Portable electronic device case and producing method thereof

A technology for electronic devices and manufacturing methods, which is applied in the fields of electrical equipment shells/cabinets/drawers, chemical instruments and methods, and electrical components, and can solve the problems of monotonous colors, poor hardness and wear resistance of magnesium alloy shells, and easy to damage the surface of magnesium alloy shells. Wear and other problems, to achieve the effect of improving properties, hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The portable electronic device shell of the present invention is suitable for portable electronic devices such as mobile phones, PDAs, and digital cameras.

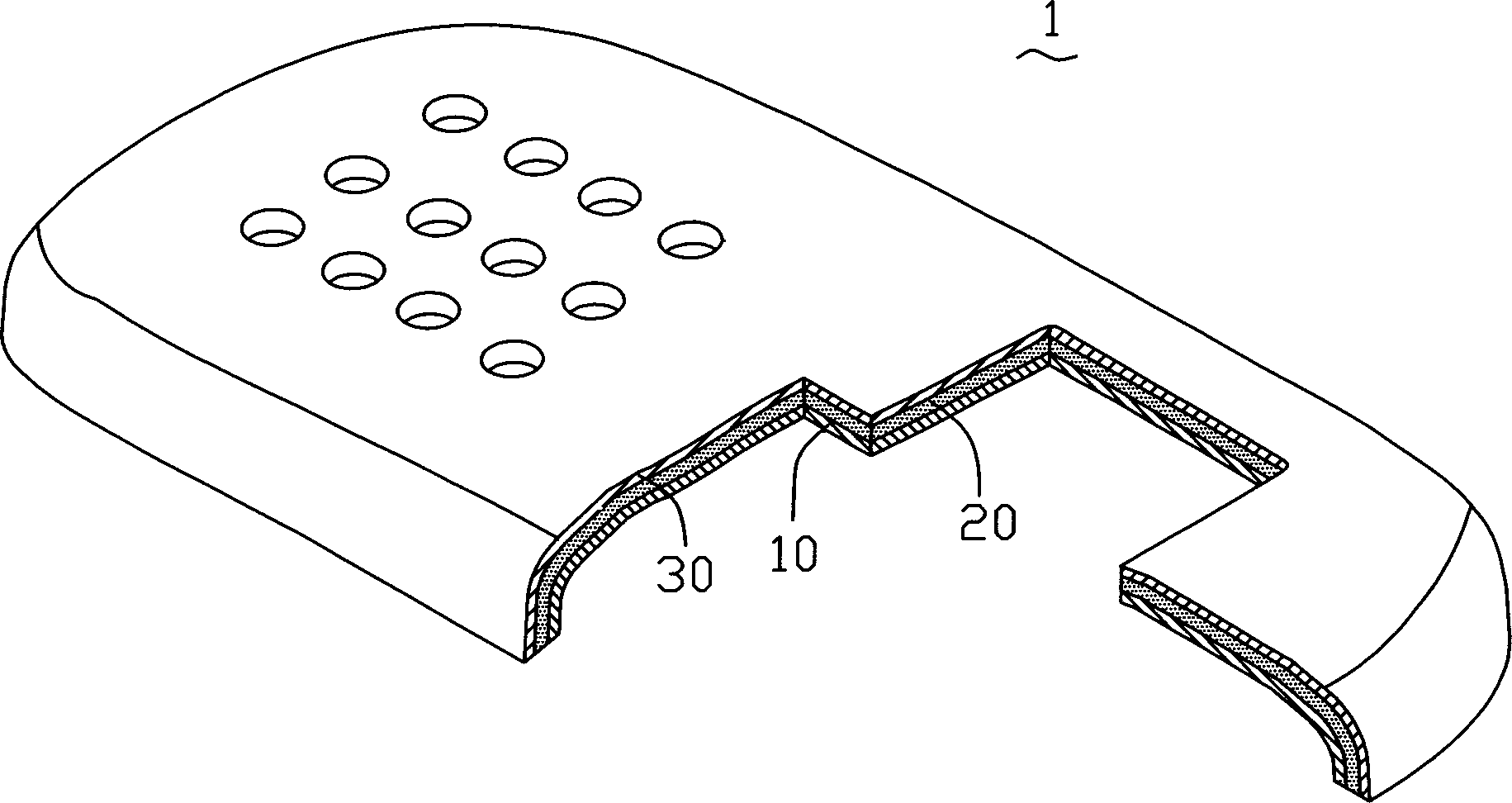

[0016] refer to figure 1 As shown, the portable electronic device casing 1 of the present invention includes a magnesium alloy substrate 10 and an aluminum alloy coating layer 20, wherein the aluminum alloy coating layer 20 covers the surface of the magnesium alloy substrate 10, and the surface of the aluminum alloy coating layer 20 is anodized The treatment forms an anodized layer 30 .

[0017] The manufacturing method of the portable electronic device casing 1 comprises the following steps:

[0018] Provide a magnesium alloy substrate 10, cleaned after polishing;

[0019] Put the magnesium alloy substrate 10 into a vacuum coating chamber, and evacuate the vacuum coating chamber;

[0020] Using aluminum metal as a sputtering target, sputtering an aluminum alloy coating layer 20 on the surface of the magnesium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com