Method of producing laser-processed product and adhesive sheet, for laser processing used therefor

A technology of laser processing and manufacturing method, which is applied in manufacturing tools, film/sheet adhesives, semiconductor/solid-state device manufacturing, etc. The effect of precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

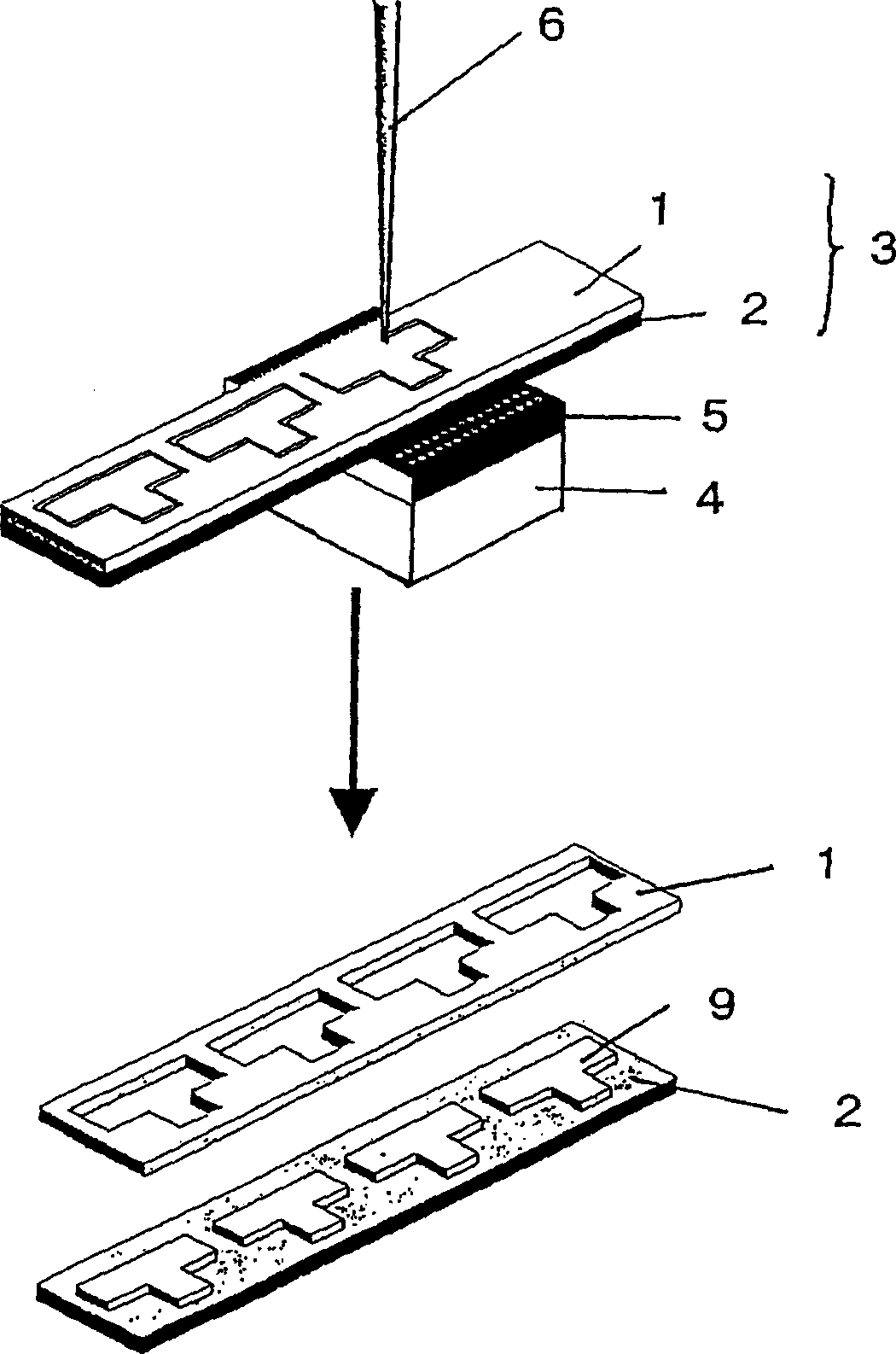

no. 1 Embodiment approach

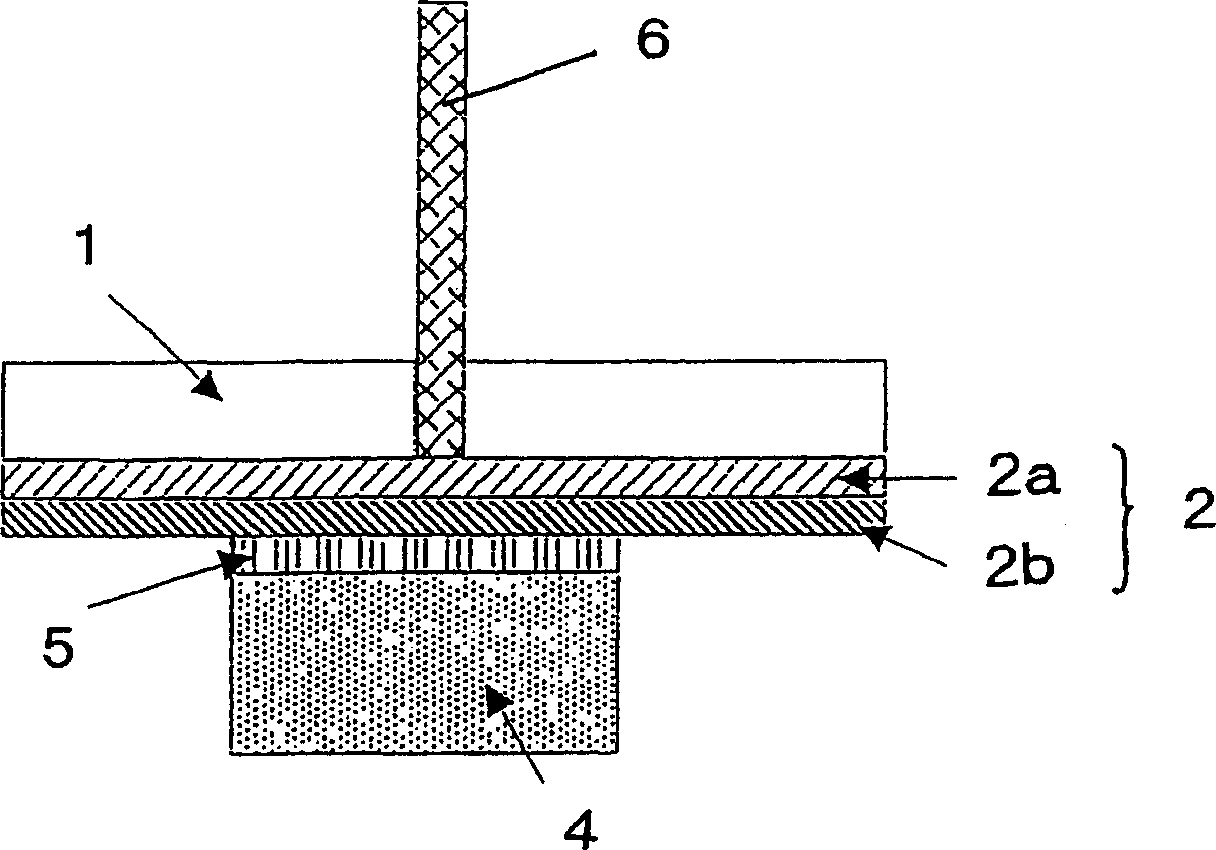

[0107] [adhesive sheet]

[0108] First, the PSA sheet used in the first embodiment of the present invention will be described. The pressure-sensitive adhesive sheet in this embodiment is used when processing a workpiece by ablation using laser light having a wavelength in the ultraviolet region or laser light capable of absorbing light in the ultraviolet region through a multiphoton absorption process. Its structure is that at least an adhesive layer is provided on a substrate (details of the substrate and the adhesive layer will be described later). As the PSA sheet used in this embodiment, there are eight types of PSA sheets A to H described below in more detail.

[0109] (adhesive sheet A)

[0110] The pressure-sensitive adhesive sheet A has physical properties such that the ratio of the light absorption coefficient obtained in the following formula (1) is less than 1 when irradiated with laser light whose intensity causes ablation of the workpiece The irradiation intens...

