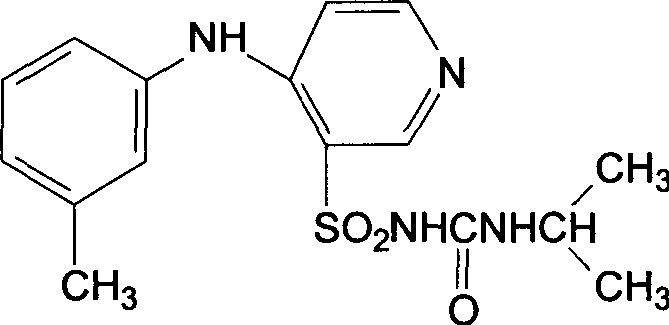

Disperese torasemide tablet and its prepn and application

A technology of torasemide and dispersible tablets, which is applied in the field of medicine and can solve problems such as the influence of drug absorption, slow disintegration speed, and inconvenience in taking medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Prescription composition:

[0028] Torsemide 20g

[0029] Microcrystalline Cellulose 50g

[0030] Carboxymethyl Starch Sodium 6g

[0031] Hypromellose 15g

[0032] Stevia 6g

[0034] 70% ethanol appropriate amount

[0035] Makes 1000 pieces

[0036] (2) Preparation process

[0037] 1. Grind the torasemide and auxiliary materials through a 100-mesh sieve, and set aside;

[0038] 2. Accurately weigh the raw and auxiliary materials according to the prescription quantity, first mix microcrystalline cellulose, hydroxypropyl cellulose, and stevioside auxiliary materials evenly, and then mix with the main drug, add 70% ethanol to make a soft material, and granulate with a 20-mesh sieve , dried at 55°C, sieved with a 60-mesh sieve, added sodium starch glycolate and talcum powder and mixed evenly;

[0039] 3. Measure the particle content and calculate the tablet weight;

[0040] 4. Tablet, ready to use.

Embodiment 2

[0042] (1) Prescription composition:

[0043] Torsemide 10g

[0044] Microcrystalline Cellulose 60g

[0045] Carboxymethyl Starch Sodium 6g

[0046] Hypromellose 15g

[0047] Stevia 6g

[0049] 70% ethanol appropriate amount

[0050] Makes 1000 pieces

[0051] (2) Preparation process

[0052] 1. Grind the torasemide and auxiliary materials through a 100-mesh sieve, and set aside;

[0053] 2. Accurately weigh the raw and auxiliary materials according to the prescription quantity, first mix microcrystalline cellulose, hydroxypropyl cellulose, and stevioside auxiliary materials evenly, and then mix with the main drug, add 70% ethanol to make a soft material, and granulate with a 20-mesh sieve , dried at 55°C, sieved with a 60-mesh sieve, added sodium starch glycolate and talcum powder and mixed evenly;

[0054] 3. Measure the particle content and calculate the tablet weight;

[0055] 4. Tablet, ready to use.

Embodiment 3

[0057] (1) Prescription composition:

[0058] Torsemide 5g

[0059] Microcrystalline Cellulose 65g

[0060] Carboxymethyl Starch Sodium 6g

[0061] Hypromellose 15g

[0062] Stevia 6g

[0063] Talc powder 3g

[0064] 70% ethanol appropriate amount

[0065] Makes 1000 pieces

[0066] (2) Preparation process

[0067] 1. Grind the torasemide and auxiliary materials through a 100-mesh sieve, and set aside;

[0068] 2. Accurately weigh the raw and auxiliary materials according to the prescription quantity, first mix microcrystalline cellulose, hydroxypropyl cellulose, and stevioside auxiliary materials evenly, and then mix with the main drug, add 70% ethanol to make a soft material, and granulate with a 20-mesh sieve , dried at 55°C, sieved with a 60-mesh sieve, added sodium starch glycolate and talcum powder and mixed evenly;

[0069] 3. Measure the particle content and calculate the tablet weight;

[0070] 4. Tablet, ready to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com