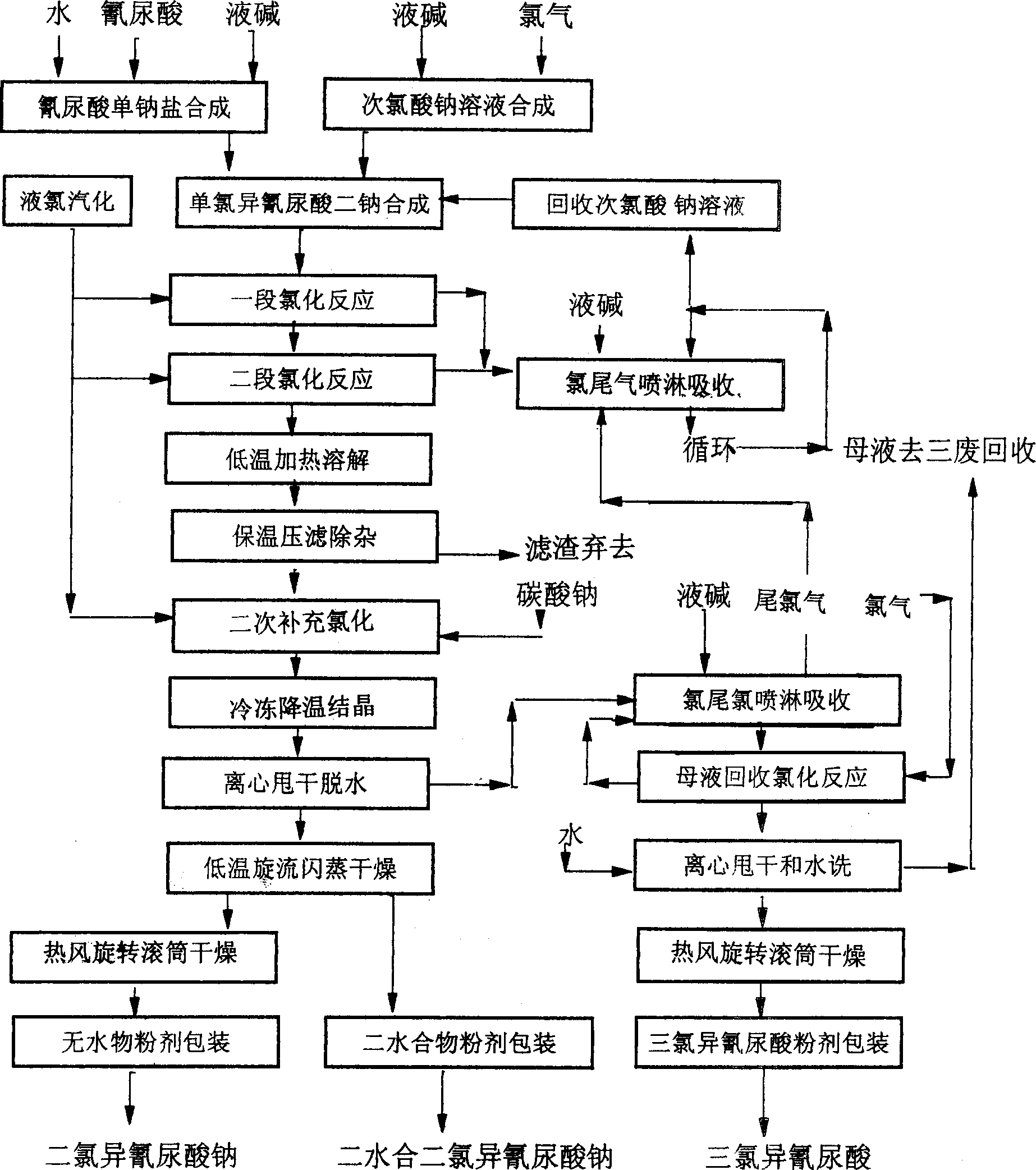

One step method of continuously synthesizing sodium dichloro ise cyanurate linking producing trichloro isocyanurate using sodium hypochlorite

