Active carbon fiber in hollow morphological structure, and preparation method

A technology of activated carbon fiber and morphological structure, applied in hollow filament manufacturing, fiber chemical characteristics, rayon manufacturing and other directions, can solve problems such as limited application, and achieve a wide range of applications, good formability, and good purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

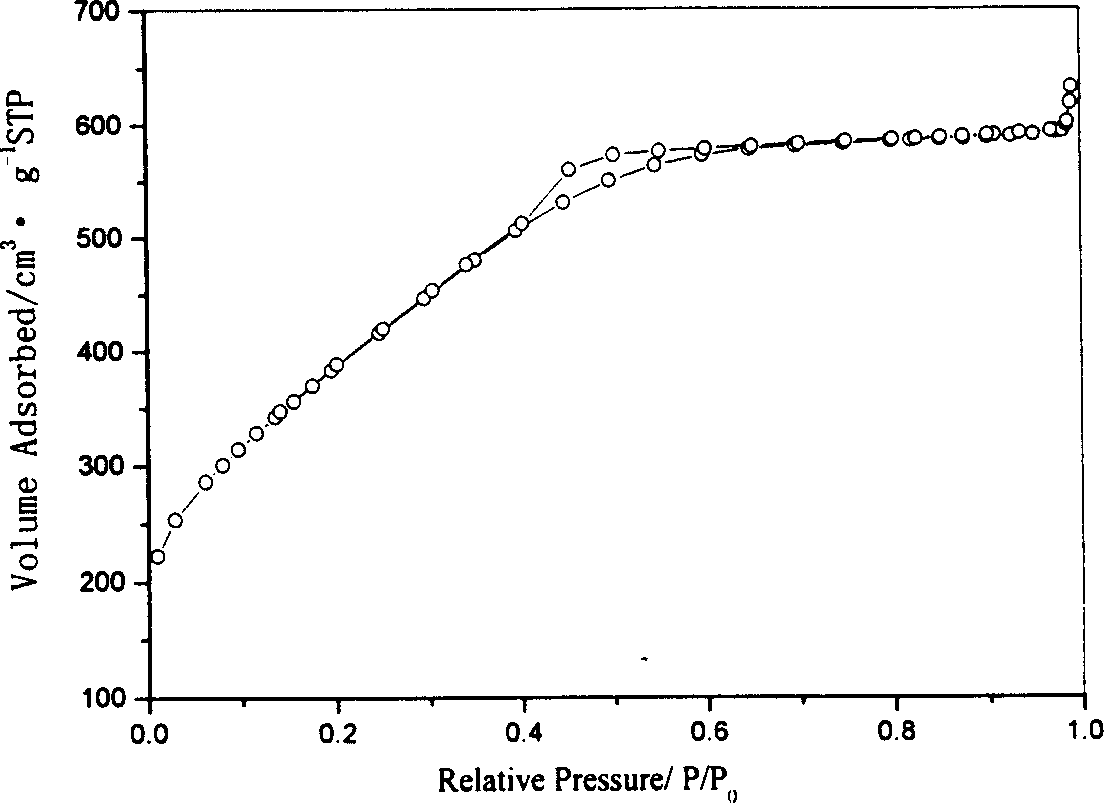

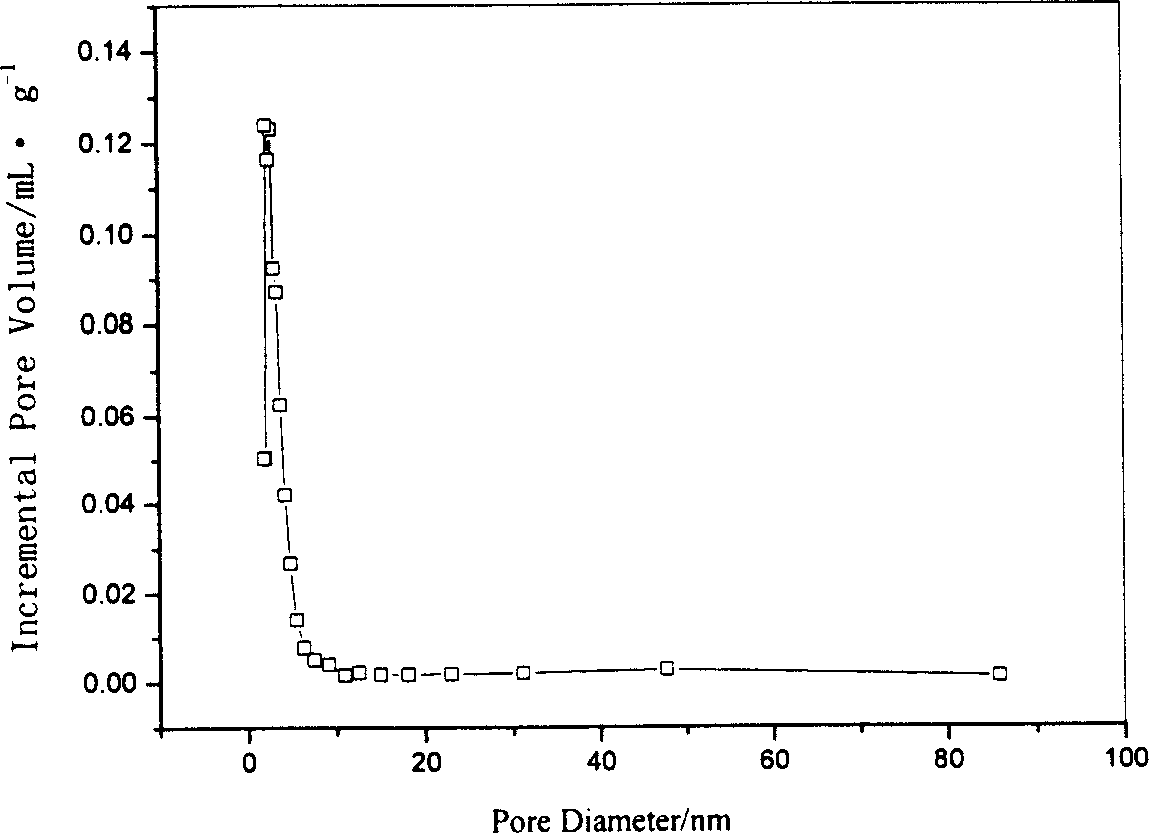

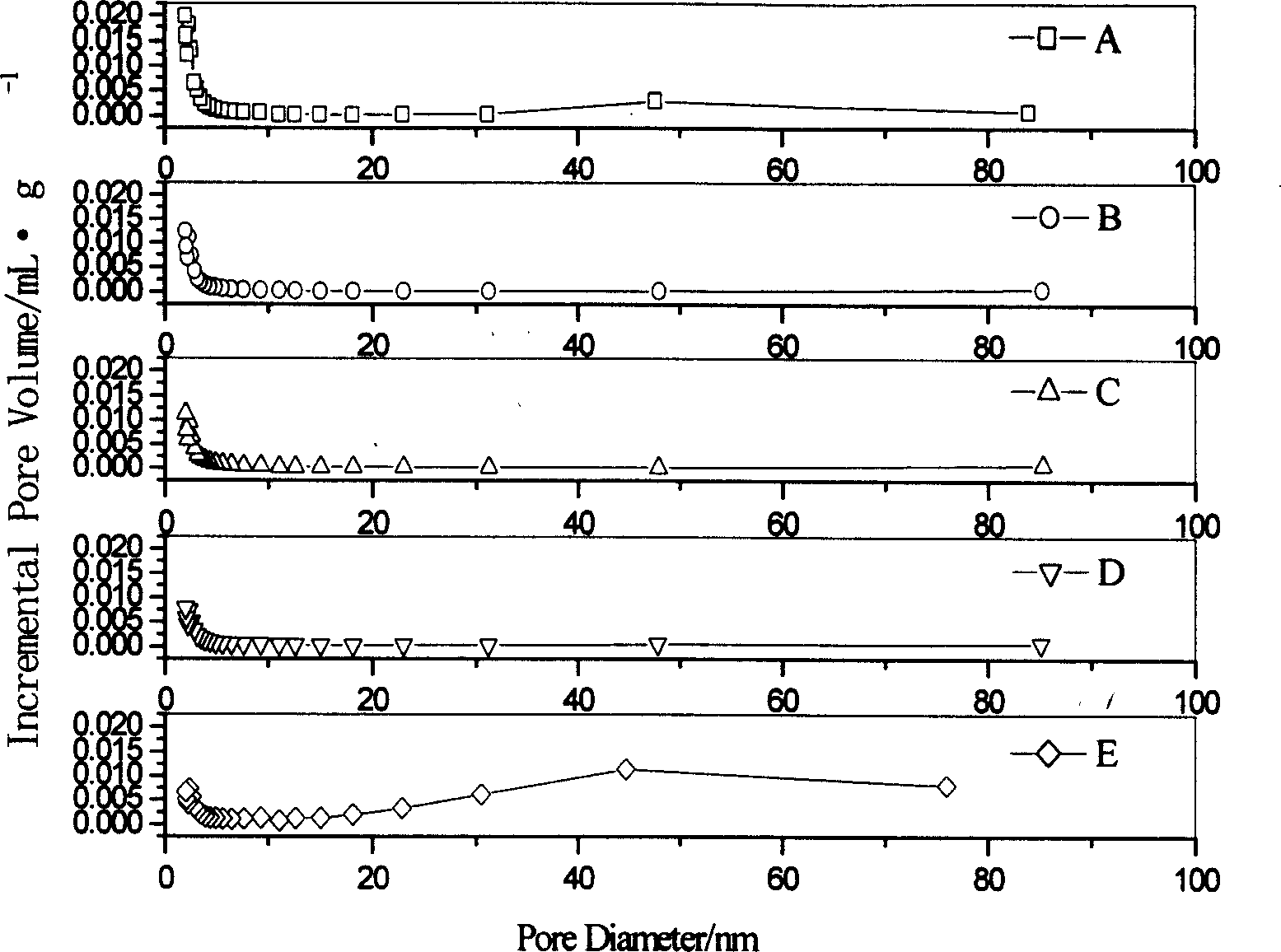

Image

Examples

Embodiment 1

