Agar-digesting enzyme and utilization thereof

A technology for decomposing enzymes and agar, applied in the direction of application, hydrolytic enzymes, enzymes, etc., can solve problems such as difficult application in industry, high price, and inability to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0212] Screening of agar decomposing bacteria:

[0213] The seabed soil samples stored in the Marine Science and Technology Center were appropriately diluted with Marine broth 2216 culture solution (manufactured by Difco), inoculated on Marine agar plate medium, and cultured at various temperatures from 15°C to 55°C for 16 to 48 hours. The bacteria that decomposed the agar around the colony and formed depressions on the applied plate medium were inoculated on another Marine agar plate medium, and cultured under the temperature conditions suitable for the bacteria. Then, streak culture was repeatedly performed on the same medium to isolate agar-decomposing bacteria.

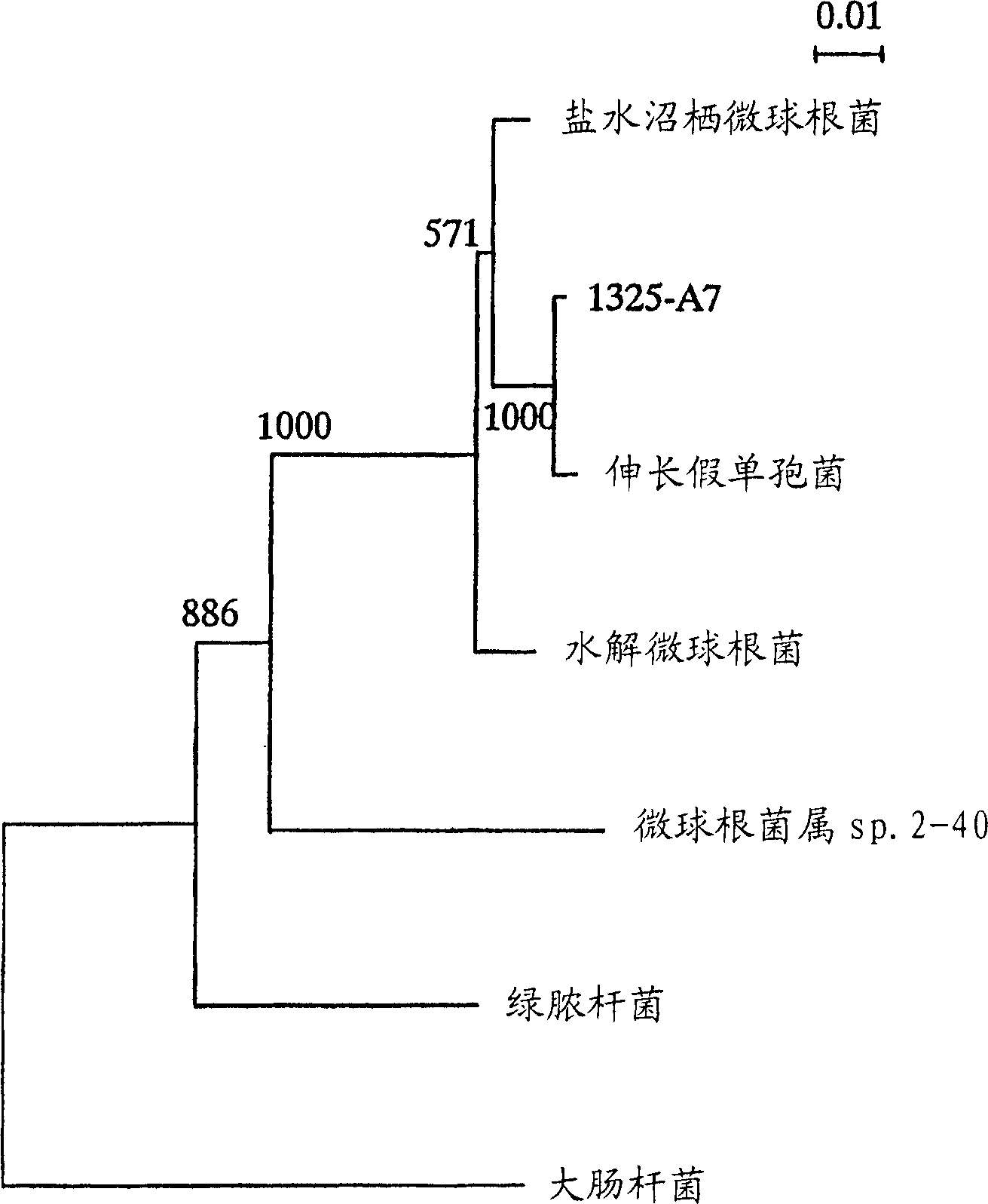

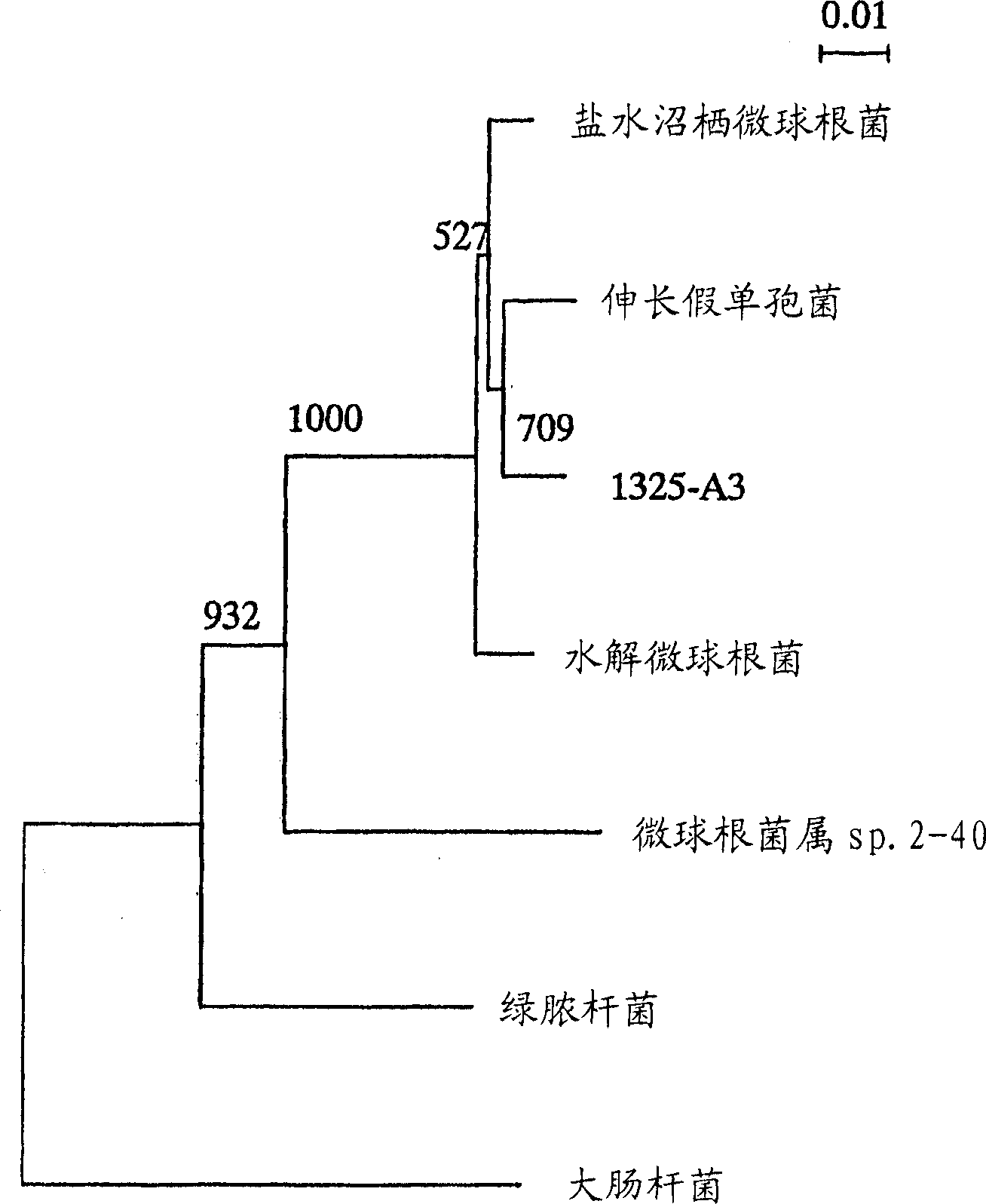

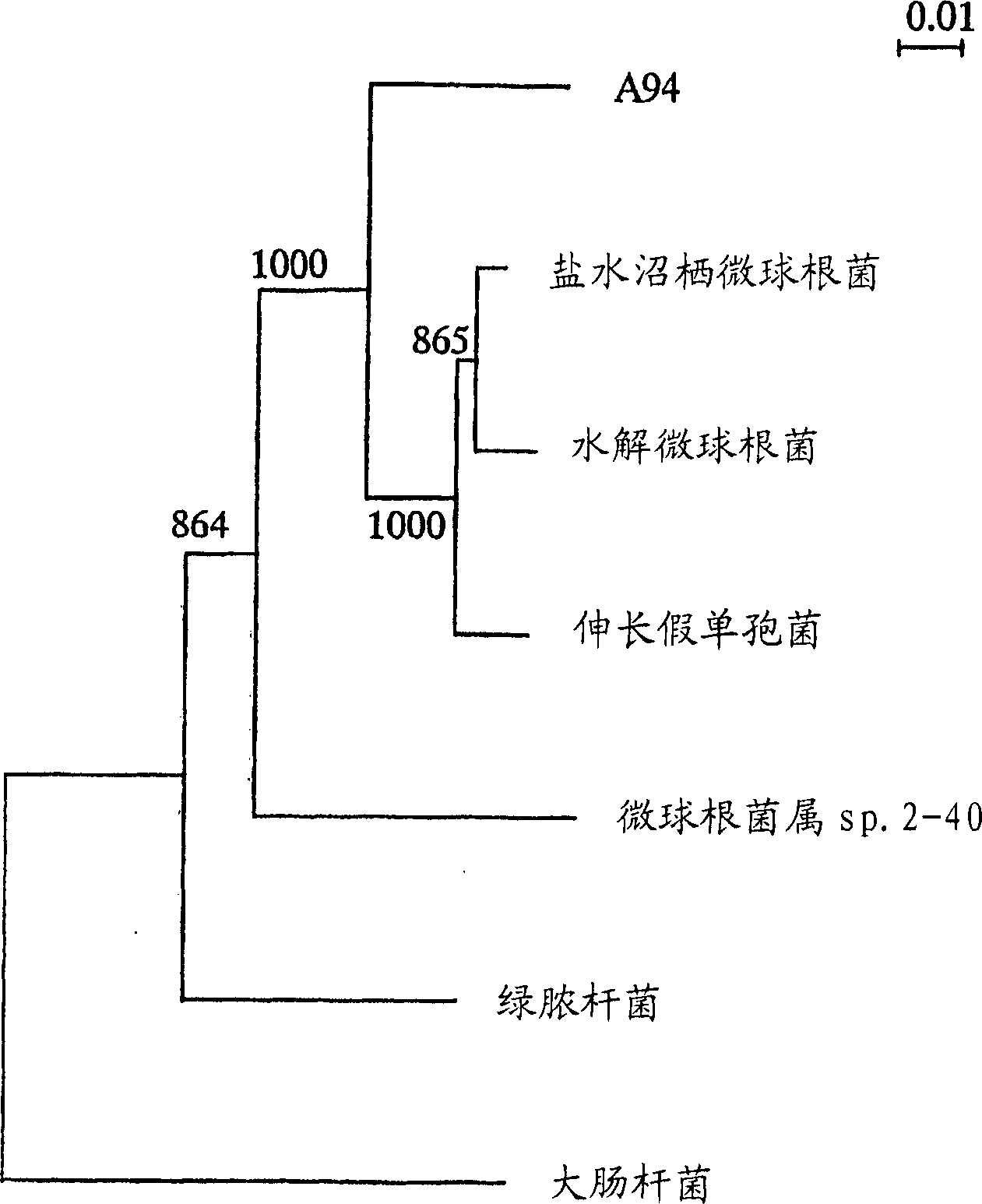

