Core-shell polymer having hydrophilic shell for improved shell coverage and anti-blocking property

An elastic polymer, polymer technology, used in the field of impact modifiers, can solve problems such as incompleteness and uneven thickness of the polymer shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1 (comparative example)

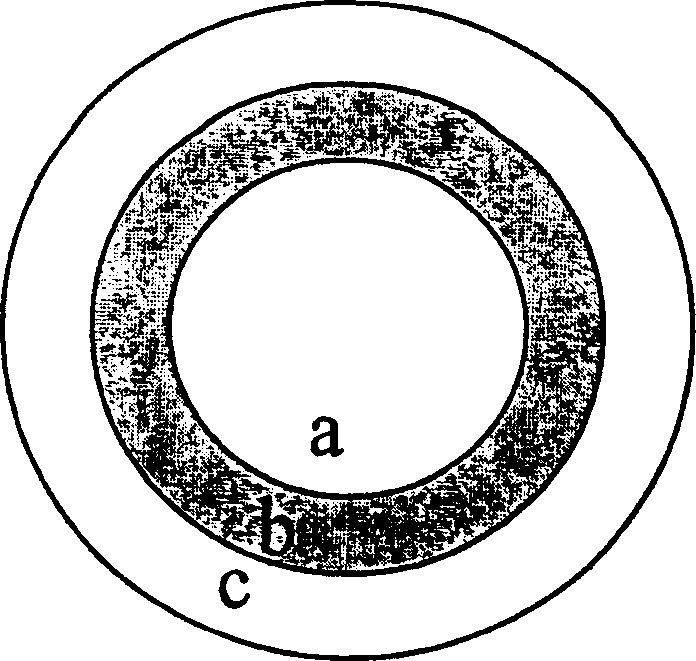

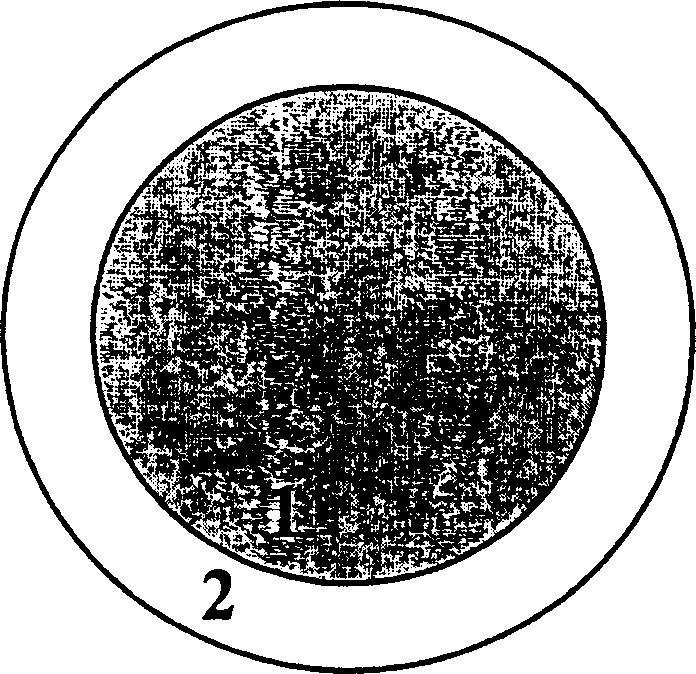

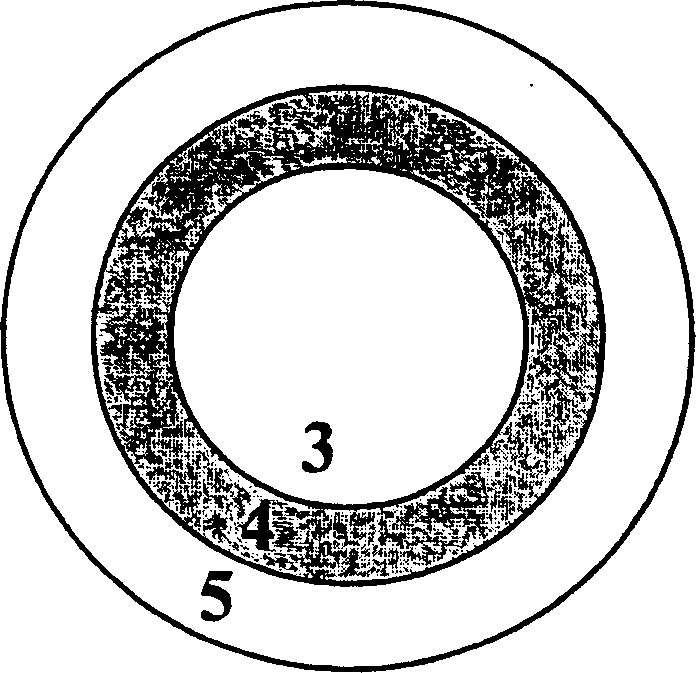

[0086] The following procedure was used to synthesize multistage impact modifiers having a hard core, an elastic or soft layer and a hard shell (see image 3 ).

[0087] The ratio of the tertiary polymer is 35 / 45 / 20 and its refractive index is between 1.460-1.500.

[0088] The composition of the tertiary polymer is

[0089] Level 1: 74.8 / 25 / 0.2MMA / EA / ALMA

[0090] Level 2: 83.5 / 15.5 / 1.0BA / Sty / ALMA

[0091] The third level: 95 / 5MMA / EA

[0092] where MMA = methyl methacrylate

[0093] EA = ethyl acrylate

[0094]BA = butyl acrylate

[0095] Sty = styrene

[0096] ALMA = allyl methacrylate

[0097] The monomer material accounting for 14% of the total material in the first stage is emulsified in water, using potassium dodecylbenzenesulfonate as emulsifier, controlling pH with potassium carbonate, and polymerizing it at high temperature with potassium persulfate. The remainder of the first stage is then added to the preformed po...

Embodiment 2

[0099] Prepare this polymkeric substance with the method similar to embodiment 1, difference is that the composition ratio of polymer of various stages is different:

[0100] Tertiary polymer ratio 35 / 45 / 20

[0101] The composition of the tertiary polymer is

[0102] Level 1: 74.8 / 25 / 0.2MMA / EA / ALMA

[0103] Level 2: 83.5 / 15.5 / 1.0BA / Sty / ALMA

[0104] Level 3: (95-X) / 5 / X MMA / EA / HEMA

[0105] where X=5

[0106] HEMA = 2-hydroxyethyl methacrylate

Embodiment 3

[0108] Except X=10, with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com