Toner for electrophotography and image forming apparatus

An electrophotography and toner technology, which is applied in the direction of electric recording process applying charge pattern, equipment and developer, etc., can solve the problem of printing plate contamination, toner fluidity or electrification. Deterioration of characteristics, failure to obtain image density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

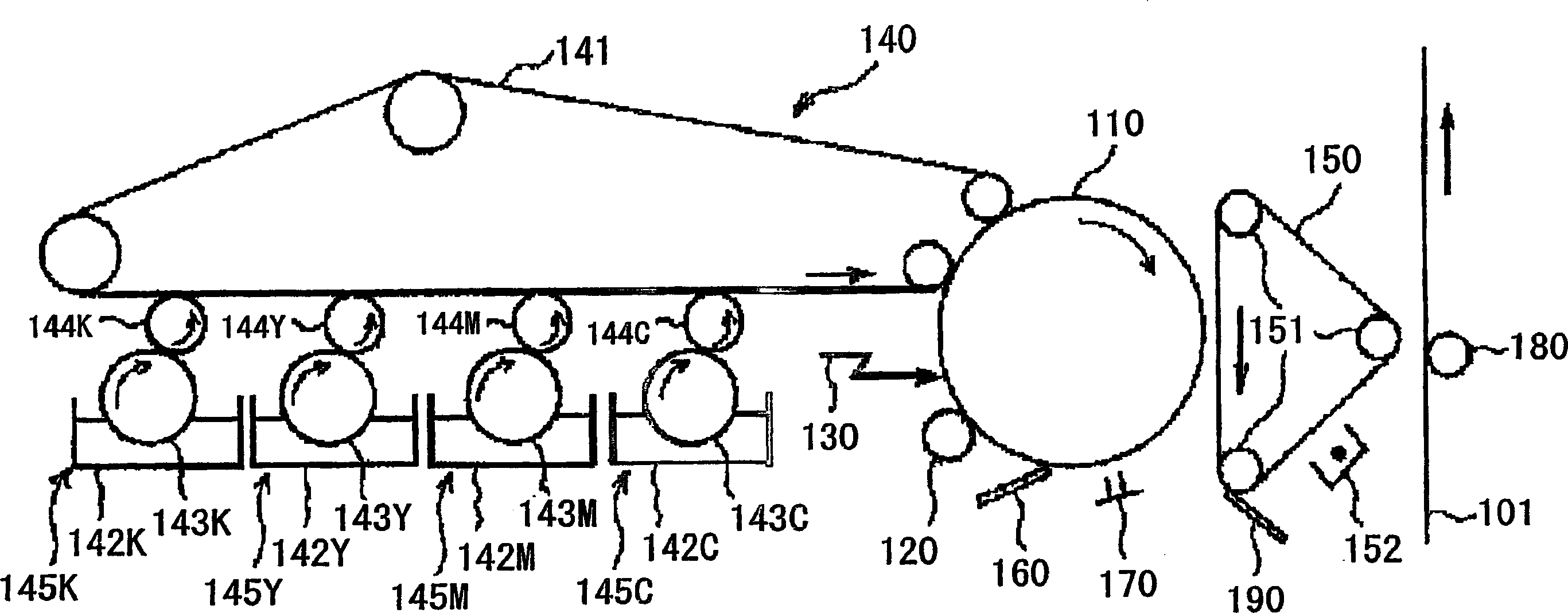

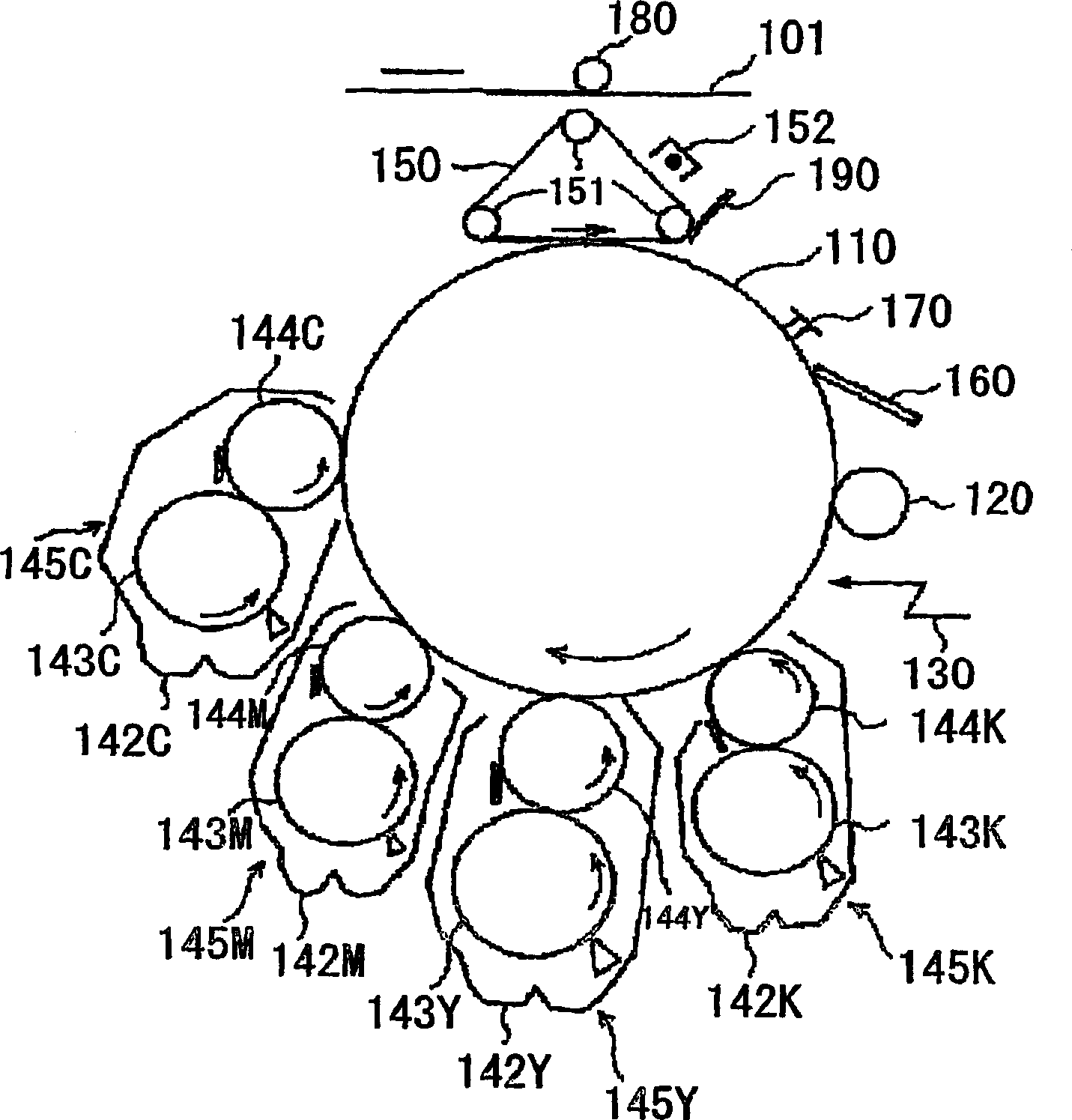

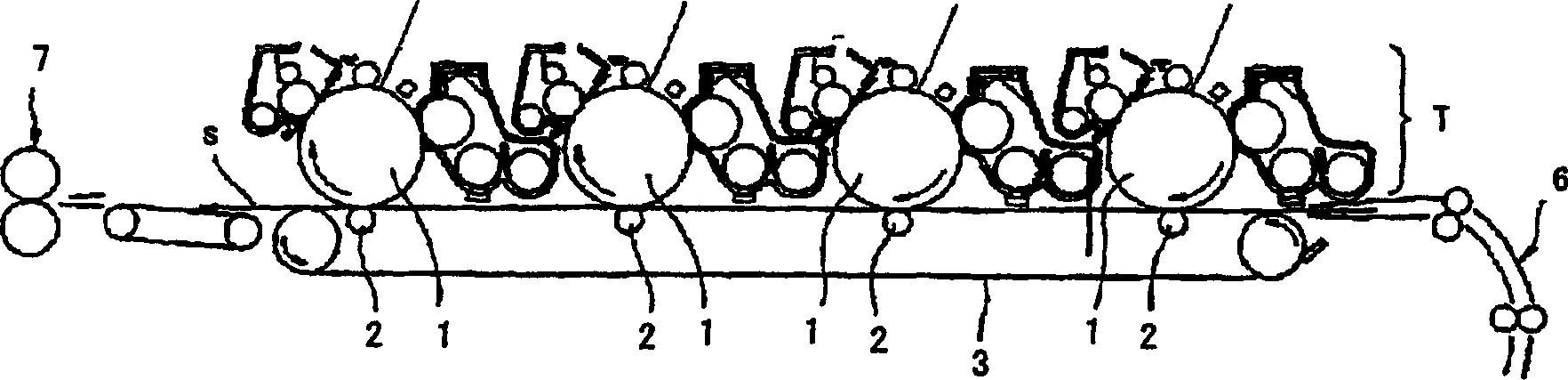

Image

Examples

Embodiment A

[0442] (Two-component developer evaluation)

[0443] When image evaluation is performed using a two-component system developer, as shown below, a ferrite carrier with an average particle diameter of 35 μm coated with a silicone resin with an average thickness of 0.5 μm is used in a form that is stirred by rotating the container. A twirling mixer uniformly mixed 7 parts by weight of toners of each color with respect to 100 parts by weight of the carrier and charged them to prepare a developer.

[0444] (manufacture of carrier)

