Method for making three-electrode flat-type display based on carbon nano-tube field emission array

The technology of a carbon nanotube and a manufacturing method is applied in the field of manufacturing a three-electrode flat display based on a carbon nanotube field emission array, and can solve the problems of high cost, low electron transmission efficiency, and difficulty in gate manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

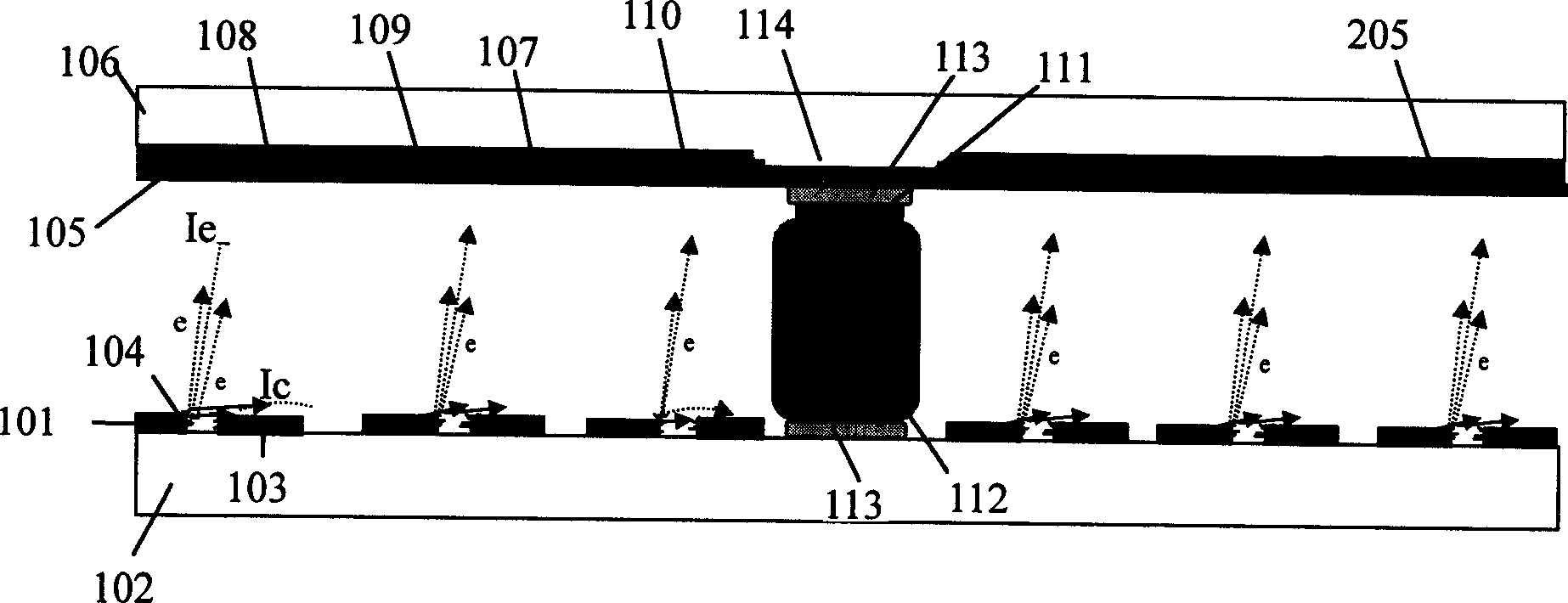

[0129] 1. Fabrication of glass grooves

[0130] The glass groove is directly formed on the rear substrate by physical or chemical etching. The process includes the formation of the template, uniform glue, exposure, sol, etching and other processes. It can also be printed by screen printing with glass glue Technology formation can also be formed by "sandblasting" with ion beams. The depth and width of glass grooves are generally around tens of microns to 100 microns, which are limited by process conditions and device spatial resolution.

[0131] 2. Preparation of carbon nanotube slurry

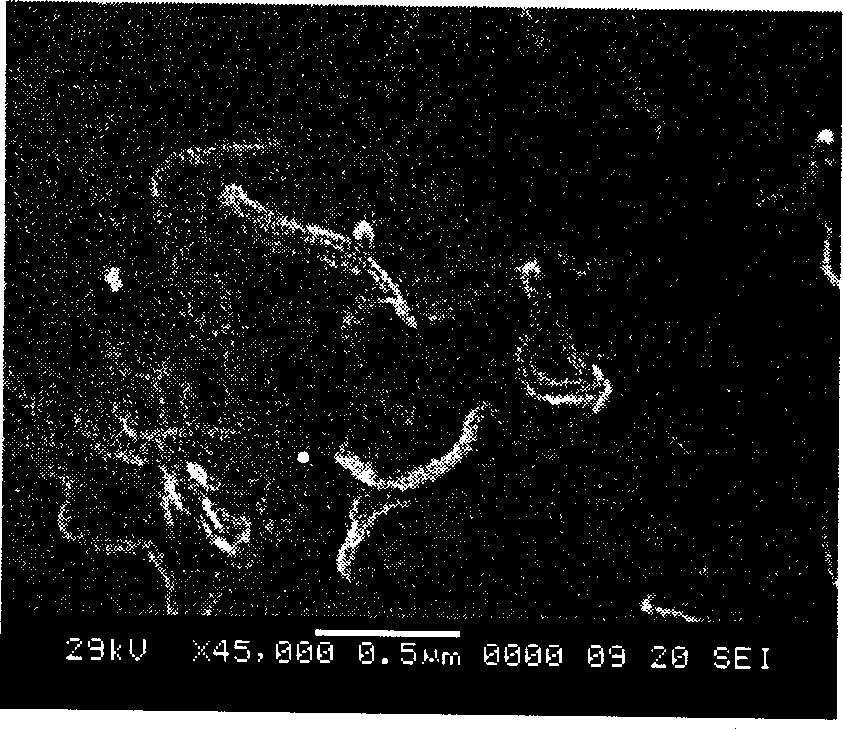

[0132] 1] Preparation and purification of carbon nanotubes. Regardless of whether it is single-walled or double-walled carbon nanotubes, the preparation and purification technologies are relatively mature. Among them, the preparation technologies include chemical vapor deposition, arc discharge, hot wire plasma, and laser ablation. It should be pointed out that What is more interesting is tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com