Mixed type organic phosphate polypropylene nucleating agent and method for preparing the same

A polypropylene nucleating agent and organophosphate technology, applied in the field of polypropylene nucleating agent and its preparation, can solve the problems of poor adaptability, uneven mixing, complicated process, etc., to improve the flexural modulus and meet the requirements of flexibility , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

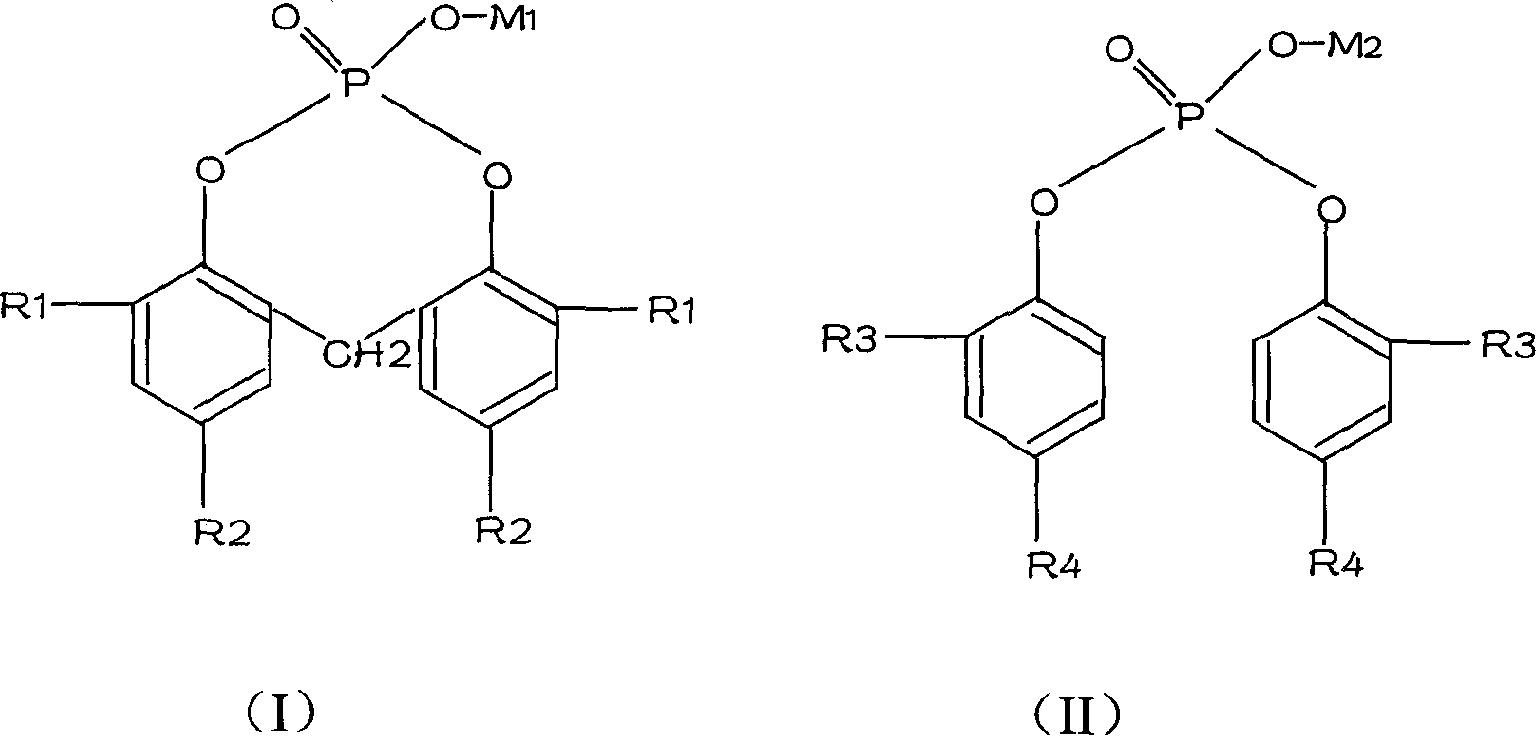

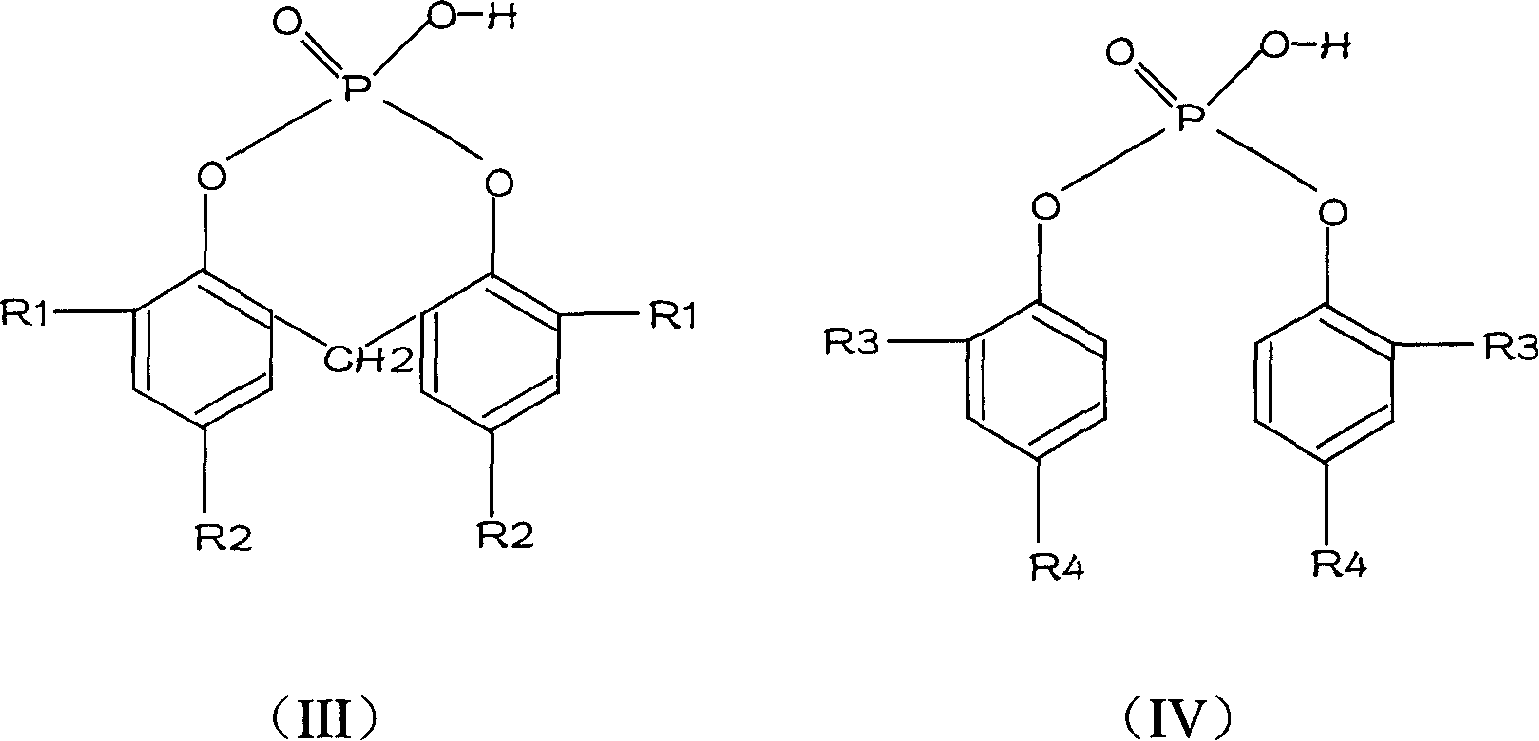

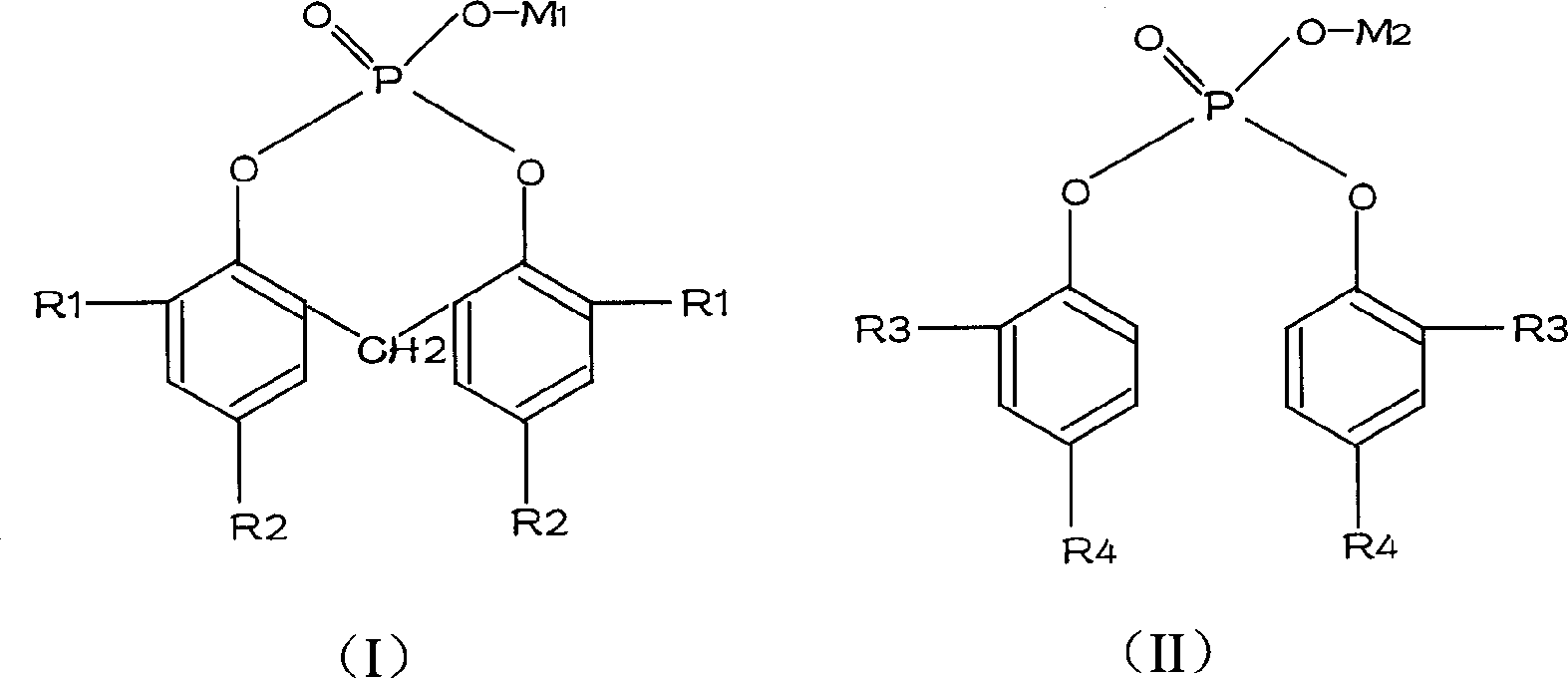

Method used

Image

Examples

Embodiment 1

[0045] Weigh: 30 grams of bis(2,4 di-tert-butylphenoxy) phosphate, 19.2 grams of 2,2′-methylene-bis(4-methyl, 6-tert-butylphenoxy) phosphate , 10.8 grams of 2,2'-methylene-bis(4,6-di-tert-butylphenoxy) phosphate.

[0046] In a three-necked flask with a stirrer, add acetone and water at a volume ratio of 2:1 to obtain 400 ml of a mixed solvent, dissolve the above three organic phosphates in the mixed solvent, and add 24.8 ml of 30% NaOH aqueous solution to neutralize Salt formation, control the reaction temperature to 20 ℃, pH 10.2, after 30 minutes of