[0445] ·Core

[0446] Mn ferrite fine particles (weight average particle diameter: 35 μm) 5000 parts by weight

[0447] ·Coating material

[0448] 450 parts by weight of toluene

[0449] Silicone resin SR2400 (manufactured by Toray Dou Corning Silicone Co., Ltd. (Silicon), 50% non-volatile content) 450 parts by weight

[0450] Aminosilane SH6020 (manufactured by Toray Dou Corning Silicone Co., Ltd.)

[0451] ...

Embodiment A-1

[0479] Hereinafter, for the specific production of the present invention "a toner composition comprising a binder resin containing a modified polyester resin capable of reacting with at least a compound having an active hydrogen group, a colorant, and a release agent Dissolving or dispersing in an organic solvent, dispersing the toner composition solution or dispersion in an aqueous medium containing resin particles, performing chain extension and / or crosslinking reactions, and removing the organic solvent from the obtained dispersion, Washing, drying, and the toner containing at least one kind or more than one kind of inorganic fine particles inside, (1) to (12) will be described in order.

manufacture example

[0481] Liquid SiCl as raw material for the core 4 Use a liquid raw material supply device to blow in argon as a carrier gas with a flow rate of 300SCCM (standard volume flow rate (CC) per minute), and SiCl with a flow rate of 250SCCM 4 Steam, hydrogen 20SLM (standard volume flow per minute (L)) and oxygen 20SLM are sent to the core burner for flame hydrolysis to fuse them to form SiO 2 particle. The microparticles are grown to a predetermined primary particle diameter, and the obtained microparticles are treated with hexamethyldisilazane for hydrophobization. [Inorganic fine particles 1] having an average primary particle diameter of 5 nm was obtained.

[0482] (2) Synthesis of organic particle emulsion

[0483] In a reaction vessel equipped with a stirring bar and a thermometer, add 683 parts of water, 11 parts of sodium salt of methacrylic acid ethylene oxide adduct sulfate (Eleminol RS-30, manufactured by Sanyo Chemical Industry Co., Ltd.), 83 parts Parts of styrene, 83...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com