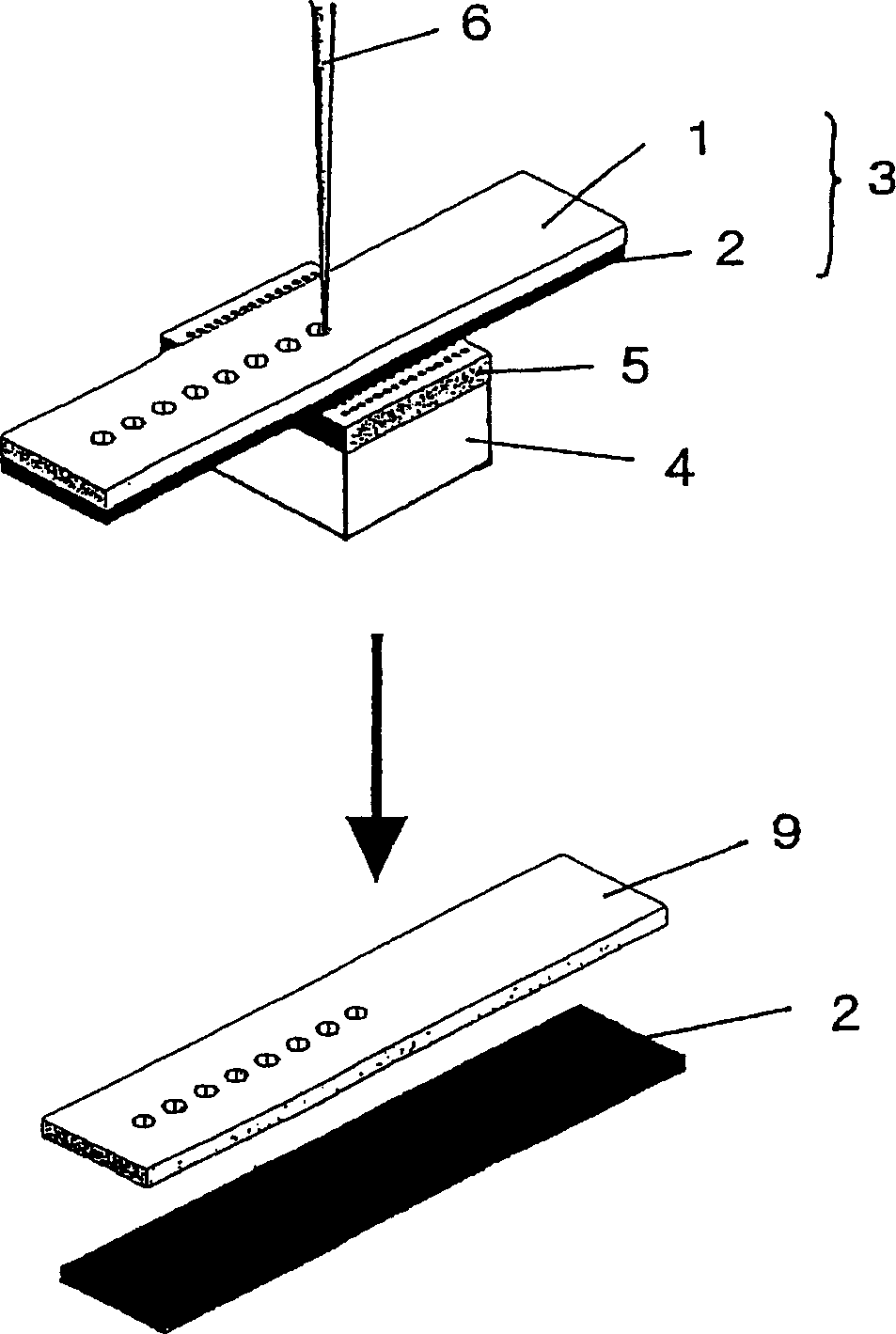

no. 2 Embodiment approach

[0195] The second embodiment relates to a method of performing laser processing on a workpiece made of a metal-based material in particular.

[0196] [adhesive sheet]

[0197] As the PSA sheet used in this embodiment, there are six types of PSA sheets A' to F' described below. Note that detailed descriptions of components having the same functions as those of the various pressure-sensitive adhesive sheets of the first embodiment described above are omitted.

[0198] (adhesive sheet A')

[0199] Compared with the above-mentioned adhesive sheet A, the adhesive sheet A' has an absorption coefficient of less than 20 cm at a relative wavelength of 355 nm laser light. -1 This is different.

[0200] In the case where the workpiece is made of a metal-based material, when the PSA sheet A' in this embodiment shows a light of less than 20 cm at 355 nm light, -1 When the light absorption coefficient of , it is shown that the adhesive sheet A' is more difficult to process than the proc...

Embodiment 1

[0229] The following examples and the like correspond to the above-mentioned adhesive sheets A and A'.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com