Plane display with VMOS cathode structure and manufacturing technology

A cathode structure and display technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of affecting the voltage, poor adhesion, and carbon nanotubes falling off, etc., to reduce Production cost, the effect that is conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

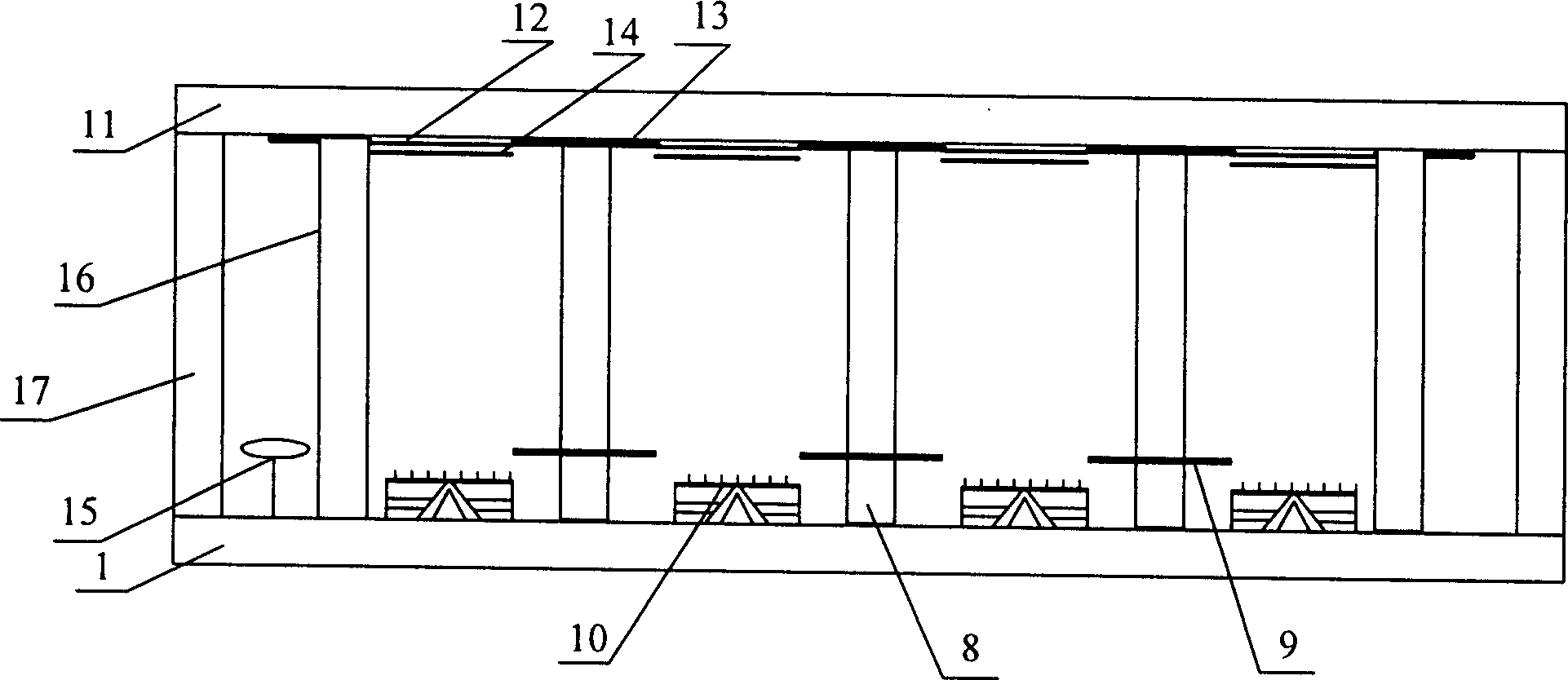

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

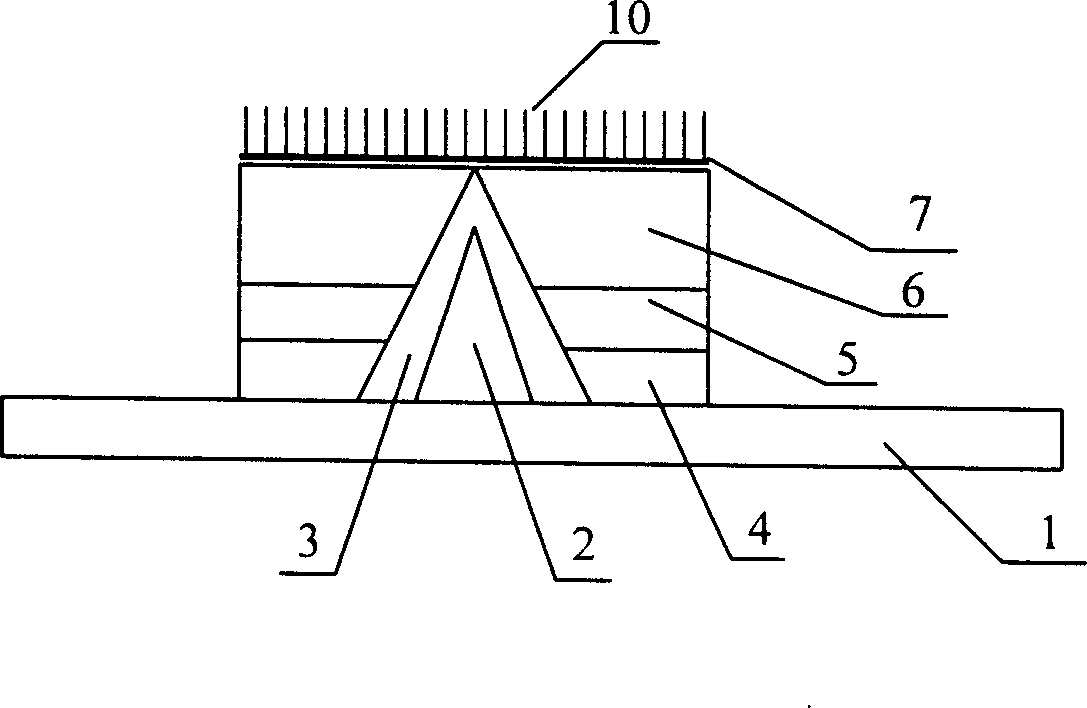

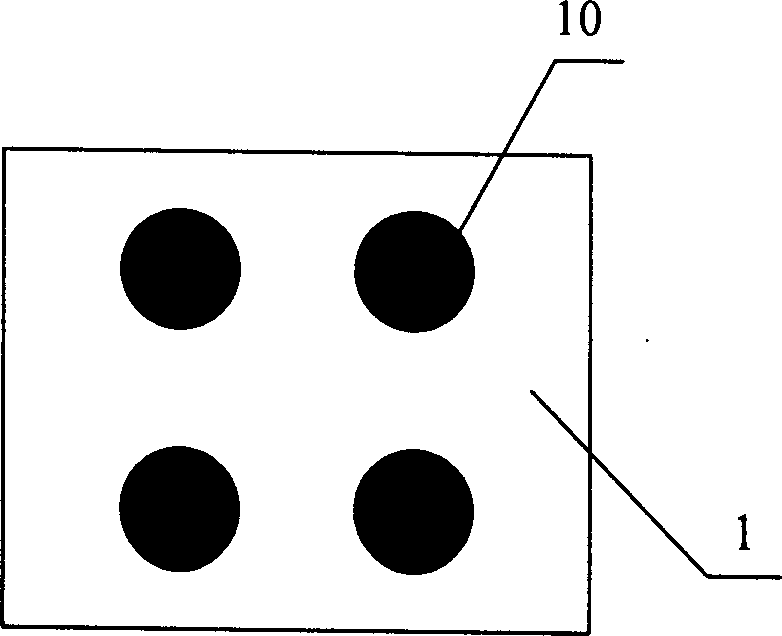

[0056] The VMOS cathode structure in the present invention includes cathode glass panel 1, metal layer 2, insulating layer 3, n-type heavily doped silicon layer [4], p-type doped silicon layer [5], n-type doped silicon layer [6] ], cathode electrode layer [7], and use the following process to make:

[0057] 1. Fabrication of cathode glass panel [1]

[0058] Cut the whole flat soda-lime glass to make the cathode glass panel[1];

[0059] 2. Fabrication of the metal layer [2]

[0060] Prepare a chromium layer on the cathode glass panel; combine the conventional photolithography process to etch the chromium layer to form a metal layer [2]; the middle part of the etched chromium layer is required to form an inverted "V" shape structure, with the tip pointing away from the cathode glass panel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com