[0018] Get polyacrylonitrile hollow fiber raw material 1.5g and put into concentration at room temperature and be 4% weight (wt) (NH 4 ) 2 HPO 4 Soak in the aqueous solution for 30 minutes, let it dry naturally in the air, put it in an oven, heat it in the air at 230°C for 2 hours, and the pre-oxidation is over; then put the pre-oxidized fiber into the quartz tube in the tube furnace , heated to 900°C under the protection of nitrogen, heated at 900°C for 70 minutes, and the carbonization was completed; then the furnace temperature was naturally lowered to 800°C, and CO 2 gas, heated at 800°C for 40 minutes, the activation is over, and the CO is turned off 2 Gas, use a vacuum pump to remove CO from the quartz tube 2 Gas, and then nitrogen gas, when the nitrogen pressure in the quartz tube is 1 atmosphere, seal the two ends of the quartz tube, turn off the nitrogen, until the temperature in the quartz tube drops to room temperature, take out the hollow fiber, which is the fin...

Embodiment 2

[0020] The above-mentioned activated carbon fiber is effective for small molecular substances (creatinine) and medium molecular substances (VB 12 ) adsorption rate is shown in the following table: at 37 ° C, creatinine and VB 12 Static adsorption in aqueous solution for 24 hours.

[0021] name

Embodiment 3

[0023] BET specific surface area (m 2 g -1 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com