reaction, evaporate the acetone, filter, wash the white solid obtained, vacuum dried at 90 ℃, to obtain a white solid powder, namely bis(2,4 di-tert Butylphenoxy) sodium phosphate, 2,2'-methylene-bis(4-methyl, 6-tert-butylphenoxy) sodium phosphate and 2,2'-methylene-bis(4, 6-di-tert-butyl phenoxy) sodium phosphate mixed type organic phosphate polypropylene nucleating agent.

Embodiment 2

[0048] Weigh: 16.8 grams of bis(2-tert-butyl, 4-methylphenoxy) phosphate, 2,2′-methylene-bis(4-methyl, 6-tert-butylphenoxy) phosphoric acid 21.6 g of ester and 9.6 g of 2,2'-methylene-bis(4,6-di-tert-butylphenoxy) phosphate.

[0049] In a three-necked flask with a stirrer, add acetone and water in a volume ratio of 2:1 to obtain 400 ml of a mixed solvent, dissolve the above three organic phosphates in the mixed solvent, and add 34.4 ml of 30% NaOH aqueous solution to neutralize Salt formation, control the reaction temperature to 28°C and pH to 9.8. After reacting for 30 minutes, distill off the acetone, filter and wash the white solid obtained with water, and then vacuum dry at 90°C to obtain a white solid powder, namely bis(2-tert-butyl) , 4-methylphenoxy) sodium phosphate, 