[0214] The 1325-A7 strain, the 1325-A3 strain, and the A94 strain were obtained from the agar-degrading bacteria screened as above, and these strains are microorganisms capable of producing agar-degrading enzymes with higher agar-degrading enzyme activities than conventionally known. Using the CLUSTAL×Multiple Se...

Embodiment 2

[0216] (1) Analysis of agarase gene (1)

[0217] The chromosomal DNA of the Microglobosa sp.1325-A7 strain (hereinafter abbreviated as "1325-A7 strain") was digested with HindIII and EcoRI to obtain a DNA fragment. This DNA fragment was purified using a High Purity PCR Product Purification Kit (manufactured by Roche) to obtain a purified DNA fragment. This purified DNA fragment was ligated with the plasmid vector pUC18 (manufactured by TaKaRa) previously digested with HindIII and EcoRI using DNA Ligation Kit ver.2.0 (manufactured by TaKaRa). E. coli HB101 (F'supE44 hsdS20 recA13 ara-14 proA2lacY1 galK2 rpsL20 xyl-5mtl-1 leuB6 thi-1) was transformed with this ligation mixture to prepare a transformant.

[0218] The transformant prepared as above was inoculated on an agar medium, and the colonies forming depressions on the agar medium were selected as clones having agar-decomposing activity. Mark the selected clones with agar decomposing activity on LB agar medium (1% bactocul...

Embodiment 3

[0259] (1) Analysis of agarase gene (2)

[0260] The chromosomal DNA of the Microglobulina sp.1325-A3 strain (hereinafter abbreviated as "1325-A3 strain") was digested with HindIII to obtain a DNA fragment. This DNA fragment was purified using a High Purity PCR Product Purification Kit (manufactured by Roche) to obtain a purified DNA fragment. This purified DNA fragment was ligated with plasmid vector pUC18 (manufactured by TaKaRa) previously digested with HindIII and treated with shrimp alkaline phosphatase (manufactured by Roche) using DNA Ligation Kit ver.2.0 (manufactured by TaKaRa). E.coliHB101 (F'supE44 hsdS20 recA13 ara-14proA2 lacY1 galK2 rpsL20 xyl-5mtl-1 leuB6 thi-1) was transformed with this ligation mixture to prepare a transformant.

[0261] The transformant prepared as above was inoculated on an agar medium, and the colonies forming depressions on the agar medium were selected as clones having agar-decomposing activity. Place the selected clones with agar decom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com