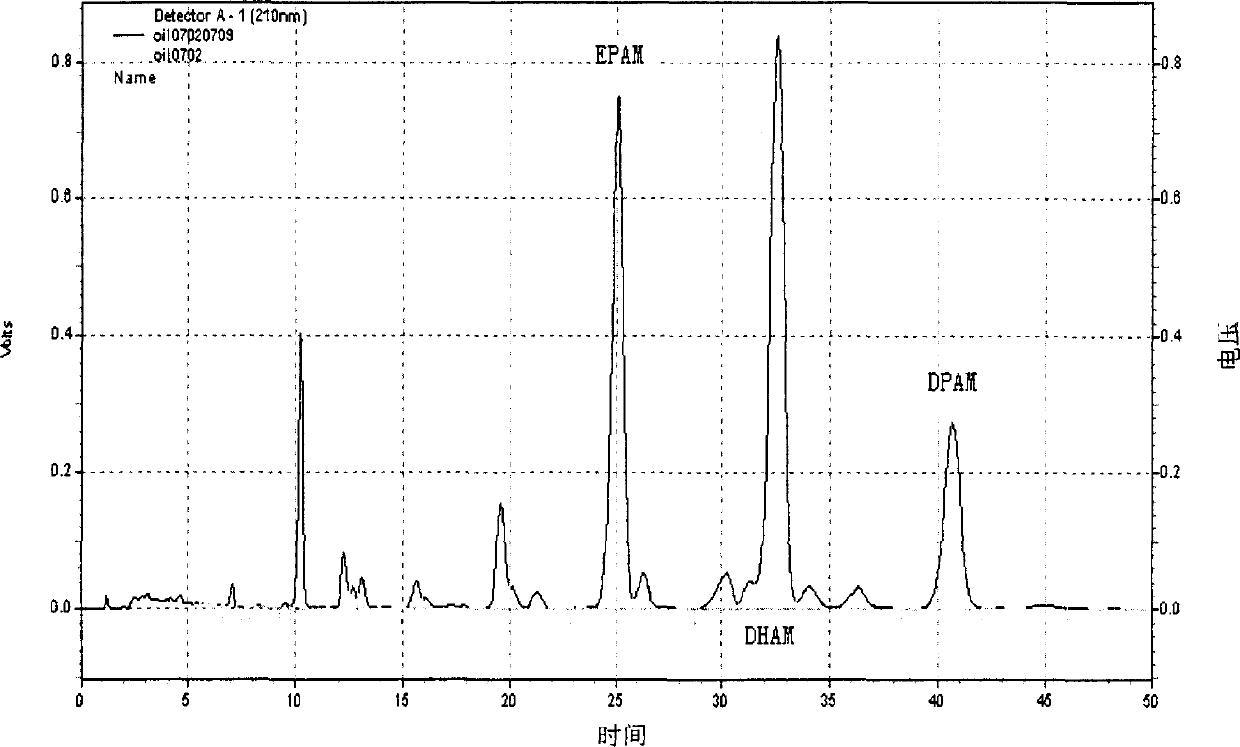

[0070] The assay method of the seal oil active ingredient described in the present embodiment, comprises the following steps:

[0071] 1) Derivatization treatment of seal oil:

[0072] Take 120 μl of seal oil, put it in a 10ml measuring bottle, add 4ml of 0.5mol / L sodium methoxide, shake well, react at room temperature for 15 minutes, until the small oil droplets completely disappear, then add 0.2ml of glacial acetic acid to terminate the reaction, and use 0.005% BHT Methanol constant volume, 0.2 μm filter membrane filtration, obtains the seal oil test solution that derivatization is processed;

[0073] 2) Get 20 μ l of the seal oil test solution after the derivatization treatment, and enter the liquid chromatograph, and the chromatographic conditions of the chromatograph are:

[0074] Chromatographic column: Lichrospher RP-18, 5μm, 100A, 4.6mm×250mm;

[0075] Mobile phase: acetonitrile: methanol: water = 7:1:2, isocratic elution;

[0076] Flow rate: 1.2ml / min;

[0077] Co...

Embodiment 2

[0083] The assay method of the seal oil active ingredient described in the present embodiment, comprises the following steps:

[0084] 1) Derivatization treatment of seal oil:

[0085] Take 80 μl of seal oil, put it in a 50ml measuring bottle, add 6ml of 0.8mol / L sodium methoxide, shake well, react at 40°C until the small oil droplets completely disappear, then add 0.3ml of glacial acetic acid to stop the reaction, and use 0.003% BHT containing Methanol constant volume, 0.2μm filter membrane filtration, obtains the seal oil test solution that derivatizes and handles;

[0086] 2) Get 30 μl of the seal oil test solution after the derivatization treatment, and enter the liquid chromatograph, and the chromatographic conditions of the chromatograph are:

[0087] Chromatographic column: LichrospherRP-18, 5μm, 100A, 4.6mm×250mm;

[0088] Mobile phase: methanol: water = 3: 2, isocratic elution;

[0089] Flow rate: 1.3ml / min;

[0090] Column temperature: 30°C;

[0091] Detection w...

Embodiment 3

[0096] The assay method of the seal oil active ingredient described in the present embodiment, comprises the following steps:

[0097] 1) Derivatization treatment of seal oil:

[0098] Take 100 μl of seal oil, put it in a 100ml measuring bottle, add 8ml of 1.0mol / L sodium methoxide, shake well, react at 50°C until the small oil droplets completely disappear, then add 0.5ml of glacial acetic acid to terminate the reaction, and use 0.001% BHT containing Methanol constant volume, 0.2μm filter membrane filtration, obtains the seal oil test solution that derivatizes and handles;

[0099] 2) Get 50 μ l of the seal oil test solution after derivatization, enter the liquid chromatograph, and the chromatographic conditions of the chromatograph are:

[0100] Chromatographic column: Waters SymmetryShield RP-18, 5μm, 100, 3.9mm×150mm;

[0101] Mobile phase: acetonitrile: methanol: water = 7:1:2, isocratic elution;

[0102] Flow rate: 1.3ml / min;

[0103] Column temperature: 15°C;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com