2,2'-methylene-bis(4-methyl, 6-tert-butylphenoxy) sodium phosphate and 2,2'-methylene-bis (4,6-Di-tert-butylphenoxy) sodium phosphate mixed type organic phosphate polypropylene nucleating agent.

Embodiment 3

[0051] Weigh: 8.1 g of bis(2-tert-butyl, 4-methylphenoxy) phosphate, 15.12 g of bis(2,4 di-tert-butylphenoxy) phosphate, 2,2′-methylene 30.78 g of yl-bis(4,6-di-tert-butylphenoxy) phosphate.

[0052] In a three-necked flask with a stirrer, add acetone and water at a volume ratio of 2:1 to obtain 400 ml of a mixed solvent, dissolve the above three organic phosphates in the mixed solvent, and add 27.2 ml of 30% NaOH aqueous solution for neutralization Salt formation, control the reaction temperature to 34°C and pH to 8.5. After 30 minutes of reaction, distill off the acetone, filter and wash the white solid obtained with water, and then vacuum dry at 90°C to obtain a white solid powder, namely bis(2-tert-butyl) ,4-Methylphenoxy) sodium phosphate, bis(2,4 di-tert-butylphenoxy) sodium phosphate and 2,2'-methylene-bis(4,6-di-tert-butylphenoxy) ) Mixed organic phosphate polypropylene nucleating agent of sodium phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com