A technology of sodium dichloroisocyanurate and trichloroisocyanuric acid, which is applied in the direction of organic chemistry, can solve problems such as complicated operation, poor solubility, and poor production environment, so as to save manpower and power, improve production efficiency, The effect of short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Production method with an annual output of 1,700 tons of sodium dichloroisocyanurate and 300 tons of sodium trichloroisocyanurate in parallel:

[0035] (1) Production of monosodium dicyanuric acid:

[0036] 1. Preparation of Chloruric Acid Monosodium Salt Suspension:

[0037]In a 2000-liter glass-lined reactor equipped with a stirring mechanism, a thermometer, an industrial acidity meter, a feed port, and a jacket for heat exchange, add 1200 kg of warm water preheated to 32-34 ° C, and add powder with a content of ≥ 98.5% cyanuric acid 340kg, stir to make it into a uniform slurry suspension. Slowly add 20% caustic soda solution under stirring and keep the reaction temperature not lower than 35°C until the pH value of the reaction suspension is 8.5, stop adding caustic soda, stir and react for 30 minutes, if the pH value remains unchanged at 8.5, the reaction is complete (The amount of adding 20% liquid caustic soda is 518.8~521.5kg). After the reaction, 2,058.8 to ...

Embodiment 2

[0073] The annual output of sodium dichloroisocyanurate is 5,000 tons, and the joint production of sodium trichloroisocyanurate is 900 tons.

[0074] (1) Production of monosodium dicyanuric acid:

[0075] 1. Preparation of monosodium cyanuric acid suspension:

[0076]In the 5000-liter glass-lined reactor with the same device as in Example 1 (one) 1, add 3000 kg of warm water preheated to 32 to 34 ° C, and add 850 kg of fine powder content ≥ 98.5% cyanuric acid under stirring, press Embodiment 1 (one) The operating procedure and operating conditions of 1 add caustic soda and dissolve and neutralize to pH value 8.5 (adding 20% liquid caustic soda amount is 1295~1304kg), reaction completes and makes monosodium cyanurate monosodium suspension 5145~ 5154kg, the slurry liquid is pumped into a 5000-liter high-level glass reactor with stirring, thermometer and jacket heat exchange with a slurry pump and cooled to 20-25°C for later use.

[0077] 2. Preparation of monochloroisocyanu...

Embodiment 3

[0104] Tower-type single-stage chlorination full-continuous synthesis of sodium dichloroisocyanurate; the annual output of sodium dichloroisocyanurate is 5,000 tons, and the combined production of sodium trichloroisocyanurate is 900 tons.

[0105] (1) Production of monosodium dicyanuric acid:

[0106] 1. Preparation of monosodium cyanuric acid suspension:

[0107] According to "Example 2; (1) 1," the preparation of the monosodium cyanuric acid suspension was carried out with the same equipment, the same dosage, the same operating procedures and reaction conditions.

[0108] 2. Preparation of monochloroisocyanuric acid disodium salt solution

[0109] According to "Example 2; (1) 2," the same device, the same dosage, the same operating procedure and reaction conditions were used to prepare the monochloroisocyanuric acid disodium salt solution.

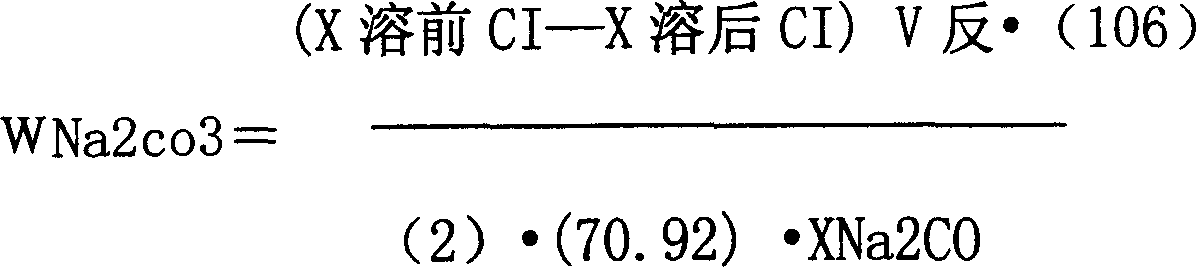

[0110] 3. Continuous chlorination reaction:

[0111] (1) Continuous chlorination reaction device: a glass-lined explosion-proof chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com