Prepn process of mofe-til mycophenolate

A technology of mycophenolate morphinate and mycophenolic acid, which is applied in the field of preparation of mycophenolate mofetil, can solve problems such as multi-step reaction, product lavender cannot be removed, and instability, so as to shorten the reaction time and solve the problem of Product color problem, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

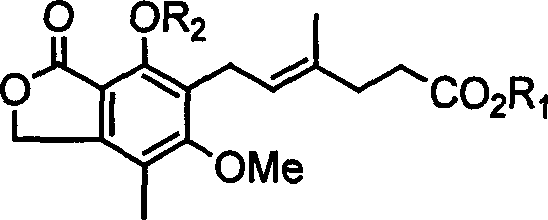

Image

Examples

Embodiment 1

[0021] Using formic acid as a catalyst and dropping into a decolorizing agent vitamin C to remove purple mycophenolate mofetil preparation method comprises the following steps in turn:

[0022] (1) Put 20g of mycophenolic acid and 60mL of a mixed solvent of toluene and xylene (3:1) into a reactor with a reflux water separation device, stir until dissolved, and then put in 11.5g of morpholinoethanol;

[0023] (2) drop into 1g catalyst low-grade fat and acid-formic acid;

[0024] (3) Raise the temperature to 130°C, stir, reflux and divide the water, keep the temperature for 10 hours, then cool down and directly esterify, track the purity (HPLC), and the reaction conversion rate reaches 85% in about 8 hours;

[0025] (4) 1.5 g of activated carbon was added to decolorize at a temperature of 80° C. for 0.5 hours, suction filtered, and the mother liquor was evaporated to dryness under reduced pressure at a temperature below 70° C.;

[0026] (5) Dissolve with 150ml of ethyl acetate,...

Embodiment 2

[0029] Using acetic acid as a catalyst and dropping into the decolorizer vitamin C to remove the purple mycophenolate morphinate preparation method comprises the following steps in turn:

[0030] (1) with the step (1) of embodiment 1;

[0031] (2) drop into 1g catalyst lower fatty acid-acetic acid,

[0032] (3) Raise the temperature to 129°C, stir, reflux and divide the water, keep the temperature for 24 hours, then cool down and directly esterify;

[0033] (4) with the step (4) of embodiment 1;

[0034] (5) basically with the step (5) of embodiment 1, vitamin C input amount is 0.07g;

[0035] (6) Basically the same as the step (1) of the embodiment, 22.00 g of mycophenolate mofetil was obtained, the purity (HPLC) was 99.7%, and the yield was 83.0%.

Embodiment 3

[0037] Using propionic acid as a catalyst and dropping into the decolorizing agent vitamin C to remove purple mycophenolate mofetil preparation method comprises the following steps in turn:

[0038] (1) substantially with the step (1) of embodiment 1, the input amount of morpholino ethanol is 11.5g;

[0039] (2) drop into 1g catalyst lower fatty acid-propionic acid,

[0040] (3) Heating up to 127°C, stirring, reflux and water separation, keeping the temperature for 24 hours, and then cooling down for direct esterification;

[0041] (4) with the step (4) of embodiment 1;

[0042] (5) basically with the step (5) of embodiment 1, vitamin C input amount is 0.16g;

[0043] (6) Basically the same as the step (1) of Example 1, 21.20 g of mycophenolate mofetil was obtained, the purity (HPLC) was 99.6%, and the yield was 80.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com