Portable electric driven compressed air gun

A compressed air and air compression technology, applied in the field of shotguns, pneumatic guns, paintball guns, and air rifles, can solve the problems of difficulty in operation, inefficient use, and cannot support rapid shooting operations, and achieve simple structure and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] While the following relates to a preferred embodiment of the design, those skilled in the art will appreciate that changes can be made in materials, part descriptions and methods of actuation without departing from the spirit of the invention.

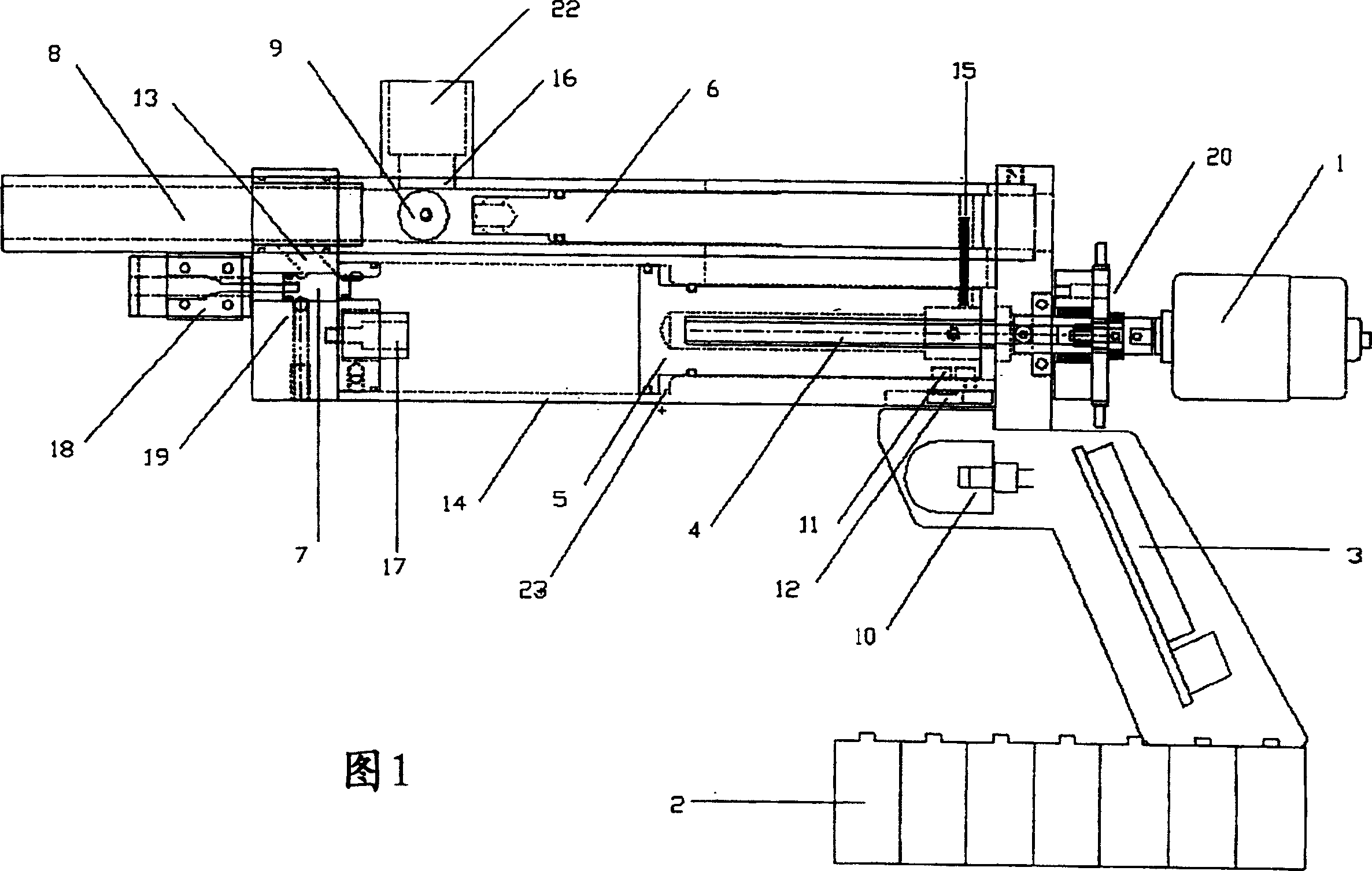

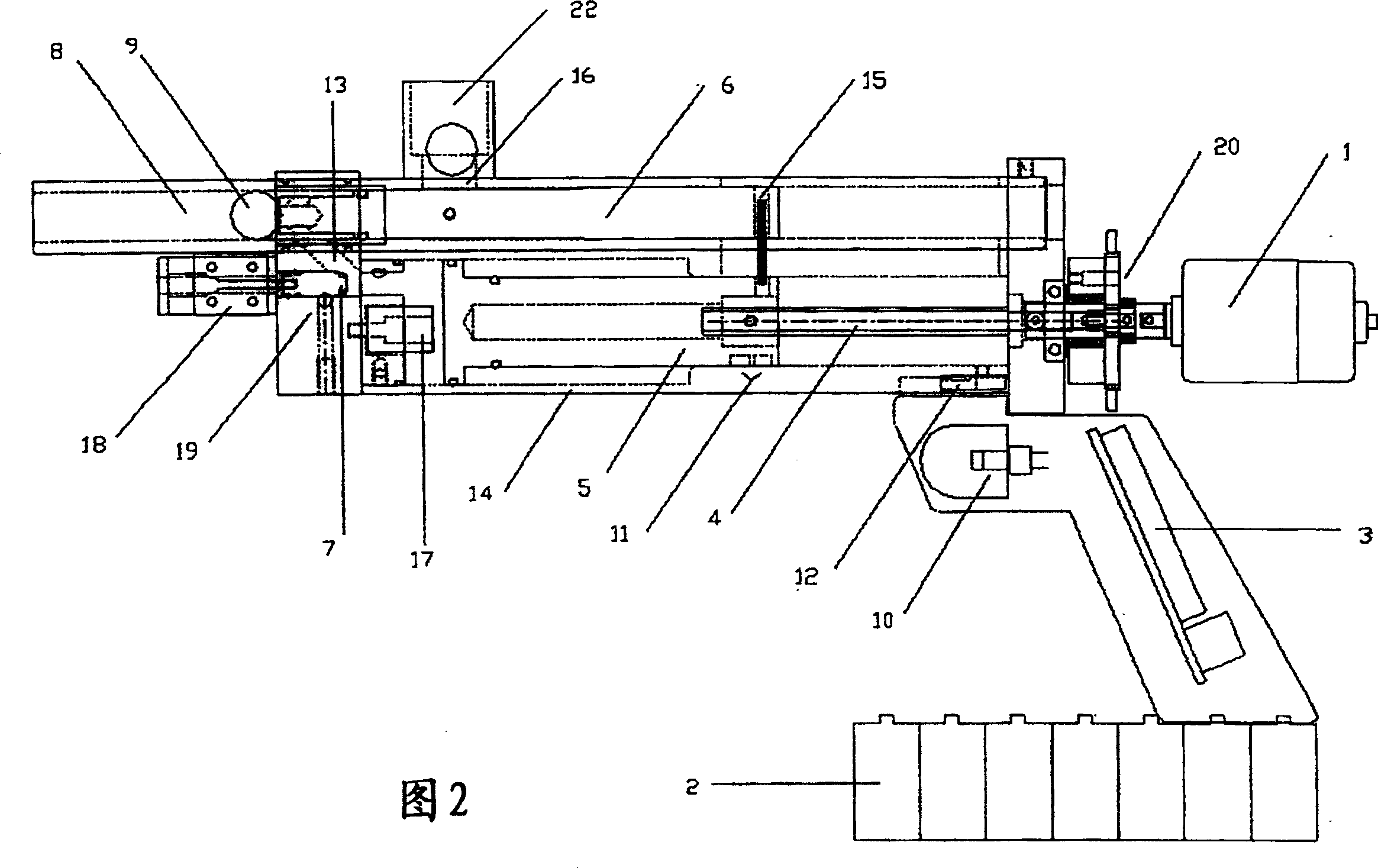

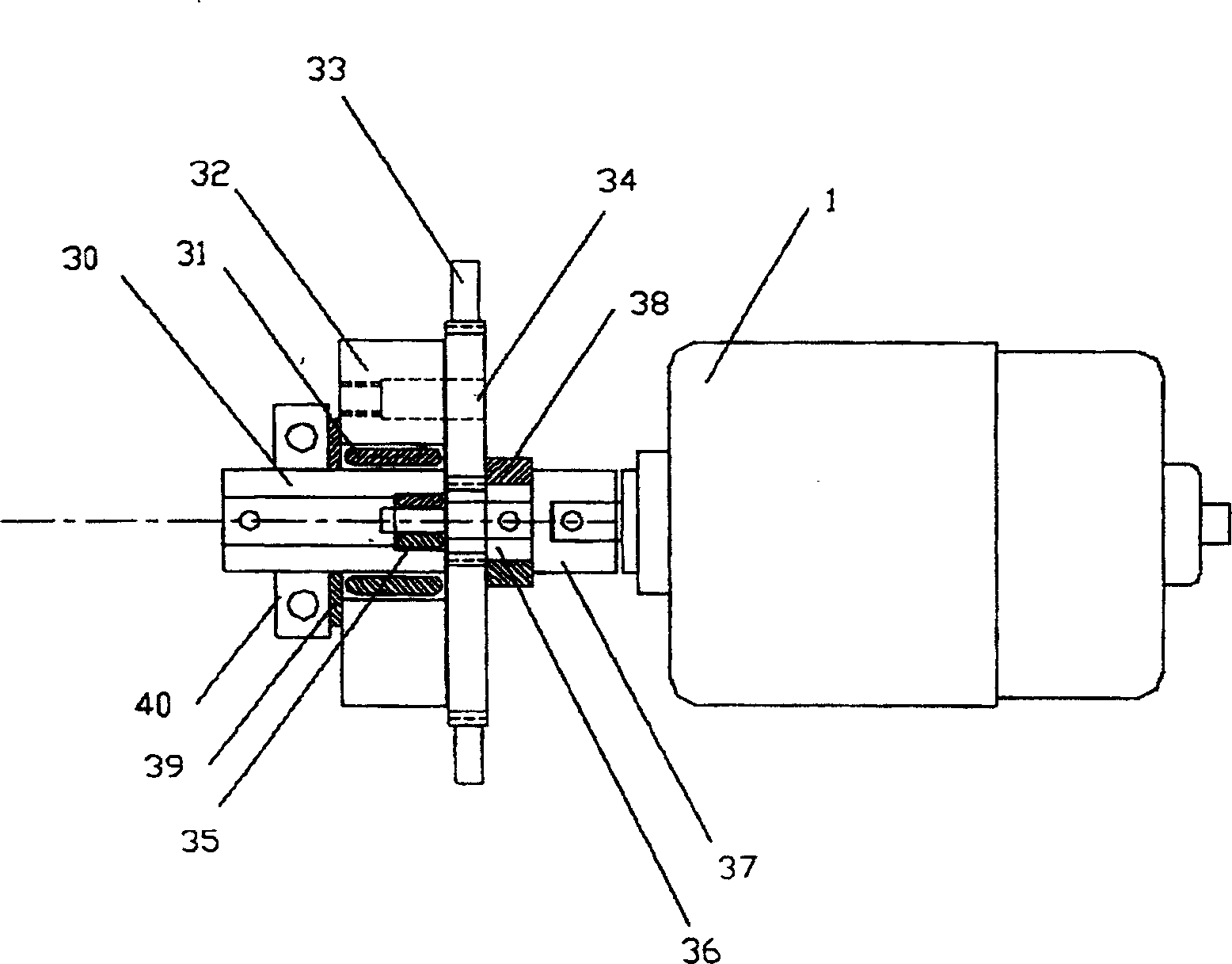

[0035] Referring to Figure 1, in the preferred embodiment, the user depresses the activation switch 10 or trigger. This causes power to be directed from a power source 2 such as a battery to the motor 1 by the control circuit 3 . The preferred control circuit is described in more detail later, but can be as simple as any means used to connect and disconnect power to the motor to allow the air compression and pellet firing cycles. Motor 1 starts to rotate, causing energy to be stored in the rotating elements in the system. The system includes a motor rotor and a lead screw 4 . Lead screw 4 is coupled to motor 1, preferably via a planetary gear train, as further described in image 3 shown in . Furthermore, the transmission is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com